8.2.4

A method of linear approximation to determine torque current and heating may be used in many cases.The example that is shown next may be modified to meet any particular problem. Note that it does not take thermal capacitance into account. In some situations thermal capacitance may be significant. See Sec. 8.4 for a method that does account for thermal capacitance.

Define a varying load and determine its effect on the heating of the motor. Assume the load and velocity parameters specified here. Refer to the velocity profile shown in Fig. 8.3.

Using motor parameters from available data:

FIGURE 8.3 Velocity profile.

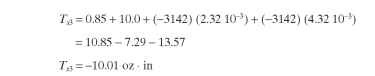

Calculate the required torque for each section of the velocity profile. For section 1, the torque to accelerate must be included.

This just means that the power supply must produce 10.01 oz • in of torque in the other direction to get the motor to stop in the required time.

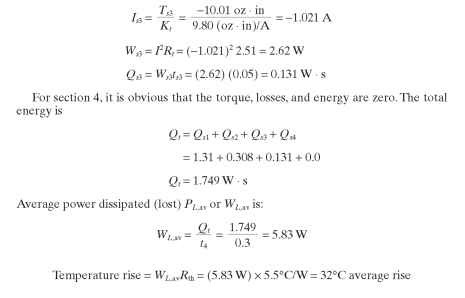

Is this a good choice of motor? Assume that the motor has Class B insulation. Then the maximum operating temperature of the copper wire is 130°C. Assume there is a hot spot inside the copper windings that is 10°C hotter than the outside of the windings, just to be safe. Now the maximum temperature becomes 130°C – 10°C = 120°C. If the ambient temperature of the device is 40°C, then you are allowed a maximum temperature rise of 120°C – 40°C = 80°C. You calculated a 32°C rise under your load profile. You could run the motor 48°C hotter. Therefore, you have chosen more motor than you need. Select a smaller motor.

Deceleration—Plugging Step Voltage (Reversal of Voltage Polarity) (Electric Motors)

Next post: CURRENT DENSITY (Electric Motors)

Previous post: MOTOR APPLICATION REQUIREMENTS (Electric Motors)