Civil Engineering Reference

In-Depth Information

After the house is closed in and the electric wiring

is done, a second strip of lath is cut to fit in the same

manner and applied between logs from inside the

house. The inside lathing need not be sloped, but it's

easier to trowel the mortar onto it if it is.

The next step is parging cement mortar about half

an inch thick onto the metal lath on each side. Then,

when it's dry, we apply two coats of exterior-grade

masonry sealer to the outside.

Preparation

About chinking green logs — don't. Although it might

seem like the drying logs will settle and the chinking

will stay tight, it won't. The log face is wider than the

notch, so it shrinks more than the notch lets it settle,

and the crack opens. The fiberglass inside expands so

there's no space. And even without the caulk, there

won't be a draft but a crack will open.

Any green logs, whether in new construction or as

replacements, must season at least a year before

chinking. You can fit the lath between the logs right

away and then plaster later on if you like, but the lath

is liable to rust unless you paid extra for the galvanized

type. It's also important to make sure the logs aren't

heavily rain soaked before chinking. Summer and fall

are the best times to chink, when the weather is dry.

Allowing the logs to season is important. A 12-inch-

wide log can shrink as much as half an inch. That's

four inches for an eight-foot-high wall. So the whole

house shrinks down as it seasons. If verticals like door

and window facings, interior stud walls, and stair sup-

ports are installed before this seasoning takes place,

then they either buckle or prevent the logs from set-

tling in one area, which opens larger cracks below.

This brings up the question of how wide the chink-

ing cracks should be. Early builders tried to leave as

narrow a space as possible between logs to minimize

chinking (unless the house was to be sided over imme-

diately, as many were). As my first experience showed,

this doesn't work very well. I like two inches of space

as an absolute minimum, but four inches is better and

looks better with wider logs. I restored a house in Ken-

tucky with some whopping 10-inch cracks between

logs and one in Virginia that used whole bricks up on

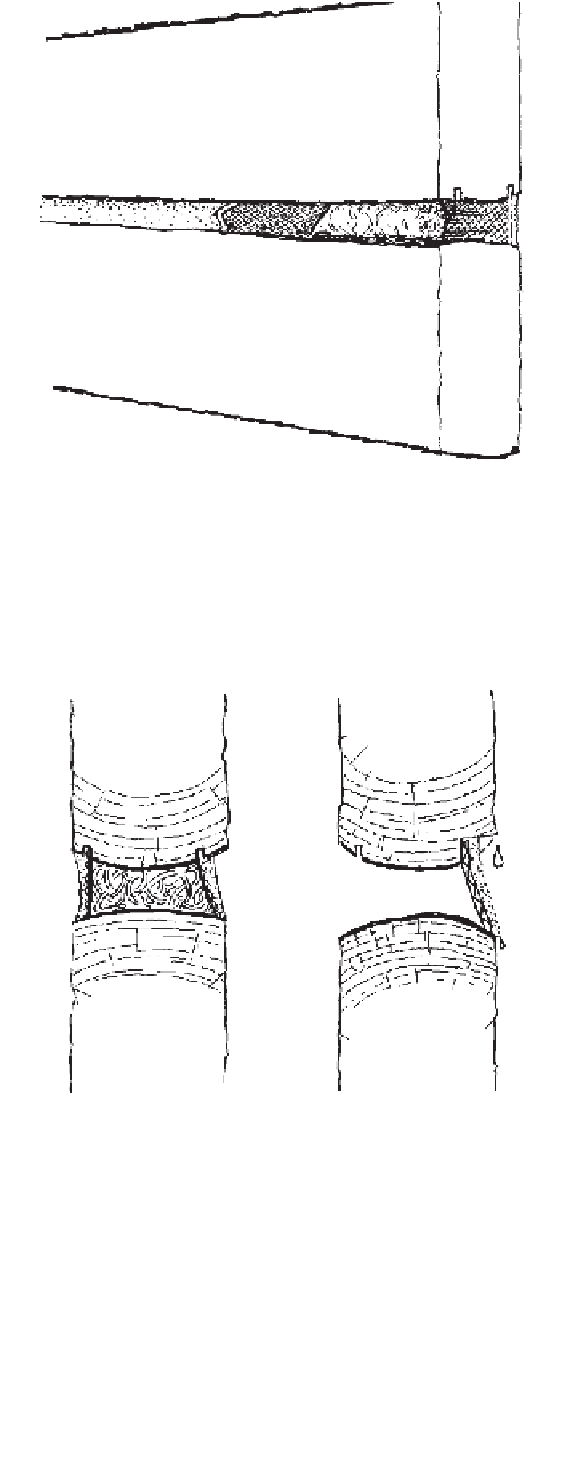

Pack fiberglass insulation against the exterior wire lath. The interior

lath can be nailed in more vertically than the exterior, since the

interior does not need to shed water. The insulation is sandwiched

between the mortared laths. Both mesh and mortar should be

sloped out at the bottom to drain water away from the log below.

Chinking must be tucked under the lower corner of the logs so rain

won't get behind it. If a log is rounded, cut a notch in it to leave a

corner for rain to drip off. It is less critical for interior chinking to be

sloped; in fact, some people prefer a more vertical, smooth look to

an interior wall. It is the fiberglass packed between the two layers

of chinking that provides the insulation, keeps out the wind, and

“moves” with the log movement as the weather changes.