Civil Engineering Reference

In-Depth Information

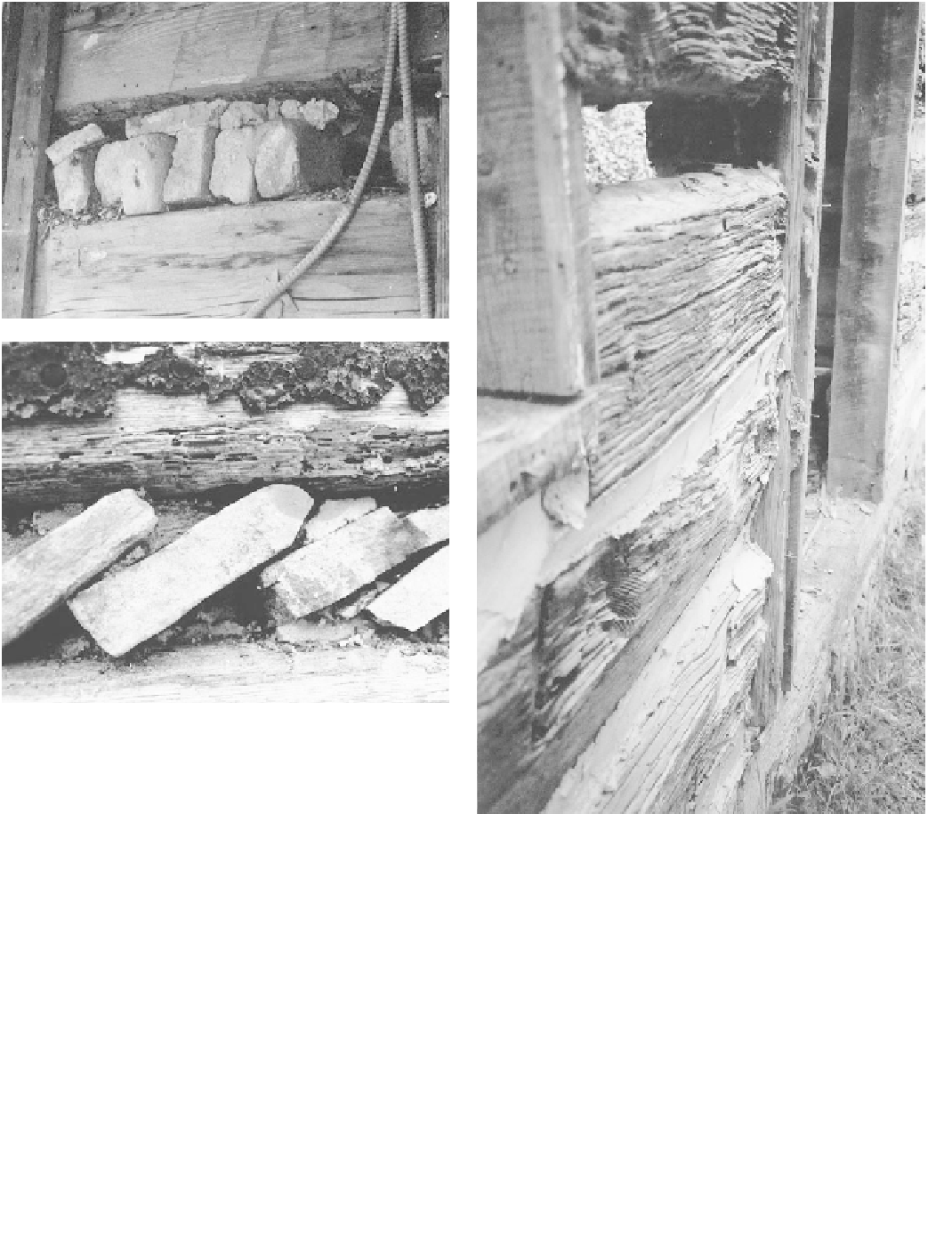

Here are examples of why chinking in cabins in previous eras failed.

Brick and stone “chinks” smeared with mud or concrete moved with

the change in weather and allowed rain to damage the logs. The aim

today is to re-engineer the chinking to make sure that rain doesn't

get inside.

side of each log, and it's for the strip of reinforcing wire

lath to go up into. When we tried shaping this top edge

of the lath and nailing it in at the tucked-in angle to

the irregular log underside, we lost a lot of time.

Nobody wanted to do wire-lath duty. Next, I cut the

strip of metal lath with manual or electric tin snips. It

should be a little wider than the space and should be

fitted flat up into the groove and slope out from top to

bottom.

The top edge, being straight, goes into the groove

no matter how irregular that log surface is, and the

slack is taken up. At the bottom, we trim with tin snips

to fit the lower log surface, and nail the lath with six-

penny nails about half an inch in from the face of the

log beneath.

I usually parge the exterior first (after the doors,

windows, and gable ends are in) to get the house

weather-tight. Plumbing and electrical can be run in

between the logs on the interior before doing that side.

Fiberglass batting is stuffed into the crack to fill it to

within about one inch of the inner wall surface. I buy

the paper-backed rolls, which can be divided into

strips of the right width with a handsaw by cutting

through the roll. (This is like slicing an ice-cream roll.)

Then I strip off the paper to get a tight fit. I favor six-

inch-thick rolls.