3.

Weighing Equipment

When weighing the chemicals for a rocket propellant. you must always use an accurate scale because any deviation from the intended formula will make the rocket motor perform poorly. When I started this work I experimented with common spring scales, but the results were inconsistent and disappointing. Experience has taught me that, for propellant batches smaller than 2 kilograms, the scale should be accurate to 1/10 of a gram.

A Triple Beam Balance

The most practical and cost-effective scale is a triple beam balance, and the most popular ones are made by a company called “Ohaus”. You can buy a new balance from any scale or lab equipment dealer, and you’ll find used balances at auction sites on the Internet. At the time of this writing the most popular site is www.ebay.com. Type the name. “Ohaus”. into the eBay title-search engine. If you’ve taken a class in chemistry, you already know how to use a triple beam balance. For those of you who don’t, here is a brief explanation.

Adjusting the Balance

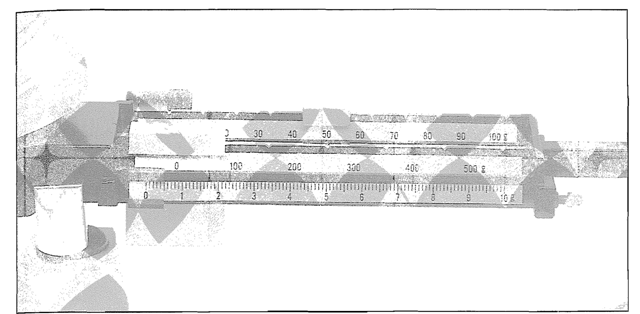

A triple beam balance gets its name from the three sliding weights that make it work. The weights can be moved back and forth along three separate scales, or “beams”, that read from 0 to 10 gms.. 0 to 100 gms.. and 0 to 500 gms. Before you can use the balance you have to adjust it to zero. To do so. place it on a solid, level surface, and remove everything from the sample pan. Then move the three weights back to their zero points (Figure 3-1). With a gentle, downward tap. start the pointer at the right end of the balance rocking, and watch where it comes to rest. If the scale is properly adjusted, the pointer will stop on the alignment mark to the right. If the scale is out of adjustment, it will come to rest a little above or below the mark (Figure 3-2).

To zero the balance, look for the small, chrome knob under the sample pan at the left end of the balance (Figure 3-3). This knob is actually a small weight, and screwing it in toward the center of the balance makes the pointer drop. Screwing it out away from the center makes the pointer rise. Using a process of trial and error, screw the knob in and out. tapping the pointer each time until it comes to rest on the alignment mark. When the pointer and the mark line up properly (Figure 3-4). the balance is ready to use.

Operating the Balance

When weighing powdered chemicals, you need something to put them in. An empty, plastic, soft margarine tub works fine, but you must always remember to subtract the weight of the tub from the scale reading to obtain the actual weight of the chemicals in the tub. For this reason, for future reference, you need to weigh the tub ahead of time, and write that weight on the tub with an indelible marking pen. The procedure for doing this goes as follows.

Figure 3-1. To zero a triple beam balance, first move the three sliding weights to their zero points.

Figure 3-2. If the balance is out of adjustment, the pointer at the end of the beam will come to rest either above or below the alignment mark.

Figure 3-3. Adjust the balance by screwing the small chrome knob under the sample pan in and out as required.

Figure 3-4. When the pointer comes to rest on the alignment mark, the balance is properly adjusted and ready to use.

Place the tub on the sample pan, and move the largest weight to the 100 gm. notch. This makes the pointer drop, so you know that the tub weighs less than 100 gms. Move the large weight back to 0. and try the same thing with the medium-size weight. Slide it a notch at a time to the right until the pointer drops again. In Figure 3-5 you can see that placing it at the 50 gm. notch first causes this to happen. This means that the tub weighs somewhere between 40 and 50 gms.

To find out exactly what the tub weighs, move the medium-size weight back to the 40 gm. notch. Then slide the smallest weight back and forth until the pointer comes to rest on the alignment mark. To calculate the weight of the tub, add up the readings from all three scales. In Figure 3-6 you can see that the reading on the 0 – 500 gm. scale is 0 gms. The reading on the 0 – 100 gm. scale is 40 gms.. and the reading on the 0 – 10 gm. scale is 4.7 gms. The tub in this example therefore weighs (0 + 40 + 4.7) = 44.7 gms.

Figure 3-5. Moving the medium size weight to the 40 gram notch has no effect, but moving it to the 50 gram notch makes the pointer drop, so you know that the tub weighs between 40 and 50 grams.

To weigh out a specific amount of chemical, place the tub on the sample pan. and set the sliding weights for the desired weight plus 44.7 gms. Then fill the tub with the chemical until the pointer comes to rest on the alignment mark.

Helpful Accessories

Ohaus sells an optional accessor}’ called a tare beam. It amounts to a fourth beam with its own sliding weight that you can move to the right or the left to compensate for the weight of the tub. When properly adjusted, you can dispense with the arithmetic, and make direct readings of your weight measurements. Another optional accessory is a sample scoop with its own carefully calibrated counterweight. You place the scoop on the sample pan. hang the counterweight on a peg at the right end of the balance, and the net result is the desired reading of zero. Forever thereafter, you use the scoop as the chemical container, and as with the tare beam, you can make direct measurements without having to account for the weight of the container.

The basic Ohaus balance weighs up to 610 gms. (about 1-1/3 lbs.). If you need to weigh more than 610 gms.. you can buy a set of attachment weights that hang on a second peg at the right end of the balance. With these added weights the capacity increases to 2610 gms. (about 5-3/4 lbs). My personal experience has been that, though I own a set of these weights, unless I am mixing a 1000 gm. batch of propellant. I don’t use them.

At the time of this writing a basic Ohaus triple beam balance {without accessories) costs about S125. If you go to the classified ads and the auction sites on the Internet, you can buy them second hand for much less.

Figure 3-6. To find the weight of the tub. add up the readings from each of the three sliding weight scales. In this case the answer is 44.7grams.

Reloading Scales

Reloading scales (Figure 3-7) are used by sportsmen to weigh out small amounts of rifle and pistol powder, and you can buy one at a gun shop or a sporting goods store. Reloading scales are inexpensive, but their capacity is limited to 100 gms. or less. This is alright if you are mixing 50 to 100 gram batches of propellant. but for anything more, reloading scales will not work. To weigh 500 gms.. you can weigh out five 100 gm. doses, but you’ll probably build up a cumulative error, and the error could be beyond the limits acceptable for your work. If you already own a reloading scale, go ahead and try it. If it doesn’t work, then buy something larger.

Other Scales

Other suitable scales are Harvard-Trip balances, and electronic digital scales (if they are accurate to 1/10 of a gram). The Harvard-Trip devices are mechanical like their triple beam cousins, but less convenient to use. They are primarily designed for comparing the weight of one thing to another. Without an accurate set of comparison weights, their capacity-is limited. For people on limited budgets. I’ve designed a homemade centigram balance that weighs up to 200 gms. with an accuracy of 1/100 of a gram. It is ten times as accurate as a triple beam balance, and it costs S15 to makeTFor a nominal fee you can download a complete set of plans from the Teleflite Corporation website at www.teleflite.com or www.amateur-rocketry.com. The electronic scales are the most convenient. The new ones are expensive, but like the triple beam balances there is a large market in used equipment. Electronic scales can be zeroed with the push of a button, and because you don’t have to wait for a beam to come to rest, you can work much faster than you can with a mechanical scale.

Scale Maintenance

All mechanical scales have to be serviced periodically to maintain their accuracy. If you don’t know how to do it. a scale dealer can do it for you. It usually involves disassembly, a cleaning of the scale’s critical parts, and a recalibration of the weights that make it work. Keep your scale indoors. Keep it clean, and keep it covered when you’re not using it. Treating it gently will minimize the need for service.