Civil Engineering Reference

In-Depth Information

points for balance. Once the rig is in place, it's a good

idea to support each end of the bumper with a block,

to take the weight off the springs and spindles. I've

since replaced this with a 1951 Dodge Power Wagon

with winch, and braced two-inch steel pipe for the

gin poles.

On very tall houses, we sometimes found my gin

poles weren't tall enough. That happened on our Vir-

ginia house, and I was resigned to cutting and weld-

ing in extensions. Then, a woman who worked for us

suggested driving the Land Rover up onto my flatbed

truck to make it taller. It took 20 minutes, and it

worked.

At a house-raising, four men with ropes can haul

each log up from the top while others push from

below. Or you can use skid poles with the ropes.

I copied Peter Gott's hand lift a few years ago, and

it works well on relatively small logs, say up to 20 feet

and maybe 12-inch faces. It's oak, cut 1∏ inches thick

and braced often to keep the weight down. I lay a sub-

floor to use the lift so it can be moved around from

wall to wall. Peter uses big casters on his, which is

heavier with more lifting capacity. I've lifted 400

pounds with mine, with the lightweight boat trailer

winch on it. This device lets you lift logs from the

inside to each wall. Often a site won't give you access

to all four walls on the outside, so this is an advantage.

If you have room to maneuver and the money for

it, you may hire a knuckle boom. These are usually

mounted on 10-wheel trucks and have a reach of up to

30 feet or so. They're logging machinery, and a good

operator can take down a house with one in a hurry.

He can set it up quickly, too, but only if everything is

prenotched and ready. Fitting as you go is too slow to

make a knuckle boom efficient.

Check your log wall for vertical alignment as you go.

Particularly around windows and doors, you'll have to

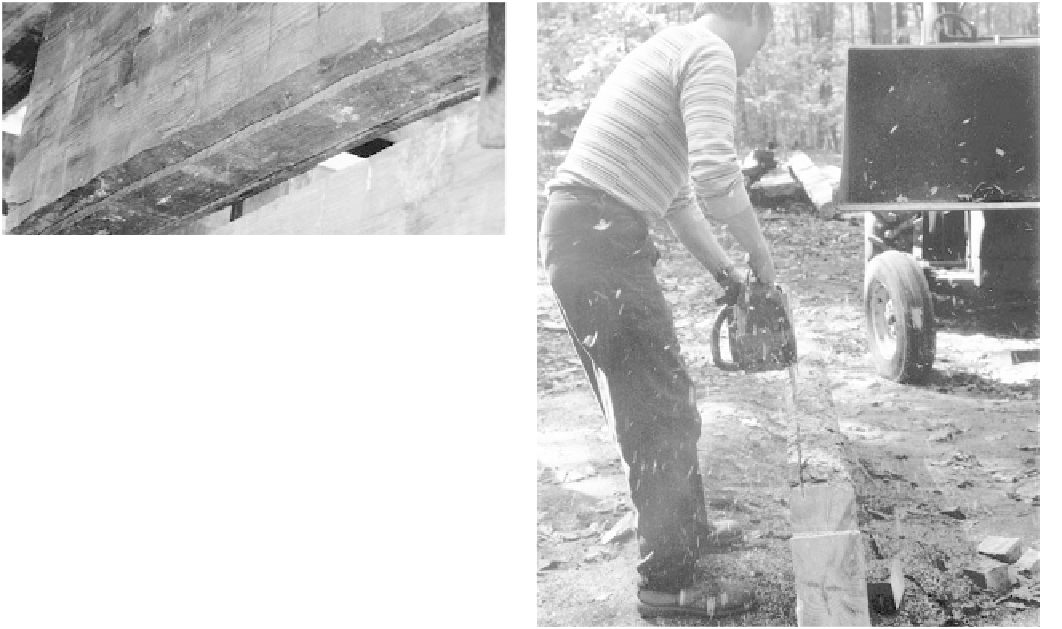

Cutting a groove for the chinking wire mesh that will hold the masonry

mortar. Two grooves are cut on the underside of the log (above left)

with a chain saw, which greatly speeds up the chinking process, as

well as making the chinking look straighter and neater.

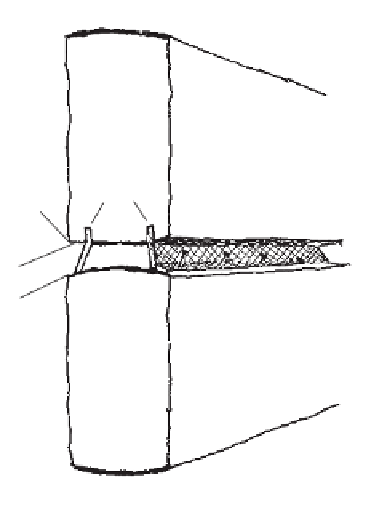

1 ⁄/™"

⁄/™"

Installing the wire mesh for mortar chinking is simplified by cutting

these grooves with a chain saw on the underside of each log. Log

surfaces sometimes need to be prepared for the chinking process.

The wire must slope outward so the finished chinking will shed water.