6.4

The essential equipment for measurement by light wave interference is a

monochromatic light source and a set of optical flats. An optical flat is a circular piece of optical

glass or fused quartz having its two plane

faces flat and parallel and the surfaces

are finished to an optical degree of flat-

ness. Optical flats vary in size from 25

mm diameter to about 300 mm diameter.

Quartz flats have high wearing qualities

and have 200 to 400 per cent great wear-

ing qualities than the optical glass.

Quartz has minimum expansion due to

heat and the thickness used insures

freedom from distortion in use. The im-

portance of optical flats is apparent in

lightwave measurement because all in-

spection operations are performed with

reference to the master surfaces of the

optical flats. (For more details about

optical flats, refer Art. 6.10).

If an optical flat is placed upon another flat reflecting surface (without pressure) it will

not form an intimate contact, but will lie at some angle 0 making an inclined plane. If the

optical flat be now illuminated by monochromatic source of light, the eye if placed in proper

position, will observe a number of bands. These are produced by the interference of the light

rays reflected from the lower surface of the top flat and the top surface of the lower flat through

the very thin layer of air between the flats. In Fig. 6.5, the angle 6 between the two flats is

shown exaggerated too much. S is the source of monochromatic light. At point A, the wave of

incident beam from S is partially reflected along AB and is partially transmitted across the

air gap along AC. At C, again the ray is reflected along CD and passes out towards the eye

along CDE. Thus the two reflected components, reflected at A and C are collected and

recombined by the eye, having travelled paths whose lengths differ by an amount ACD.

Fig. 6.5. Flatness testing by interferometry.

If the path lengths of the two components differ by an odd number of half wavelengths,

then condition for complete interference is achieved. If the surface is perfectly flat, then

condition of complete interference is satisfied in a straight line across the surface as the surface

at right-angles to the plane of the paper is parallel to the optical flat. Therefore, a straight

dark line will be seen passing through point C. Consider another ray incident along path SFH.

Again this ray is also splitted into two components. It is obvious that the path difference of the

two component rays will keep on increasing along the surface due to angle 9. Thus if the path

difference FHI be 3X12 or the next odd number of half wavelengths, then interference will occur

and a similar fringe will be seen. Next when path difference is 5K/2, again there will be another

dark fringe. At the intermediate point between the points C and H, the path difference will be

an even number of half wavelengths and the two components will be in phase producing a light

band.

Thus, in case of a perfectly flat surface, we will have pattern of alternate light and dark

straight lines on the surface, as shown in Fig. 6.6. Any deviation from this pattern will be a

measure of the error in the flatness of the surface being inspected.

6.4.1. Checking the Flatness by above Method. Referring again to Fig. 6.5, if 0 is

very small, (which is generally the case, as it is made due to some particles between optical

Fig. 6.6. Interference pattern on

perfectly flat surface.

Thus it is obvious that each adjacent fringe represents a change in elevation of the work

surface relative to the optical flat of X/2 and total change in elevation from point of contact to

the outermost fringe will be n x X/2, if it contains n number of adjacent fringes.

Now there are four possible cases when the contact between the optical flat and the work

surface occurs at one point only.

(i) If the surfaces are perfectly wrung together, then no air gap exists and no fringe

pattern will be observable.

(ii) If angle 0 is increased, then points C and H will be closer together and fringes are

brought closer together.

(iii) If angle 0 is reduced, then fringes spacing increases as the points C and H will occur

at greater distances.

(iv) If 0 is made too large, then fringes will be closely spaced as to be indistinguishable

and no observable pattern will be visible.

The viewing angle, i.e. the angle at which the bands are viewed should be 0°, i.e. line of

sight should be perpendicular to the reference surface of the optical flat. If viewing angle is

30°, then 3 fringes may be seen as 2.5, causing an error of nearly 15%. If it is 45°, 3 fringes

may be read as 1.75, causing error of nearly 40%.

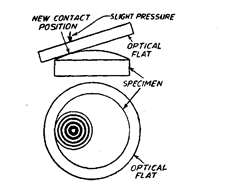

In practice, on the surface to be tested,we have large number of hills and valleys and in

these circumstances it is impossible that contact between the surface and the optical flat will

occur at one point only. Rather the contact will be made at a large number of hills. If the optical

flat is resting on any hill, then it will just behave as if it were placed on some spherically convex

surface. In such a case, the contact is made at the central high point and in centre a bright

circle will be visible. Around it, there will be concentric dark and bright circular fringes. As

the distance from the centre increases, the separation between optical flat and surface keeps

on increasing and the fringes become narrow and more closely spaced as shown in Fig. 6.7.

Fig. 6.7. Fringe pattern as observed

through optical flat.

Fig. 6.8. Test for convex surface.

For testing any flat surface, we have to lower down the level of hills. Actually by naked

eye, one can’t differentiate between the hill and valley in case of fine finished surfaces. And

the fringe pattern obtained by concave surface will be same as in case of convex surface.

To distinguish between the two conditions of convex and concave surfaces one edge of

the optical flat is lightly pressed. In case of convex surface, by light pressure the optical flat

will rock on a new high spot and the centre of the fringe pattern will move as shown in Fig.

6.8. Also the outer fringes will move closer together.

In case of spherically concave surface, the flat is resting on a line passing around the

surface and on lightly pressing the edge of the optical flat, the edge line does not move as the

pressure is varied. Rather, light pressure at the centre will cause the optical flat to be deflected

and will become more nearly parallel to the concave surface, thus reducing the number of

fringes observed.

Thus if by light pressure, the centre of fringes is displaced and the fringes are brought

closer, it is convex (hill) surface and the level at that place must be lowered down to form a flat

surface. If by light pressure the number of fringes is reduced and the fringes move apart, it is

(valley) concave surface.

Sometimes surface might not be perfectly convex or concave. So the study of various

patterns of fringes produced for different types of surfaces is very essential.

Interferometry Applied to Flatness Testing (Metrology)

Next post: Surface Contour Test (Metrology)

Previous post: Light Sources for Interferometry (Metrology)