Abstract

Building automation systems and metering systems are an enormous source of valuable operational data. However, it is rarely put to use, as facilities professionals do not have adequate means to collect and manage the data. The information is lost and decisions are made without solid operational facts, resulting in underperforming buildings and physical plants. An Enterprise Energy Management System (EEMS) addresses this by collecting all of the operational data from building systems, organizing it, and providing users with highly interactive access to the infomation contained within the raw data.

This article highlights the key functional requirements of an EEMS, and focuses on the complexities of collecting data from the many disparate sources and making it a highly valuable information source for operators, engineers, technicians, and management.

INTRODUCTION

It is all about the data. Current building automation systems (BAS) and metering systems produce huge amounts of valuable data—most of which is thrown away. Facilities staff and engineers typically use as little as 1% of the available data for making decisions about operations, building and plant optimization, commissioning, design engineering, performance contracting, automated diagnostics, and other related tasks. This is the fundamental role of an enterprise energy management system (EEMS)— to collect all of the available data related to energy consumption and costs, organize it, and provide users with access to the engineering facts that live within the data.

Unlike control systems and diagnostic tools, an EEMS provides a complete view of an entire facility’s operations, not just component parts. This level of insight is the only way to achieve all of the business benefits possible, including lower energy consumption, improved space comfort, extended equipment life, better use of staff, energy purchase savings, demand reduction, better engineering designs, lower construction costs, and much more.

This entry highlights the key functional requirements of an EEMS and focuses on the complexities of collecting data from the many disparate sources, making it a highly valuable information source for operators, engineers, technicians, and management.

EEMS Defined

An EEMS consolidates energy-related data (sources, costs, and control and monitoring points) into a data warehouse and provides a platform for tools to access the data easily and obtain actionable information.

The EEMS makes data-driven information available so that the end user is able to perform in-depth diagnostics, engineering analysis, and monitoring in a small fraction of the time it took with earlier methods. By publishing information for consumption outside the traditional facilities management area, an EEMS supplies critical information to department heads, financial staff, and executive management as well.

Five simple but crucial principles form the basis of an ideal EEMS:

1. All energy-related data is consolidated into a centralized data warehouse.

2. The collected data is “normalized” and structured.

3. Access to data is interactive to facilitate distillation of actionable information.

4. The system makes it easy to measure and verify results.

5. The system provides a platform that embraces industry standards for data collection, management, analysis, and publication.1-1-1

It is worth noting what an EEMS is not: it is not a control system, and it should not be confused with a BAS. An EEMS is much broader in scope. It provides a platform for data collection, data access, diagnostic and monitoring capabilities, a historical data warehouse, and a lot more, as detailed throughout this entry. Similarly, an EEMS is not a utility billing system. It encompasses billing and meter data but extends beyond by connecting billing information directly to the related operational data.

EEMS PRINCIPLE 1: CONSOLIDATE ALL ENERGY-RELATED DATA INTO A DATA WAREHOUSE

Energy-related data comes from purchased utilities, generated utilities, BAS, metering systems (both advanced and manually read), weather, computerized maintenance management systems (CMMS), and space planning systems. Additionally, an EEMS manages rate and billing data, users, and organizational information.

To be able to utilize energy data, the first step is to identify and collect the right data into a data warehouse so that accurate and actionable information can be available. The EEMS needs to collect all data, as one cannot optimize the whole system by optimizing each component.

This section identifies the different data sources and attributes that define an EEMS and populate its data warehouse.

Purchased Utilities

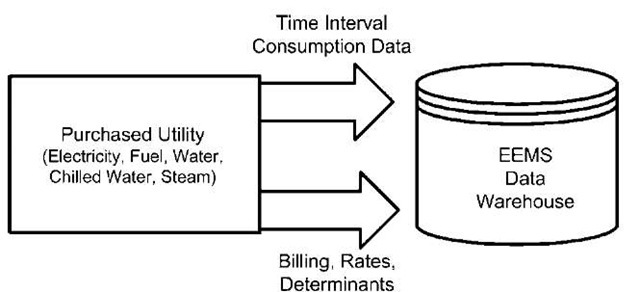

Most facilities purchase electricity, fuel (usually natural gas or oil), and water. Some also buy chilled water and steam. An EEMS manages both consumption and billing information, and presents this data in an intelligible, clear, and actionable format. Fig. 1 is a simplified view of the issues related to collecting utility data.

Consumption information is typically time based, regardless of the type of utility. For example, electric utilities commonly use 15-min intervals; natural-gas utilities use daily intervals; and water uses monthly or quarterly intervals. Eventually, these different time series need to be “normalized” so that information can be presented in consistent intervals.

Billing information is equally complex. Large facilities often have multiple vendors for each utility type, each with differing rates, billing cycles, and pricing

Fig. 1 Billing and consumption data should be collected in tandem.

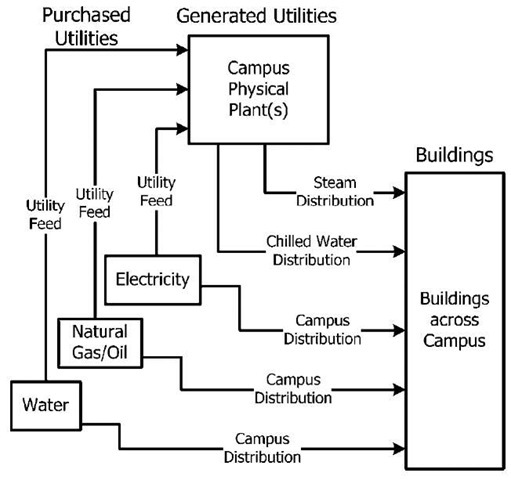

Fig. 2 Institutions typically deliver purchased and generated utilities to the facility.

structures, resulting in a significant amount of billing data to collect and manage. For example, a university may have 1000-10,000 utility bills per year.

Generated Utilities

Most large facilities have their own physical plants that generate and distribute chilled water and steam. An EEMS collects data from the control system(s) of the plant, as well as from the distribution network and buildings (Fig. 2).

The EEMS also collects billing information, just as it does for purchased utilities. Facilities that generate their own chilled water, steam, or even electricity will have their own rate structures and determinants, and they will bill internally based on consumption.

Building Automation Systems

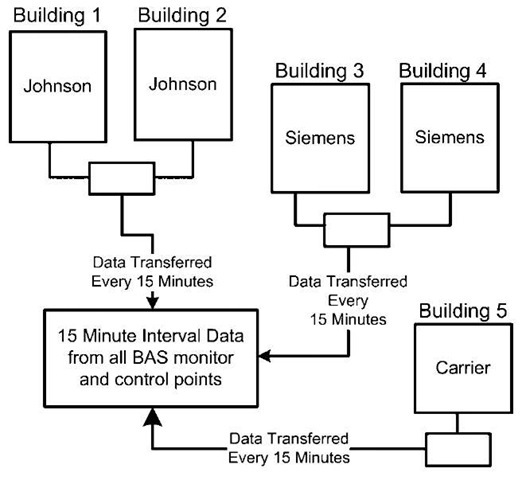

Many institutions operate more than one BAS, so an EEMS provides a complete, holistic view by collecting data from all systems and overcoming the limitations of relying on the BAS for data. It is this systemwide view that enables organizations to diagnose operations and energy usage more quickly and effectively (Fig. 3).

Extracting Data from the BAS

To provide a comprehensive picture, an EEMS requires data from all control and monitoring points. Gathering data only from monitoring points (without control data) means that while you may identify something to improve, it is unlikely that you’ll gather sufficient information to know with certainty how to improve it (Fig. 4). (This is what happens when one installs advanced metering systems instead of an EEMS.)

Fig. 3 Energy management system (EEMS) collecting data from multiple building automation systems (BAS).

At large facilities, it is not unusual to have 30,000130,000 points (or more), each generating one value every 15 min. For every 30,000 points, there are over a billion data intervals per year. Without an EEMS, much, if not all, of this information is thrown away (Fig. 5).

Meters and Metering Systems

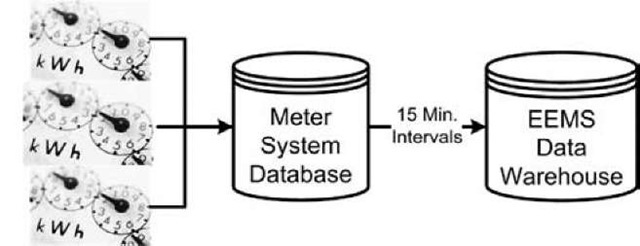

Meters and metering systems are typically located at buildings and throughout the distribution system to measure the use of electricity, steam, chilled water, fuel, etc. (Fig. 6).

For electricity, access to metering data via the metering database is a relatively straightforward process, but for those utilities that do not leverage advanced metering systems, data can be obtained through the BAS (Fig. 7).

Fig. 4 The energy management system (EEMS) collects various kinds of data from control and monitoring points every 15 min.

In addition to the automated data collection described above, an EEMS will incorporate manually collected data.

Other Data Sources

Weather has a large impact on energy consumption and forecasting. For the most accurate results, an EEMS includes official weather data from a local airport, in addition to local sensors that may be inaccurate for various reasons, such as being located too close to a building, in the sun, broken, etc. (Fig. 8).

Space planning data is used by an EEMS to identify energy costs at the space level. Space planning systems contain information concerning the use and allocation of all areas within a facility. They map the hierarchy of the facility and understand the relationships between space and cost centers.

Market and pricing data affects the ability to purchase energy at favorable rates. Prices, pricing structures, and regulations constantly change. The role of the EEMS in purchasing energy is threefold:

• To display past and future energy usage patterns

• To convert and present utility billing and consumption usage into an equivalent real-time price

• To present real-time pricing information.

Easy access to actual and predicted usage patterns enables the organization to make more-informed utility purchasing decisions than ever before.

Do Not Throw Data Away

Large organizations spend millions of dollars annually on energy, millions on systems like BAS, and tens of millions for heating, ventilation, and air conditioning equipment, yet they throw away most of the data these systems generate, largely because there is so much data, and they are difficult to access, manipulate, and interpret.

An EEMS captures these data and leverages them to provide a complete picture of utility consumption and an organization’s energy infrastructure over time so that the most expeditious analysis can take place to reduce the total cost of ownership and operation.

EEMS PRINCIPLE 2: NORMALIZE AND STRUCTURE DATA

Energy management system (EEMS) Principle 1 focuses on the importance and requirements of getting data into the system. Principle 2 addresses constructing a data warehouse based upon the data least common denominator: a standard time interval.

Fig. 5 The ability of an energy management system (EEMS) to store, manipulate, and display very large volumes of data in an efficient manner is mission critical.

Optimal Time Interval

An EEMS uses a standard time series interval, selected to ensure sufficient data to identify transitions. This means that there should be enough data points gathered to discern performance fluctuations across transition time periods (between day and night, office hours and nonworking hours, etc.) so that behavior patterns and problems become apparent quickly.

For this reason, and because electricity is frequently metered within the same time interval, 15 minutes is an appropriate time for EEMS normalization. Longer intervals do not provide sufficient data granularity to show all behavioral changes. Shorter intervals can be used, but one has to manage the trade-off between more data and more information. You also need to consider how long data will be kept—ideally, for the lifetime of a piece of equipment (20 years or more).

Normalized Interval Data

Normalizing means that data from all sources is stored in the warehouse in the same time interval. Not all data sources provide data in the same interval, so the EEMS reconciles these differences.

Interval data inconsistencies are a fact that must be acknowledged and addressed. A well-implemented EEMS accepts these inconsistencies and fills the gaps with estimates that, when totaled, account for the total energy consumed and represent the pattern of that energy usage in a precise and accurate manner. For meter data, the relevant utilities’ processes for validating, editing, and estimating (VEE) should be followed.

Fig. 6 A connection between the metering databases and energy management system (EEMS) must exist to synchronize data views of meter and building automation systems (BAS) data.

Data Warehouse Structure and Hierarchy

To derive value from such a large amount of data, a defined structure and hierarchy must exist to make the data readily consumable. The EEMS data structure requires flexibility too, because physical configurations are constantly changing—buildings are added, equipment fails unexpectedly, organizational changes lead to space modification, etc.

Warehouse Objects

The data structures in an EEMS parallel the physical facility, allowing it to be easily used to focus on an individual building or piece of equipment.

An EEMS warehouse supports logical objects—sets of information and relationship hierarchies—that allow for this structure. Table 1 shows six such warehouse objects and the hierarchy that exists within them. The warehouse structure also supports the way different elements within the object inter-relate—for example, the way meter interval data connect to billing rate data and physical building data.

EEMS PRINCIPLE 3: PROVIDE INTERACTIVE ACCESS TO ACTIONABLE INFORMATION

Defining Interactive and Actionable

Interactive access allows the users to work with the data in a dynamic fashion, moving seamlessly through the data with tools that provide near-instantaneous response. This allows users to “work the way they think” rather than being limited to a series of static queries and reports.

Actionable information is usable as the basis and rationale for effective decision-making. To create actionable data, the EEMS should collect both monitoring and control points. With monitoring data alone (without control information), it is difficult to verify or quantify the savings opportunity.

Fig. 7 Data can be obtained and transferred through a building automation systems (BAS).

Fig. 8 METAR weather data should be used within an energy management system (EEMS).

Table 1 Object hierarchies maintained by an energy management system (EEMS) data warehouse

Facility objects Site Zones Buildings Floors Rooms

Higher education general information survey (HEGIS) group HEGIS classification Issue objects

Issues Organizational objects

Departments User objects User privileges Users

Interval data collection objects

Building automation systems (BAS) and OLE for process control (OPC) point data

Calculations

Balance efficiency calculation

Cooling efficiency

Cost calculations

Delta T

Theoretical water loss Etc. Weather data Meter objects Utility type

Utility information Account information Meter information Rate information Billing information

Time and Usability Matters

With gigabytes or even terabytes of data to manage, the use and operation of an EEMS cannot be an arduous and time-consuming task. An EEMS accesses and presents data to users at the “speed of thought,” enabling users to view information created from hundreds of thousands of data intervals in a few minutes. If users have to wait for this information, their thoughts will wander. If they continually have to wait, and if they are not constantly engaged, their reaction will be that the EEMS is wasting their time.

Currently, most facility personnel waste an enormous amount of time collecting and distributing data. This wasted time is culturally accepted as part of the job, when in fact, instead of spending days manually gathering and piecing together data, a well-implemented EEMS can deliver it in seconds. With immediate access to the data and information, staff frees up time to devote to the real engineering work of diagnostics, analysis, and planning.

The time required to gain insight is directly related to the usability of the system. It is essential that data can be assembled dynamically by the user via a simple, intuitive interface. The elements of the interface include the data organization and visualization, and the program interface itself. A well-integrated EEMS supports other aspects of the facility staff’s workflow, such as tracking identified issues or interacting with external analysis tools.

Data Organization and Presentation

An EEMS categorizes data in meaningful ways, such as organizing within the facility hierarchy (zones, buildings, floors, rooms), organization (departments, rooms), or systems (chiller system, air handling system). In most cases, data access occurs through multiple views so that, for example, a building manager can examine the building information while a plant engineer can look at chiller operations facility-wide. Users can “drive through the facility” from their desktops by viewing the information. An EEMS also provides a method for users to define their own organized views.

The Importance of Trend Data

Trend data is the foundation of diagnostics, monitoring, measurement, and verification, and building a historical record of facility operations. While BAS typically contain a function called trend logs, they are a poor mechanism to collect trend data for the EEMS due to a variety of limitations. Trend lines from the EEMS interval data provide a data visualization and interaction paradigm that does not suffer these same limitations (see Table 2). The differences elevate, by orders of magnitude, the effectiveness of an EEMS for diagnostics, monitoring, and other applications, which results in actionable information.

Table 2 Some of the uses, users, and differences between building automation systems (BAS) trend logs and energy management system (EEMS) trend lines

| Application of BAS trend logs and EEMS trend lines | ||

| Criteria | BAS trend logs | EEMS trend lines |

| When to use | ||

| Diagnosing operations | After problem has been identified as under the control of the BAS and further data is needed for final diagnosis | Always—superior tool for nearly all diagnostics and all cases where historical data or data outside the BAS must be considered |

| Monitoring operations | When real-time data for a small number of BAS points needs to be watched | Always—provides the ability to monitor hundreds of trends in minutes, combining data from any and all sources |

| Typically used by | BAS control engineers and technicians | BAS control engineers and technicians, energy engineers, area mechanics, facility managers, performance monitoring contractors, commissioning agents, HVAC design engineers |

| Technology perspective | ||

| Data storage | Stores point data for trends defined | Stores data for all points from all systems |

| Data availability | Only those points explicitly trended, with the total number of trends extremely limited (a few points) | Historical trend data always available for every point in the system (many thousands) without affecting control system performance |

| Time interval of data | Captures data in increments from milliseconds to minutes | Captures data from all systems at regular intervals (e.g., 15 min) |

| Displays data from | Native BAS | Multiple BASs, metering systems, utilities, weather, billing |

| Display time period | Typically a few days or weeks | Between a day and a year, with historical data going back years |

| Data storage | Up to a few months and data is discarded | Up to 20 years |

Building automation systems trend logs do have their place in providing needed information—where their ability to collect real-time data is useful—as shown in Table 2.

Calculated Data: Providing Actionable Information

The efficiency gains in having commonly desired calculations available for monitoring and diagnostics are tremendous, and they have a dramatic impact on usability. A visual display of an ongoing trend built on a calculation can provide insight instantly that would otherwise take hours of analysis in Microsoft Excel.

More complicated calculations can provide users an overall operational efficiency rating, the power consumptions, and the energy cost for each 15-min period. Calculations of this complexity rely on the EEMS’s ability to integrate fully data from all sources and present them in a normalized fashion as actionable information. A sample of calculations includes

• Balance equations

• Chiller efficiency

• Chiller total cost

• Chiller plant total hourly cost of operations

• Cooling tower cost and efficiency

• Cooling tower makeup water cost and efficiency

• Delta T

• Pump brake horsepower

• Pump efficiency

• Pump kW

• Theoretical water loss

• Tons output.

Application Interface

All the usability factors mentioned must come together in the software user interface. It is how end users interact with the data—through mouse clicks, menu selections, expandable data trees, contextual menus, dragging and dropping, etc.

The EEMS allows users to take an iterative approach with each action, building on the last for diagnostic purposes. Monitoring is fast and efficient, allowing users to cycle quickly through hundreds of trend lines in minutes. Ultimately, it is the combination of information display (trend lines, calculations, etc.), user interface, and system performance of the EEMS that allows the user to work at the speed of thought and to improve the quantity and quality of decisions made.

Present User-Specific Information

An EEMS supports a variety of energy-related applications and users, including energy engineers, HVAC design engineers, technicians, area/building mechanics, facilities engineers and managers, commissioning agents, energy purchasers, and performance contractors.

An EEMS provides a variety of output options that enable everything from detailed reports with data tables and charts of multiple trend lines to summary reports that roll up information into cost breakdowns and overall operating-efficiency ratings.

Users of information from an EEMS extend well beyond facilities and maintenance staff to building managers, department heads, finance personnel, executives, and managers—anyone who has occasional needs for some facilities information. These “tier two” users typically do not need interactive access to the data at the individual point level and are well served by predefined reports focused on business issues, not engineering details. Enterprise-level energy and operational data published to meet their specific needs and interests will help realize the many business benefits listed later in this entry.

EEMS PRINCIPLE 4: MEASURE AND VERIFY RESULTS

All too often, performance measurement and verification (M&V) ends up neither measuring nor verifying performance. It is a simple case of not having access to the data to do M&V properly—a problem an EEMS solves. Without an EEMS, verifying and measuring results of optimization efforts are largely left to engineering estimates and educated guesswork. At the very least, it is an extremely time-consuming process to gather thorough operational data. The ability to quantify improvements accurately and monitor their persistence gives facility directors the tools to hold contractors and their own staff accountable, and these tools can help directors increase their credibility with upper management.

In measuring and verifying results, it is important to define terms often used to justify and quantify the impact of investments in utility operations.

Energy Savings vs Dollar Savings

An EEMS accounts for both energy savings and cost savings (actual dollars). Just because the utility bill dropped does not necessarily indicate that money/energy has been saved; rather, it confirms only that less money was spent. It verifies nothing about reduced energy consumption.

Factors like price, weather, new construction coming online, and consumption rates are required to understand whether actual energy savings have occurred. To realize true energy savings, which in turn lead to dollar savings, consumption must be reduced independent of these factors, and this can be achieved only when energy usage is being controlled more efficiently.

Stipulated Savings vs Real Savings

Stipulated savings typically are savings amounts specified and agreed to up front with an entity assisting with funding energy efficiency improvements—for example, a performance contract for retrofitting lighting that uses 25% fewer watts or replacing an older chiller with a newer, more efficient model. Stipulated savings often do not translate into real savings because more variables than just the efficiency of the equipment come into play.

The stipulated amount will not take into account issues such as the percentage of lighting fixtures that aren’t working prior to the retrofit, or behavioral changes in hours the new lighting is in use or the percentage of lights turned on, and often, this amount will not consider the additional heating energy required during winter months because of the lower wattages. This isn’t to say that the efficiency gains promised don’t exist, but that one may not see the expected consumption reductions in utility bills. An EEMS allows one to view both the data for the electricity consumed by equipment type and for the utility consumed to heat (or cool) the area, all within the context of a specific space, allowing a real savings assessment to be made.

Use Life-Cycle Costing

An important concept to adopt is life-cycle costing. It is the most appropriate way to assess equipment and building costs. The initial purchase of HVAC equipment is a significant capital investment, but its true costs lie in this number plus the cost of its operation, service, maintenance, and total life span.

EEMS PRINCIPLE 5: A PLATFORM THAT EMBRACES INDUSTRY STANDARDS

Using industry standards and an open architecture is the right way to build any enterprise-class application. This has been proved repeatedly at all levels of technology and business, where broad support and interoperability are significant benefits. A platform architecture and the use of standards protect the organization by minimizing dependency on any single vendor, even allowing functionality to be added outside the vendor’s development cycle.

There are standards in several areas that an EEMS should adhere to.

Operating system. There are three platforms, sufficiently open and standardized, that an EEMS could run on. The first, and by far the most popular, is Microsoft Windows. It offers the greatest availability of tools and options, and is already installed and supported nearly everywhere. The Microsoft.NET platform is excellent for developing and integrating application components. Other options include Linux, which has strong server support and tools such as J2EE but is a limited end-user platform, and a Web-based solution, which involves Windows or Linux servers using Web browsers for the application front end (which instills limitations on the user interface).

Database management. Data storage for an EEMS should be open, accessible, and interoperable with other systems using a standard relational database (e.g., SQL Server, Oracle, etc.). Proprietary data managers will handcuff users to rely on the vendor for everything.

Data collection. As discussed earlier, data are the lifeblood of an EEMS, and access to these data is a complex and arduous task. Standards such as OLE for process control (OPC), BACnet, and LonWorks enable cost-efficient solutions for data collection.

Analysis. Data analysis tools range from the most general and broadly available (Excel) to highly specialized analytics. Ideally, the EEMS will provide direct support for Excel, allowing users to take advantage of analysis routines already developed. Minimally, the EEMS will provide data export into any analysis program.

Space planning and classification. For colleges and universities, the EEMS should support higher education general information survey (HEGIS) groups and classifications for space planning. It should also interface with market-leading space planning systems.

Publishing. Making information available throughout the organization requires a standard format, such as HTML. For long or data-intensive publishing, other formats may be appropriate, such as PDF, XML, or Microsoft Office.

Geographically Dispersed Enterprises

Not all enterprises are located in a single building or campus. When implementing an EEMS across a series of locations, it is preferable to collect data locally at each facility, primarily to minimize the number of possible points of failure that could interrupt data collection. A well-architected EEMS will allow centralized users to view and combine data from the individual locations, thereby still realizing the full benefits of an enterprise wide understanding of operations.

The size of the individual facilities may influence the local/central decision. For example, a school district may choose to deploy an EEMS centrally because the engineering and operations staff may be a single, district-wide group. However, local technicians and mechanical staff should have access to the data pertaining to their school.

BUSINESS APPLICATIONS OF AN EEMS

The EEMS has many business applications, each with different benefits to the facility. Some of these applications deliver benefits that are operational savings (reduced energy consumption); some enhance the infrastructure; and others address the business of facilities operations. The most common applications of an EEMS are:

• Operational diagnostics and monitoring

• Efficient building control strategies

• Building and physical plant commissioning (existing buildings and new construction)

• Validating engineering design/redesign and construction

• Chiller plant efficiency calculations

• Controlling building comfort

• Enhanced customer service

• Accurate energy cost allocation

• Capital-request justification

• Information publishing

• More accurate budgeting and forecasting

• Increased accountability and credibility

• Purchased utility accounting

• Vastly improved performance M&V.[2]

Financial Benefits of EEMS

It is clear that an EEMS is able to provide the infrastructure to support many different business purposes. It is important that these applications of EEMS technology are also able to deliver a rapid return on investment in a number of areas, including:

• Lower operational costs

• Positive cash flow

• More effective staff deployment

• Greater indirect cost recovery

• Reduction in equipment maintenance costs and increased equipment life

• Improved efficiency of energy purchasing.

CONCLUSIONS

This entry provides the reader a definition, a functional description, and insight into the complexities of an EEMS. For readers considering an EEMS purchase, this entry does not address in detail issues such as the functionality/value/cost relationships. Larger facilities— those with a million square feet of space or more—should look for an EEMS that is complete and meets the ideal criteria. At this writing (2006), these systems have not scaled down in size sufficiently to necessarily be cost effective for smaller facilities. This will happen over time, especially as BAS vendors make data more easily available.

An ideal EEMS will adhere to the following criteria:

• It collects data from all monitoring and control points from all sources, gathering consumption data, control settings, and billing and rate information to provide a holistic view.

• It normalizes and structures the data within a data warehouse, providing flexibility to handle complex relationships, hierarchies, calculations, and adjustments to meet evolving requirements.

• It presents actionable information through trend lines and other reporting/graphical formats. Performance and user interface must combine to provide interactive access to the data.

• It delivers value and savings that can be measured and verified.

• It is more than an application—it is a platform for energy management and other facilities operations that is expandable and conforms to open standards.

An effectively implemented EEMS provides unparalleled insight into facility operations. It nearly eliminates the time wasted by staff gathering needed data. It provides individuals the ability to find and address inefficiencies rapidly (fixing the root cause, not just treating symptoms) that can result in immediate cost savings and an ongoing financial return—often when these problems have gone undetected for many months or even years.

An EEMS presents the opportunity to span all existing BAS and energy-related data so that assessments can be made in the context of the whole facility, environment, and billing climate. Complete information leads to better decisions—decisions that address building comfort, energy consumption, operational costs, capital investments, and stewardship of the assets.