Chemistry Reference

In-Depth Information

7.3.1.4 evaluating specificity during sIm development

Another key parameter to evaluate during SIM development is specificity. The USP

and various ICH guidelines define specificity as the ability of a method to unequivo-

cally assess the analyte of interest in the presence of potential interferences (1, 2). In the

past, it was acceptable to evaluate resolution, peak shape, and tailing factors to measure

and document specificity. However, starting with USP 25, and as a direct result of the

ICH process, it was recommended that a peak purity test based on photodiode array

(PDA) detection or mass spectrometry (MS) be used to demonstrate that a given peak

was pure—that nothing co-elutes.

Modern PDA technology is a powerful tool for evaluating specificity. PDA detec-

tors can collect spectra across a range of wavelengths at each data point collected

across a peak, and through software manipulations involving multidimensional vec-

tor algebra, compare each of the spectra to determine peak purity. In this manner,

PDA detectors today can distinguish minute spectral and chromatographic differ-

ences not readily observed by simple overlay comparisons [18-20]. To be successful,

three components are required:

1. A UV chromophore, or some absorbance in the wavelength range selected

2. Some degree of chromatographic resolution

3. Some degree of spectral difference

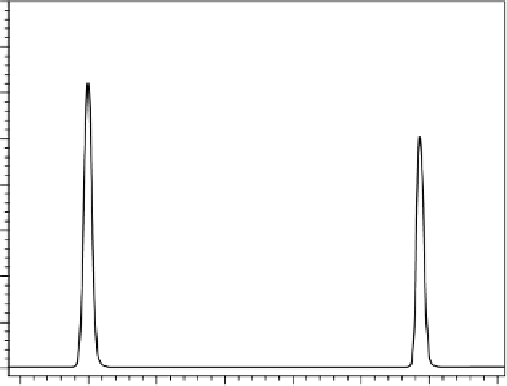

Figure 7.4 shows an example of a partial reversed-phase LC separation, where, by all

appearances, the peaks are certainly well resolved, sharp, and symmetrical.

An examination of peak two indicated the peak was pure. However, a close exam-

ination of the spectral information related to peak one reveals a different situation.

0.80

0.70

Peak6 - 16.986

0.60

Peak7 - 21.862

0.50

0.40

0.30

0.20

0.10

0.00

16.00

17.00

18.00

19.00

20.00

21.00

22.00

23.00

Minutes

FIgure 7.4

Example PDA chromatogram used to evaluate specificity/peak purity.