A key aspect of network maintenance and support involves cabling and rewiring. Although not the most glamorous aspect of maintenance and support, it is probably one of the most planning-intensive. When a new system or network is installed, invariably some wiring already exists and there is usually strong economic incentive for its continued use. When new wiring is installed, the desire to make it as useful as possible in subsequent feature and capacity expansions must be balanced against the initial installation cost.

Elements of Premises Wiring

There are typically several hierarchical layers of wiring that merit attention. With PBX installations, for example, these layers are:

■ The telephone carrier’s distribution frame or demarcation point, which is the termination of the carrier circuits on the premises and also the termination of carrier responsibility for the wiring. Often, this is simply a series of terminal blocks through which user CPE is attached to carrier circuits.

■ The incoming circuit distribution frame, a place where cross-connection between carrier lines and user CPE can be made. Cut-throughs or PBX bypass lines used to answer or originate calls when a PBX fails may be attached here, in front of the PBX. This is normally placed with the carrier’s demarcation point and may be omitted if there is only one CPE destination for all lines.

■ The user’s telephone equipment, linked to the incoming circuit distribution frame on one side and the private network or intermediate distribution frame on the other. The station pairs from the telephone system exit this equipment.

■ The intermediate private-network wiring distribution frame, where the telephone system station pairs are connected to terminal blocks or panels for matching with the building wiring.

■ Riser cables, which terminate in the intermediate distribution frame and link it to, for example, horizontal distribution panels on floors.

■ Horizontal distribution or wiring-closet panels that take riser connections and distribute them to the actual station wiring.

■ Outside wiring, serving the combined functions of riser cables and horizontal distribution cables where the run must exit the premises and transit an outdoor space.

■ Station wiring, which links the horizontal distribution panel with the instruments.

The wiring process is designed to achieve an important goal—permit restructuring of the system without actually stringing new wiring or performing extensive rewiring to accommodate moves, adds, and changes. Virtually the same considerations apply to hub-based LANs.

Cable Plant as Asset

In a properly designed wiring system, each cable pair should be viewed as a manageable asset, which can be manipulated to satisfy any user requirement. Individual cable pairs should be color-coded for easy identification, and cables should be identified at both ends by a permanent tag with serial numbers. This allows the individual pairs to be selected at either end with a high degree of reliability and connected to a patch panel or punch-down block as appropriate to implement moves, adds, or changes.

Patch panels and punch-down blocks should be designed to segregate different functions or circuit types to expedite the easy location of pairs. Data and voice connections, for example, can be terminated in different areas of the panel or block to avoid confusion. Many panels and blocks are precolored or have color-tagging capabilities, which can assist in locating pairs later.

The cabling used in wiring a telephone system or LAN depends on the requirements of the devices being used and the formal distribution plan provided by the telephone system and/or computer vendor Formal plans, such as IBM’s Cabling System or AT&T’s Premises Distribution System, compete with similar plans by nearly every major vendor All of these plans have the common goal of establishing a wiring strategy that will support present needs and future growth. In-house technicians should be familiar with these cabling schemes.

A number of asset management applications are available that keep track of the wiring associated with connectors, patch panels, and wiring hubs. These cable management products offer color maps and floor plans that illustrate the cabling infrastructure of one or more offices, floors, and buildings. Managers can create both logical and physical views of their facilities, and even view a complete data path simply by clicking on a connection.

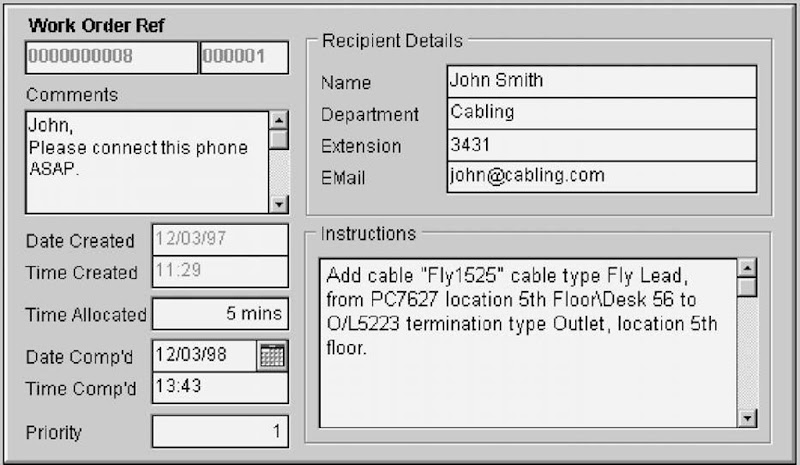

Some products provide complete descriptions of the cabling and connections, showing views of cross-connect cabling, network diagrams by floor, and patch panels and racks. Work orders can be generated for moving equipment or rewiring, and can include automatically generated instructions describing exactly what work must be done (Figure 13). With this information, network administrators know where the equipment should go, what needs to be disconnected, and what should be reconnected. Then technicians can take this job description to the location and make the necessary changes.

Other products provide a CAD interface, enabling equipment locations and cable runs to be tracked through punch-down blocks, multiconduc-tor cables, and cable trays. In addition, bill-of-materials reports can be produced for new and existing cable installations.

Cable management applications can be run as stand-alone systems or may be integrated with help-desk products, hub management systems, and network management platforms such as IBM’s NetView, Hewlett-Packard’s OpenView, and Sun’s Solstice SunNet Manager Some cable management products integrate well with all of these management platforms.

Figure 13

With the ETEC cable management system from Exan Technologies, every activity can be recorded and issued as a work order. A work order is created automatically, including the instructions, then users can add comments to amplify the instructions.

When coupled with a hub management system and help desk, a high degree of automation can be introduced to the problem resolution process. When the hub management system detects a media failure, the actual cable run can be extracted from the cable management application and submitted along with a trouble ticket generated by the help desk. And when the hub management system is integrated with a network management platform such as OpenView, all this activity can be monitored from a single management console, which expedites problem resolution.

Cable Planning

To determine if existing wiring can support new system installations requires a complete wiring plan, preferably prepared before the start of system installation. The plan acts not only as a guide to the installation process but as a check on the capacity and planning that can be carried out before installers appear and begin working. In the case of a PBX, for example, the plan should associate each instrument with a complete path back to the station wiring on the PBX, through all panels, horizontal feeds, and risers. During this process, the capacity of each trunk/riser should be checked one last time, and additional cabling run as needed. Spare pairs on each cable can be identified for possible future use.

As with station cabling, there are many factors to consider in deciding whether to purchase new or continue to use existing house cabling. The high cost of large-paired distribution cabling (300, 400, 600, or 900 pair) and its installation make the lease or purchase of existing cabling cost-effective. As with station cabling, the labor costs for identifying, retermi-nating, and documenting the existing cable remains. This cost increases as the number of pairs increase, as does the probability of an error. Because existing cabling often introduces unknown factors, such as pair counts, condition, and destination, many interconnect companies prefer to install new cabling. This cabling is much easier to document, install, and cutover because it is not being used.

A building under construction is the ideal environment for cable planning because it can be done according to the company’s needs without concern for the requirements of existing cable plant. Moreover, factors that hamper installation in an existing building are not present in a building under construction (i.e., cosmetic concerns, disruption of office personnel, and inaccessible areas). This allows attention to be focused on meeting the needs of each possible telephone instrument or terminal location.

Many companies specialize in cable installation, and may be contracted on a per-project basis through a bidding process. Some cabling contracting companies only install cabling; others both install and maintain cable networks. Because of the complexity of a cable network, it is convenient to deal with only a single company—one that endeavors to become familiar with the organization’s current and future cabling requirements.

If information systems and communications networks constitute a strategic resource to a company, so must its wiring. The proper planning for each wiring and rewiring of a facility can preserve these resources intact for the support of future applications. Improper wiring and poor record-keeping often leave no recourse but to fully rewire a facility—a task that is often far more expensive than new installation. See Also Cable Testing, Physical Network Management