Civil Engineering Reference

In-Depth Information

A

A

A

B

B

B

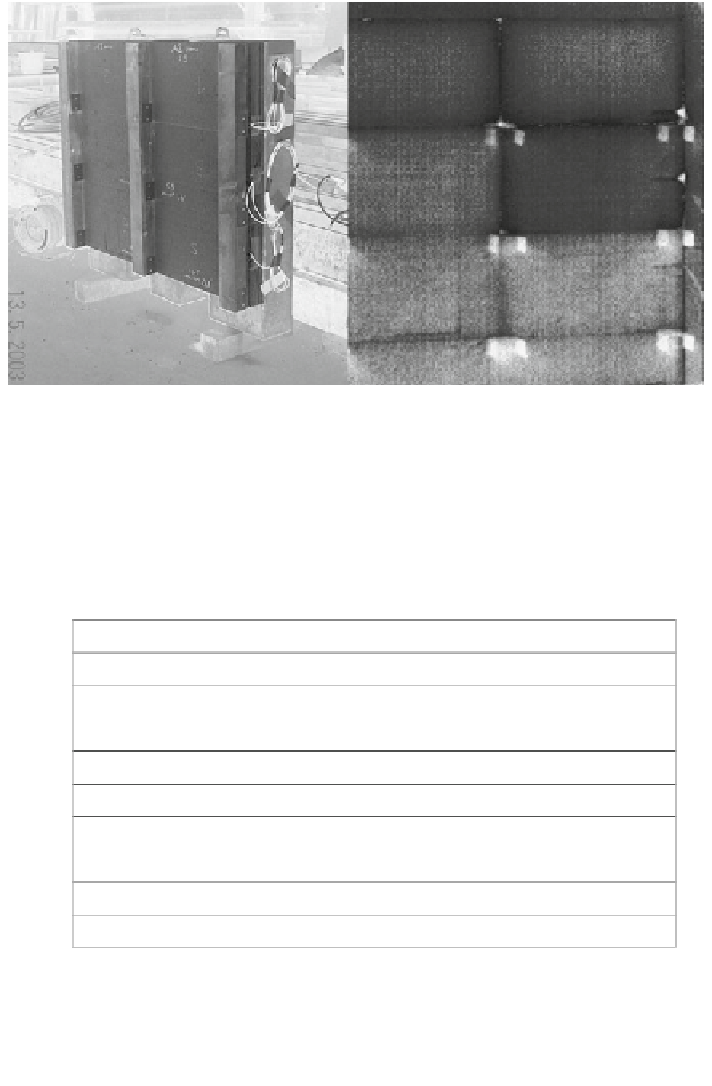

Fig. 8 Test construction for the investigation of thermal bridge effects while using VIP with

different envelope laminates. In a first group, the VIP laminates include a 7-lm aluminium layer

(A), and in a second group, VIP-applied laminates for the envelope contain only a 30-nm

aluminium layer. Left 6 VIP were mounted on a temperature-controlled concrete wall and

covered with 20-mm polystyrene foam insulation. Right The thermal image shows enhanced

temperatures for VIP with the pure aluminium enclosure

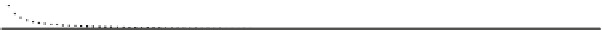

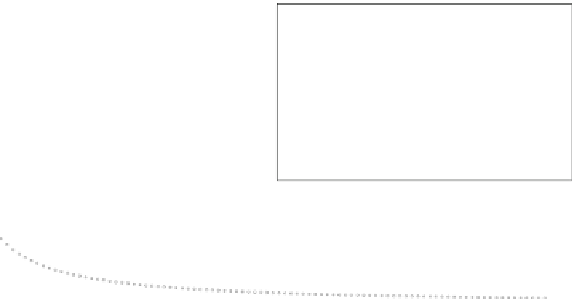

200 µm stainless steel envelope

1

laminate with an 8 µm aluminum layer

0.9

0.8

laminate with an 80 nm aluminum layer

0.7

infinite extended VIP

0.6

laminate with 80 nm aluminum and an air gap of 5

mm between adjacent VIP

0.5

0.4

0.3

0.2

0.1

0

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Length of a square-shaped paneel / m

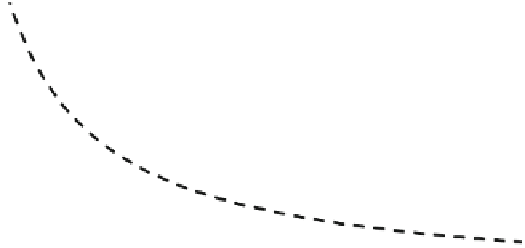

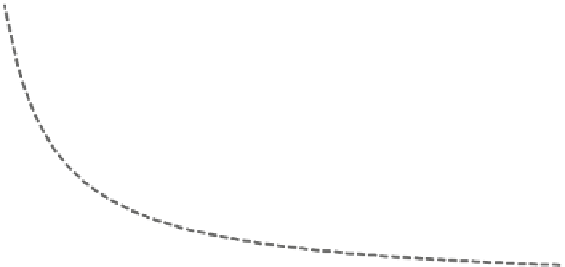

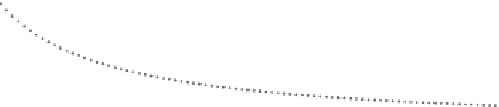

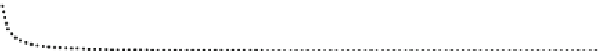

Fig. 9 Calculated average U-value of vacuum insulation panels (VIP) as a function of panel size

for different laminate types. The values for the infinite extended VIP (full line) represent the U-

value for the core material not taken into account thermal boundary effects