Civil Engineering Reference

In-Depth Information

of the history of vacuum insulation is given in Fricke et al. (

2005

,

2008

). VIP

technology for building application is described in literature in detail (Binz et al.

2005

; Simmler and Brunner

2005

; Baetens et al.

2010

).

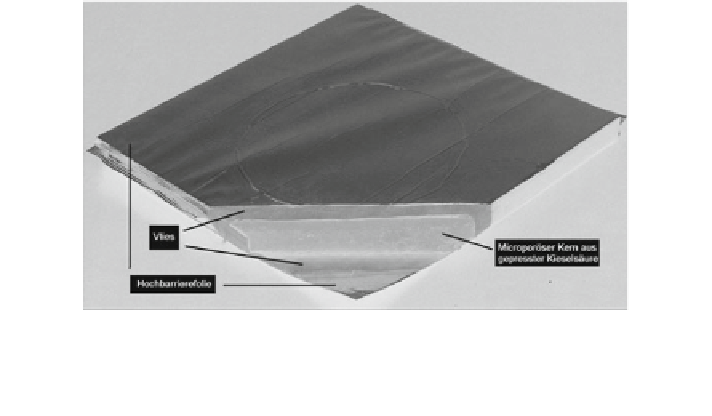

For flat insulation panels, which are applicable for building insulation, a

microporous kernel is used, which consists of a pressed silica powder in the most

cases (cf. Fig.

6

). Additionally, an infrared opacifier is added to the silica powder

to reduce the radiative heat transfer. The pressed silica core is embedded in a core

bag to enable a further dustless manufacturing of the final VIP. The filled core bag

will be enfolded by a multilayer envelope film. This package will be evacuated

down to 1 mbar and sealed within a vacuum chamber. The advantage of a kernel

made of fumed silica, which is evacuated at gas pressure of about 1 mbar, could be

seen in Fig.

5

. While for conventional insulation kernels like glass fibres or foams,

the effective thermal conductivity would immediately increase with gas pressure of

1 mbar, for the microporous fumed silica only at a gas pressure of about 100 mbar,

a significant increase could be recognised. This is a safety margin of 100 mbar

considering a typical gas pressure increase of 1 mbar per year by penetrating

nitrogen and water molecules through the high-barrier laminate and the sealing

rims.

In Fig.

7

, a typical design of a high-barrier laminate that used VIP is depicted.

The polyethylene (PE) layer is necessary to enable the thermal welding of the

laminate at VIP rims. The aluminium (Al) layers work as barrier layers against

penetrating air gas molecules, e.g. nitrogen, oxygen and water vapour. It is

important to use more than one thin Al layer in the range of several nanometres,

e.g. two or three, to reduce thermal heat transfer via these layers and therefore a

thermal bridge at the VIP rims. The minimum thickness of the adhesive layer

embedded between the two metal layers is also important. If pinholes, i.e. defects

welded

seam

core bag

pressed silica

core with

opacifier

multi-layer

envelope film

Fig. 6 Construction of a vacuum insulation panel (VIP) used for building insulation: a pressed

silica core is embedded in a core bag to enable a further dustless manufacturing of the final VIP.

The filled core bag will be enfolded by a multilayer envelope film. This package will be

evacuated and sealed within a vacuum chamber