Civil Engineering Reference

In-Depth Information

4.1.2 Mechanical-Based EEC Determination Procedure

In determining the EEC using this method, the mechanical power profiles of

conventional compression and EAF compression tests are needed. As mentioned,

the EEC is a ratio between the usable applied electrical power and the over-

all applied electrical power. Further, any portion of the overall applied electrical

power that is not utilized to assist plastic deformation is assumed to contribute

directly toward heating the workpiece. The EEC can be described in equation form

as Eq. (

4.1

).

ξ

=

(

P

conv

−

P

EAF

)

P

conv

(4.1)

where

P

conv

is the mechanical power profile of a conventional compression test

and

P

EAF

is a mechanical power profile of an EAF test. The difference between

the mechanical power profiles of a conventional and EAF test provides the mag-

nitude of electrical power that contributed toward aiding the plastic deformation.

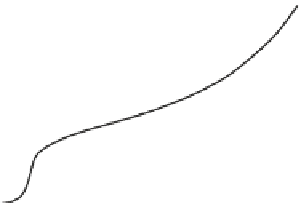

Figure

4.2

shows the mechanical power profiles for the mentioned compression

tests, where Al6061 specimens (9.5 mm height

×

6.4 mm diameter) were com-

pressed at 25.4 mm/min to a final displacement of 6.4 mm. Please note that the

“Baseline” and “EAM” tests in the figure have the exact same test parameters,

with the exception of the “EAM” test having a current density of 20 A/mm

2

applied to the specimen during deformation. The Baseline/EAF mechanical power

profiles cannot be compared unless the following test parameters are the same:

stroke, die speed, starting specimen size, and preload.

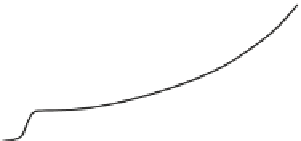

The next step is to determine the actual EEC profile. Although the EEC is

complex, an initial method to simplify the relation was to use an average value

approximation. To determine an average EEC, a coefficient profile was cre-

ated by plotting the coefficient versus time for each respective current density, as

shown in Fig.

4.3

. Once the coefficient profile was established, an average coef-

ficient for each current density was determined using a flat-line approximation.

This type of approximation is sufficient for initial model verification and is fairly

accurate except with the 60.8 A/mm

2

test. To better characterize the EEC profile,

Fig. 4.2

Determination

of the electroplastic effect

coefficient (EEC) [

3

]. In this

figure, the differences in the

mechanical power profiles are

used to determine the ratio of

“useable” applied electricity,

quantified by the EEC

16

Baseline

14

12

EAM

10

8

6

4

2

0

0

5

10

15

20

Time (s)