Civil Engineering Reference

In-Depth Information

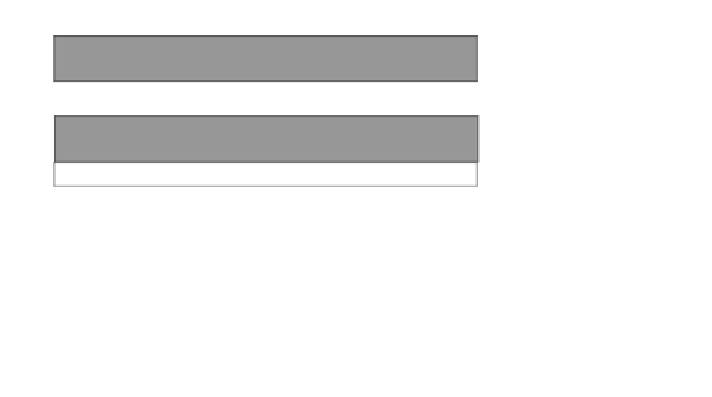

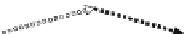

pinholesin theAl layer

PET 12 m

μ

Al 30-80 nm

adhesive1-2

m

μ

PE 50 m

μ

Fig. 7

Construction of a high-barrier laminate for a VIP

which could not be avoided, occur in the Al layers, the penetrating gas molecules

have to diffuse parallel to the pressure gradient until they hit upon a further pinhole

in the next Al layer (cf. Fig.

7

).

A typical thermal conductivity value for VIP used in building application is

about 0.005 Wm

-1

K

-1.

In principle, this value only yields for the core material

evacuated at a certain gas pressure. Because a vacuum insulation panel has a finite

dimension and thickness, there is always an influence of an enhanced heat flux via

the rims of a VIP. The heat flux depends on the effective in-plane thermal con-

ductivity of the used laminates and the length and thickness of the rims. This is the

reason why a VIP has to be regarded as an insulation system, and in a more correct

way, a heat transfer coefficient, the U-value, should be provided for VIP for a

certain dimension. The U-value in Wm

-2

K

-1

is defined by

q

¼

k

ð

T

Þ

T

h

T

c

Dx

¼

U

ð

T

Þð

T

h

T

c

Þ

ð

8

Þ

and describes the heat flux per unit area flowing through an insulation layer of

thickness Dx. The influence of the laminate type and panel size is depicted in

Figs.

8

and

9

. From Fig.

9

, it could be concluded that for VIP using high-barrier

laminates with an overall thickness of about 80 nm or less, thermal boundary

effects are negligible except for very small panels.

A further special property of a vacuum insulation panel is the fact that the VIP

envelope cannot be absolute vacuum tight. As mentioned above, gas molecules

could penetrate through pinholes and through the sealing areas into the VIP, and as

a consequence, the gas pressure will increase with time (Schwab et al.

2005c

).

Therefore, preferable microporous silica as kernel material (cf. Fig.

5

) in combi-

nation with high-barrier laminates is used to establish a long service time where the

gas pressure increases but not the thermal conductivity (Schwab et al.

2005a

,

b

).