Civil Engineering Reference

In-Depth Information

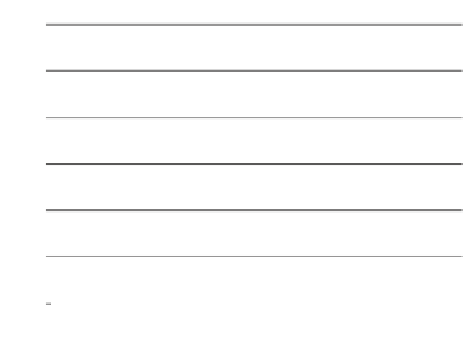

Fig. 4.1

Mechanical

power profiles (12.7 mm/

min) [

1

]. The mechanical

power profiles decrease in

magnitude as a higher current

density is applied

12

CD15

10

CD10

8

Baseline

6

CD25

4

CD20

2

0

0

5

10

15

20

Time (s)

mechanical work with respect to time, thus aiding the deformation (i.e., imparting

energy onto the dislocations and facilitating their movement by providing enough

energy to overcome lattice obstacles). The specific steps to solve for the EEC

using the mechanical-based method are as follows. Within the following sections,

these steps will be carried out using EAF compression tests on Al 6061-T6511.

1. Run a conventional and an EAF compression test. Note that these tests need

to be run at the same parameters (i.e., die speed, deformation stroke, initial

preload, and starting specimen size), with the exception of the applied current

for the EAF test. It is also recommended to run several replicates of each test to

verify that the results are repeatable.

2. Plot the mechanical power versus time profiles. In Fig.

4.1

, four different start-

ing current densities were tested; therefore, four different sets of EAF tests and

one set of conventional compression tests were needed to construct the profiles.

3. Determine the difference between the two power profiles and normalize it with

respect to the conventional forming power profile.

4.1.1 Experimental Setup and Procedure

The experiments for this section involved running conventional compression tests

and EAF compression tests at several starting current densities. The experimen-

tal data used in determining the EEC are from EAF compression tests run on Al

6061-T6511 specimens, by Perkins et al. [

2

]. The initial billets had a diameter

of 6.4 mm and a height of 9.5 mm. The compression tests were deformed to a

maximum stroke of 6.4 mm at a speed of 25.4 mm/min. The material parameters

and the friction conditions were determined by solving the model for a classical

test. After fitting the data, the following values were determined:

C

=

348 MPa,

n

=

0.04,

and

µ =

0.08.