Civil Engineering Reference

In-Depth Information

Flashing

Use flashing in valleys, around dormers and wings,

around chimneys, and on all ridges. The aluminum

kind is cheap and pliable, and less trouble than old off-

set printing plates or flattened cans. We use copper

flashing today, with copper nails, because it lasts

longer. Copper tones down to a neutral brown; none

of it shows. Always use the same kind of metal in nails

and flashing; dissimilar metals corrode each other.

Chimney Space and Flashing

Your chimney will go through the roof somewhere,

regardless of the positioning of the fireplace in your

house. You may have thought to leave a section of

decking out for the chimney to come up through. I

never do; I saw out the section later for a better roof-

to-chimney fit. Anyway, don't roof this space, usually

a three-foot-wide cut in the eave dimension.

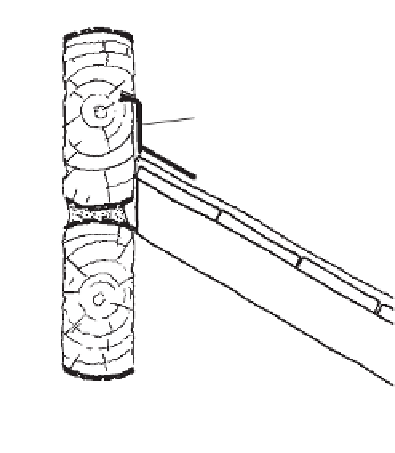

Flashing is imperative when a roof for a porch or lower addition

abuts a log wall. Cut a groove into the log one inch deep and

insert the flashing the full length of the roof. Use copper if the

roof is made of shakes or copper. Use galvanized metal or

aluminum if the roof is made of that metal.

Guttering

simple, supported on brackets of wood or metal. How-

ever, downspouts are harder with wooden gutters.

Guttering your cabin is a necessity. It keeps runoff

from soaking the ground under the foundation and

helps keep water from getting into a basement. Gut-

ters aren't pretty, but they're useful. We use half-

round, usually copper, gutters with downspouts piped

away from the house.

Remember not to let dissimilar metals touch; a

metal roof and copper gutter straps will corrode each

other. This applies to all places where you might use

metals — wall flashing, porches, snowbirds, chimney

flashing, conjoined roofs, etc.

Also, if you gutter, you'll want to use snowbirds to

hold the snow till it melts, so it won't tear the gutters

off. Again, use similar metals — bronze for a copper

roof, zinc alloy for a galvanized roof.

By all means, install a permanent screen over the

gutters to keep out leaves. Decaying leaf acid will cor-

rode any metal.

If you do not have access to commercial guttering,

or if you just like the look of wood, you many build gut-

ters of wood. Cypress is expensive, but long-lasting.

Pressure-treated wood will also serve. A vee-trough is

The Gables — Outside and Inside

Close the gable ends in conventional stud-wall fash-

ion, laying a 2≈4 or 2≈6 sill on the top log if you want

it more even. With round or unevenly hewn rafters,

you can spike another 2≈4 or 2≈6 to the undersides of

these to nail the gable wall to. Frame windows con-

ventionally, remembering to leave space at the fire-

place end for the chimney.

Clapboard, board and batten, and shakes were

commonly used for the exterior of the gables. These

walls should be insulated. And you will want to finish

them with interior wall covering. Here, I favor panel-

ing grade of 1≈12 lumber used vertically. You'll add

horizontal 2≈4s, called fire-stops, to nail to. It's a

simple operation to run this wall material through a

spindle shaper or dado blade to shiplap it. Or you can

purchase tongue-in-groove lumber, which is more

expensive. Either will keep cracks from opening up if

there is shrinkage.