Biomedical Engineering Reference

In-Depth Information

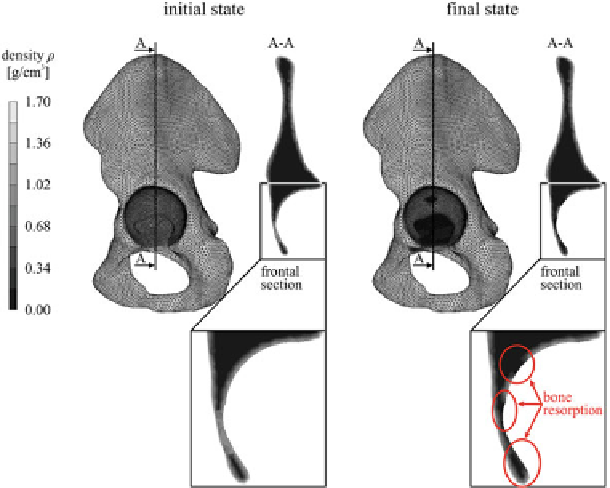

Fig. 2

Density distributions in the periprosthetic pelvis for the initial and final state [

17

]

3 Manufacturing Concept

It is planned to produce the patient-individual hip-cup prosthesis by a two-stage man-

ufacturing process consisting of the following steps: The first step is the production

of standardized titanium sheet metal components with undersize. These standardized

components can be produced by means of punch-die forming (“conventional” deep

drawing with punch, blank holder and die) or HPF in large-scale production. In the

second step the true-to-size enlargement of the produced standardized components

is executed. This enlargement is realized by double acting rubber-die forming with

adjustable elastomer lower die considering the present patient-individual geometries

of the acetabula.

In the following the production of the standardized titanium sheet metal com-

ponents is considered in detail. Thereby comparative simulations are presented for

the identification of the appropriate method for the first production step. Taking into

account these simulations, the HPF-process will be introduced to the production of

the standardized components.

3.1 Comparative Simulations

Comparative simulations were executed to identify the most convenient method to

produce the standardized prosthesis [

18

]. This preliminary investigation consists of