Civil Engineering Reference

In-Depth Information

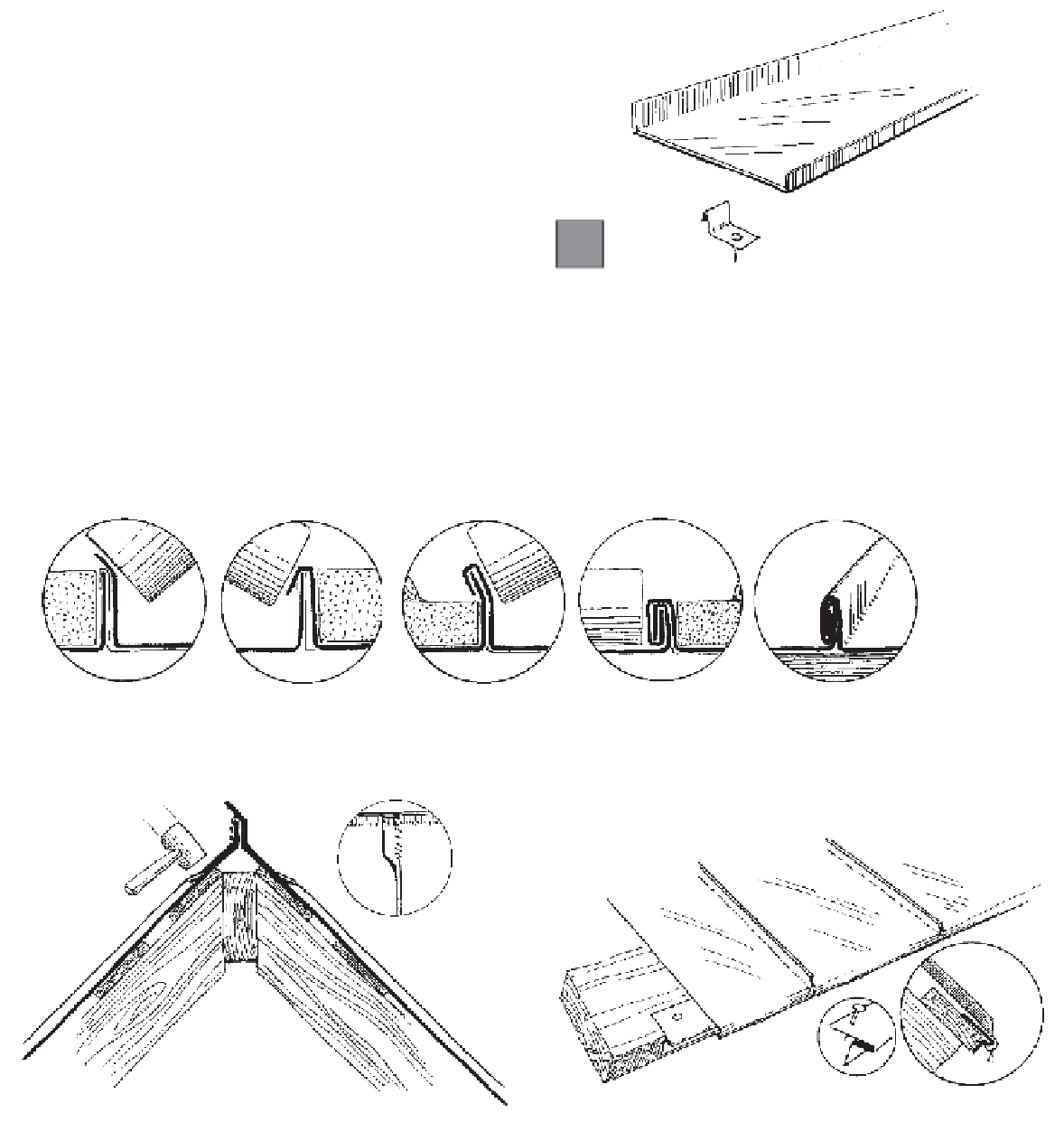

Building a Standing-Seam Metal Roof

Standing-seam metal roofs have been used for so long in the eastern

and central United States they have become historic. For many years,

the metal was not available in this country, and was imported from

England in short lengths. Now it is available in rolls of galvanized metal

or copper, as well as a modern version of English tin-coated sheet iron

called terne. Except for copper, the metal requires painting, however.

When painted, a metal roof lasts longer than wood or asphalt shakes.

The metal is installed over spaced or solid roof decking, with red

rosin paper or asphalt felt paper between. The method of installation

leaves no nail heads as points for potential leaks, and where properly

applied, no soldering or caulking is necessary.

1.

The procedure involves bending up the edges of the lengths of metal

at two different heights of the bend, forming “pans.”

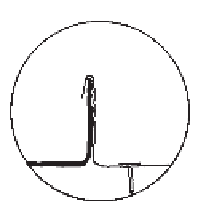

2.

The higher of these is placed next to the lower of the adjacent one. The lower has metal “clips”

nailed next to it and the clips are bent over the raised edge. (Clips are usually made on the job

site by cutting narrow strips of leftover metal into pieces about four inches long.)

3.

The higher edge is bent over and crimped over the lower, incorporating the clip and

covering the nail heads. A second bend and crimp locks the pan in place.

4.

At the top, the ridge is hammered flat. The end of the

pans is bent up, trimmed if necessary, and crimped

over the pans from the other side of the roof.

5.

The bottom edges are bent and crimped over specially

formed drip-edge (usually bought in 10-foot strips when

purchasing the rolls of metal) nailed in place. Like all

roofs, a metal roof best protects the house in conjunc-

tion with a good guttering system. Both the roof and the

gutter must be of compatible metal, or they will corrode.