Civil Engineering Reference

In-Depth Information

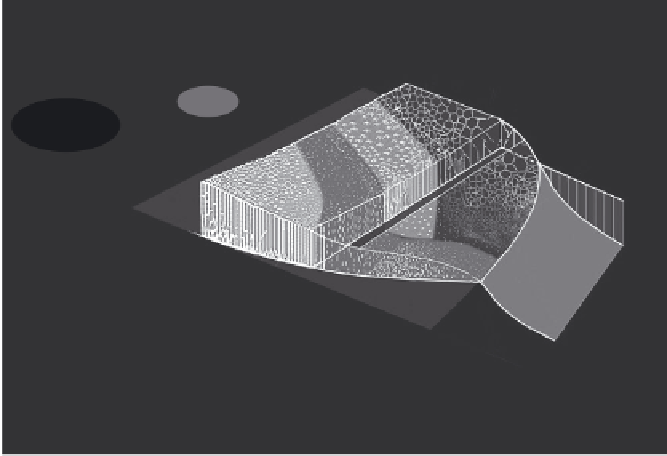

Recrystallized grain structure

Columnar grains

Cutout to show structure

Fine-grained,

nanocrystalline,

with preferred

orientation

Zone 3

Zone 2

T

*

Zone T

1

Zone 1

t

*

0.5

Region not

accessible

0.2

0.1

Porous,

tapered crystallites

separated by voids,

tensile stress

10

-1

Ion etching

zone

1

Densely packed

ibrous grains

10

Transition from tensile (low

E

*) to

compressive stress (high

E

*)

10

2

Line separating

net deposition

and net etching

Region not

accessible

10

3

E

*

Region of possible

low-temperature

low-energy ion-assisted

epitaxial growth

Region of max.

compressive stress Reduction of deposition

by sputtering, dense ilm,

amorphous for some materials

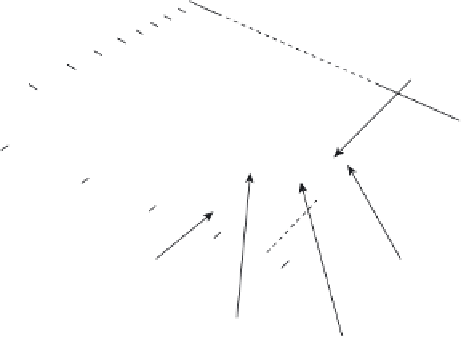

8.3

Schematic diagram showing nanostructures of thin fi lms made by

sputter deposition as a function of generalized temperature

T

* and

energy fl ux

E

*, and with

t

* denoting fi lm thickness. Ion etching can

take place at high energy fl ux. From Anders (2010).

A fi lm that is thicker than those in Fig. 8.1 develops a characteristic

nanostructure also over its cross section. Figure 8.3 is a recent extension

(Anders, 2010) of a well-known structure zone diagram, known as a

'Thornton diagram' (Thornton, 1977), and illustrates what happens. The

fi gure applies to sputtering and shows that the fi lm typically exhibits a

columnar structure oriented perpendicular to the substrate, and that this

structure depends critically on the deposition parameters, especially on the

energy of the sputtered species (in its turn related to the pressure in the

sputter plasma, typically comprised of argon) and the substrate tempera-

ture. The structure of an evaporated fi lm is found in the limit of a small

argon pressure; it was described already in the 1960s (Movchan and Dem-

chishin, 1969) and the modelling was subsequently refi ned (Barna and

Adamik, 1998; Hultman and Sundgren, 2001).

For many thin fi lm applications, there is a requirement for high durability,

which means that compact fi lms are wanted, and historically the sputter-

based technology was developed to prepare fi lms that were more durable

than those made by evaporation. Parameters leading to fi lms belonging to

'zone T' in the 'Thornton diagram' are then preferred. For other applica-

tions, however, it is desirable to make fi lms with a carefully chosen

Search WWH ::

Custom Search