Civil Engineering Reference

In-Depth Information

watch a tendency to slope inward or outward, as many

old houses do. That's of no great consequence until

you find your door won't open without swinging into

the floor. Use a level, and make sure all your full-

length logs are the same length from notch to notch.

Some delicate adjusting for alignment may have to be

done from time to time. I use a sledgehammer.

Ceiling Joists and Ceilings

At last, you're up to ceiling height. You should have at

least one log spanner above windows and doors, with

the facings attached after seasoning. If you cut deeply

into this log to get your door or window height, go up

another course before laying the ceiling joists. You'll

mortise these joists into the log, and you must be sure

there's enough wood left to support the weight.

You may not even want a ceiling or a loft, but the

joists are still a good idea; run them from front to back,

at right angles to the ridgeline. They are the truss

chords that tie the rafters together; they keep your

ridge from sagging and the rafters from pushing the

top logs apart. There is another way around this, how-

ever, which we'll talk about when we get to the roof.

Let's assume that you do want a ceiling, and a floor

for the loft. These can be two layers, on top and bottom

of the joists, with insulation between. But because

you'll be using the loft, let's not insulate it from the

downstairs heat. And let's keep the ceiling beams vis-

ible. Massive, hewn joists support better, and look

better by giving a reassuring feel of strength and shel-

ter. I hew them with the broadaxe, then adze for addi-

tional smoothness. Fancy houses in the old days

sported beaded joists, worked with a hand plane.

A 6≈8 joist is both aesthetically pleasing and strong.

But for a house deeper than say 16 feet, building codes

will require something deeper, like a 6≈10 or 6≈12.

Lay the joists a minimum of 4 feet apart, or 3 of them

in a 16-foot house interior, 4 in a 20-foot interior. They

should be half-dovetailed into the top front and back

logs, so that they tie these walls together. Sometimes

they were simply mortised, but this gave no bracing

against outward thrust unless they were also pegged.

Dress the top surfaces of these logs and joists carefully,

as you did your floor joists, because you'll be nailing

flooring on top of them.

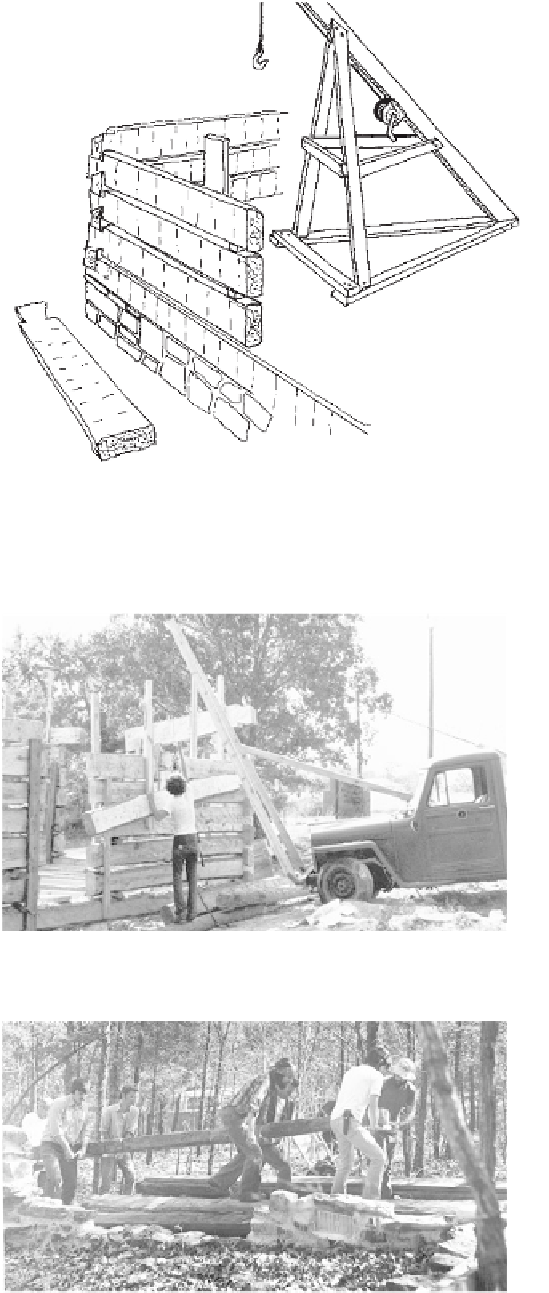

This hoist is the invention of Peter Gott, master log builder from

Marshall, North Carolina. Peter says he is glad to share this device

with other log builders, because we all borrow building techniques

from each other whether or not we realize it. It's used on a subfloor

to reach over each wall to lift outside logs from the inside.

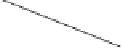

This simple lifting device utilizes a pair of braced 2x4s (gin poles) from

the bumper of a pickup truck. Lifting is by a ratchet hoist or come-along.

Enough people can carry logs and put them up by hand, as in this

scene from Murphy's log raising. The stone-corner foundation was

filled in after the cabin was up.