Abstract

Automatic lighting controls have become a standard feature in new construction due to prevailing energy codes. Advancements in technology now enable a broad range of globalized and local, automatic and manual control strategies to generate energy savings and support visual needs.

INTRODUCTION

Lighting controls are an essential part of every lighting system. The most basic example of a lighting control is the common switch. When the switch is flipped on, the circuit is closed, enabling the flow of current to operate the connected lighting system.

A wide variety of devices and systems are used to control lighting systems in commercial and industrial buildings. Of particular interest is lighting automation, which presently represents a major frontier in building and energy management. Automated lighting controls automatically switch or dim lighting systems based on a given input. The automation of this functionality can provide significant benefits.

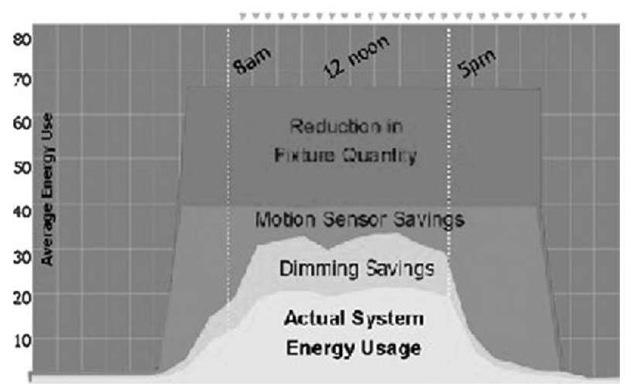

In some industries, lighting accounts for more than 60% of a facility’s electrical bill and 40% of the total energy bill. Automated lighting controls can contribute significantly to operating cost savings by switching or dimming the lights according to time of day, whether the space is occupied, amount of available daylight, current level of light output from the lamp, and other factors. According to the New Buildings Institute, which developed the 2001 Advanced Lighting Guidelines, automatic lighting controls can reduce lighting energy consumption by 50% in existing buildings and at least 35% in new construction. Related to a reduction in energy consumption are load shedding and peak demand reduction, which can reduce demand charges imposed by the utility (Fig. 1).

In addition, lighting automation can provide mood setting, via the ability to alter a space through dimming or color changing; flexibility, by allowing users to instantly adapt a space to different uses; the ability to establish a responsive lighting system that can be globally and locally controlled with automatic operation; the ability to adapt electric lighting systems to daylighting strategies; enhanced security; decreased “light pollution” (skyglow, light trespass, and glare), by dimming or switching outdoor lights based on time of night or occupancy; enhancement of workspaces with a technology that has visible effects; and potential increased worker satisfaction, by enabling users to control their own light levels. The list goes on.

Lighting automation can be completely automated or can contain elements of manual operation; it can be localized, global or both; it can be hardwired or wireless; and it can be used for switching or dimming. A wide variety of proven and developing technologies is now available to achieve a wide variety of building and energy management goals (Table 1).

COMMON STRATEGIES

Lighting controls can perform one or more of seven basic functions: on/off, occupancy recognition, scheduling, task tuning, daylight harvesting, lumen depreciation compensation, and demand control.

On/Off is the basic control function, achieved through switching.

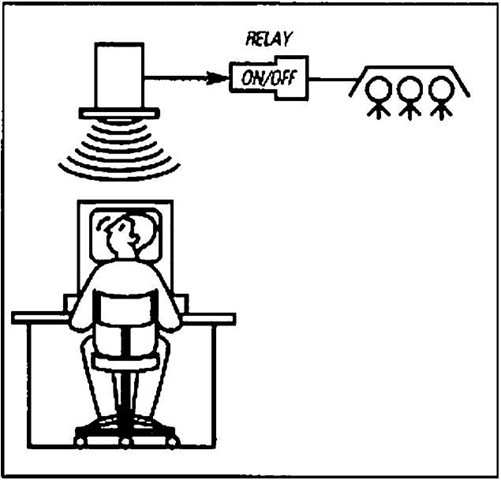

Occupancy recognition is used in intermittently occupied areas, typically to turn lights on automatically when the area becomes occupied and off when it becomes unoccupied. Some occupancy recognition devices are manual-on, automatic-off. The occupancy sensor technology is typically ultrasonic (sensing changes in transmitted sound waves returning to the device), passive infrared (sensing changes in heat in the area), or a combination of the two.

Scheduling is used for areas of predictable occupancy, in which a control system dims, activates or shuts off a lighting system on a predetermined schedule. Local manual overrides are usually provided. A typical weekday lighting schedule is shown in Fig. 3.

Tuning entails adjusting the light output of a lighting system to a desired level needed for a task or other purpose, such as aesthetics or mood setting. This can be achieved through either dimming or switching layers of lighting (such as bi-level switching, in which half of a lighting system is shut off in a space while the other half continues operating).

Fig. 1 A complete lighting upgrade can save energy on multiple levels, including fixed load reduction through reduced fixtures or lower-wattage lamp ballast systems, and variable load reduction through strategies such as occupancy recognition, scheduling and personal dimming.

Daylight harvesting is used to enable lighting systems to respond to ample available daylight by dimming or some level of switching.

Lumen depreciation compensation takes advantage of the fact that most lighting systems are overdesigned to account for a gradual reduction of light output of lamps as they advance in operating age. Similar to daylight harvesting, this strategy entails measuring available light in the space and dimming the light output to maintain a constant level.

Demand control involves switching or dimming lighting systems during utility peak demand periods, which results in energy cost savings and also potentially significantly lowers demand charges (Tables 2 and 3).

TYPICAL CONTROLS

Lighting controls generally can be categorized as manual or automatic, although some may have features of both types of operation. Manual controls require immediate human intent to turn the lighting on or off or adjust its output. Automatic controls initiate actions for lighting systems based on registered events or programming.

Fig. 2 A growing number of light fixtures are now available with integrated automatic lighting controls, such as this recessed basket, which includes an integrated sensor.

Table 1 Benefits of automatic lighting controls in various space types

| Space type | Benefit |

| Discount retail store | In an open retail space with daylighting, dimming can reduce electric lighting use but allow the lights to be on, making the store seem “open for business” |

| Conference room, classroom, auditorium, etc. | Dimming lighting can facilitate a variety of visual presentations |

| Health care facility | Daylight-driven dimming can provide a smooth and unnoticeable transition to electric lighting as daylight levels decrease, while maintaining the desired light level |

| Restaurant | Preset scene dimming controls can make changing the ambiance as the day goes on consistent and as easy as pressing a button |

| Office area | Even in an open office area, occupants can be given the option of dimming the light fixture over their workstation to suit their personal preferences |

Control options can be grouped as switching controls, dimming controls, and integrated lighting control systems.

Switching controls turn lights on and off, and many perform other functions as well. At a minimum, every space should be equipped with manual switching to permit occupants or facility operators to control lighting usage.

Lighting contactors: lighting contactors permit manual or automatic control of large blocks of lighting loads.

Local wall switches: local wall switches (a.c. snap switches) are the most commonly used control devices for local lighting control. For best results, switches should be located to be convenient to users and to encourage deactivation of lighting whenever appropriate. Wall switches also can be applied to develop a flexible lighting control scheme by layering the lighting in the space, with different layers controlled by different switches.

Key-activated switches: key-activated switches are wall switches that turn lighting on and off by a key. They are installed to prevent unauthorized or accidental use of certain lighting circuits. They are particularly useful for HID light sources that must cool down before they can be activated.

Intelligent on/off local devices: intelligent on/off local devices consist of at least two elements: (1) a logic or intelligence module, and (2) a power switching device. The logic or intelligence elements vary depending on the needs of the specific applications. The intelligent input in its simplest form can be a time control or an occupancy sensor. Each typically is used to control a single load and is wired directly to it.

Time controls, also known as time clocks or time switches, activate and deactivate their loads at user-determined times, and are therefore most suitable for areas where occupancy is predictable (with local overrides often being desirable). Some are microprocessor based, allowing operators to program more on/off actuations per day, as well as create special schedules for holidays or certain functions. Outdoor lighting time controls often use an astronomical feature that automatically compensates the control schedule for sunrise and sunset time shift during the year.

Fig. 3 Typical weekday lighting schedule.

Table 2 Typical lighting control applications

| Typical lighting

Type of control |

control appl-

cations Private office |

Open office— daylit |

Open office— interior |

| Occupancy | + + | + + | + + |

| sensors | |||

| Time | + | + + | + + |

| scheduling | |||

| Daylight | + + | + + | 0 |

| dimming | |||

| Bi-level | + + | + | + |

| switching | |||

| Demand | + | + + | + + |

| lighting |

+ +, good savings potential; +, some savings potential; 0, not applicable.

Occupancy sensors are automatic switches that control lighting based on the presence or absence of people (see Figs. 5 and 6). Their primary function is to switch electric illumination off automatically in an unoccupied space after the last person leaves that space, saving energy (see

Table 4 Typical energy savings with occupancy sensors

| Occupancy area | Energy savings (%) |

| Private office | 13-50 |

| Classroom | 40-46 |

| Conference room | 22-65 |

| Restrooms | 30-90 |

| Corridors | 30-80 |

| Storage areas | 45-80 |

Table 4). A timing control provides light for a period of time after the area is vacated.

Photocell controls respond to changes in ambient light. When the ambient light level falls to a user-determined level, lighting is switched on. When the ambient light increases to a user-determined level, lighting is switched off.

Low-voltage controls: low-voltage switching systems provide a more flexible switching platform than standard line-voltage switches. The simplest system consists of a transformer that produces 24 V or less, relays that are wired to the loads, and on/off switches that are connected by low-voltage wiring to the relays. Each relay can control up to one full branch circuit (20 A).

Table 3 Operating cost comparisons for private office and open office spaces, using various types of controls

Operating cost comparison private office, 128 ft2

| Performance | Base case | Occupancy sensors | Daylighting | Occupancy sensorC daylighting |

| Annual energy usea | 450 kWh | 340 kWh | 330 kWh | 250 kWh |

| Annual energy cost | $33 | $24 | $24 | $18 |

| Annual energy cost savings | — | $9 | $9 | $15 |

Operating cost comparison open office area, 1000 ft2

| Performance | Base case | Time scheduling | Occupancy sensors | Daylighting | Time schedulingC daylighting |

| Annual energy | 5700 kWh | 5100 kWh | 5000 kWh | 4200 kWh | 3700 kWh |

| useb | |||||

| Annual energy | $340 | $305 | $300 | $250 | $220 |

| cost | |||||

| Annual energy | — | $35 | $40 | $90 | $120 |

| cost savings |

Fig. 4 Lighting control panel installation.

Fig. 5 Occupancy sensors.

Fig. 6 Occupancy sensor system.

Low-voltage wiring provides inherent wiring flexibility while also providing the foundation for simple lighting automation (Fig. 7).

Step-level HID controls: step-level HID lighting controls are relay systems that operate mercury vapor, metal halide, and high-pressure sodium lighting at either full light output or less (e.g., 50%) (Fig. 8).

Dimming controls are available for most types of lighting. They can be integrated into automatic lighting control systems and can be used manually as well. Some dimming controls require use of dimming ballasts, while others employ an electronics package installed in the panelboard or elsewhere within the system.

Wallbox dimmers: wallbox dimmers are manual controls that give occupants more control over their visual environment. Various control configurations are available, including linear slides, rotary knobs, raise/lower buttons, preset panels, and wireless remotes.

Integrated dimmers: integrated dimmers integrate a variety of features into a wallbox configuration. Commonly included features are multiple channel control, with which all or selected fixtures on a circuit are controlled by a single dimmer; multiple presets; and universal circuitry that allows each dimming channel to control incandescent, low-voltage incandescent, fluorescent, cold-cathode, or neon light sources (Fig. 9).

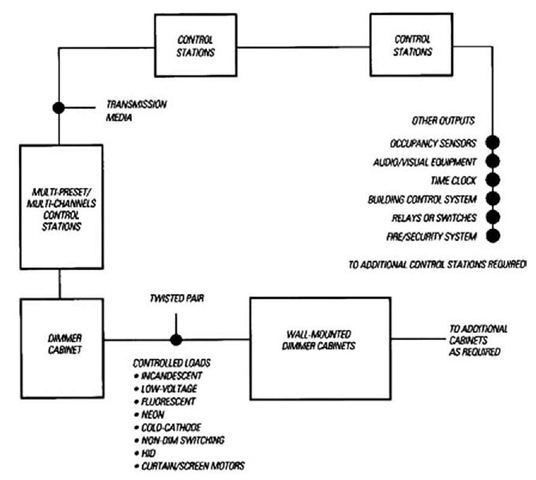

System dimmers: system dimmers offer lighting control for larger applications in which wallbox and integrated products are impractical or higher performance is required. These systems consist of dimmer cabinets and control stations, typically connected with low-voltage control wires (Fig. 10).

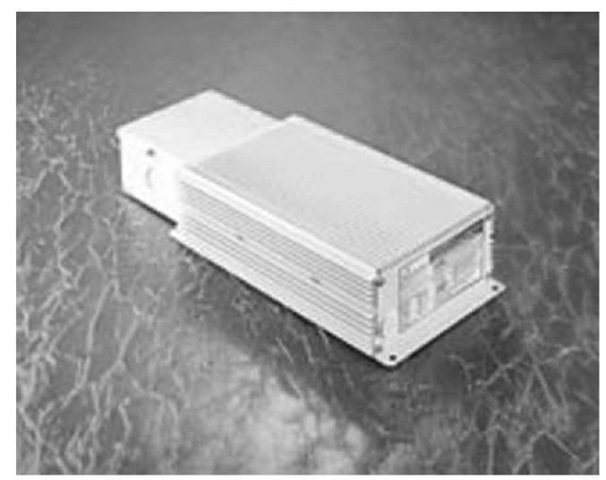

Dimming ballasts: variable output ballasts integrate dimming capability into fluorescent (see Fig. 11) and HID (see Fig. 12) ballasts so that they can dim the lamps according to manual, scheduled, or event-based input. An example of manual input is giving each occupant personal dimming control of his or her lighting system. An example of scheduled input is dimming the lamps across areas of a facility at preset times of day for demand control. An example of event-based input is daylight harvesting, in which a photocell is used to measure light levels, and the ballast dims the lamps to maintain a preset light level based on whether ample daylight is available.

Programmed-start ballasts: most available dimming ballasts for fluorescent lamps are rapid-start electronic ballasts or programmed-start electronic ballasts. Programmed-start ballasts are of interest with or without dimming capability. They are rapid-start ballasts that preheat the electrodes more accurately to minimize damage to the electrodes during the startup process (according to a program), and therefore can optimize lamp life. While supplying the preheat voltage, the ballast minimizes the lamp voltage, thereby reducing glow current during this phase with its associated degrading effect on lamp life. As a result, programmed-start ballasts can provide up to 100,000 starts, ideal for applications where the lamps are frequently switched, such as spaces with occupancy sensors.

Fig. 7 Low-voltage control system schematic.

Fig. 8 Schematic of two-level HID lighting control system.

Integrated lighting control systems consist of manual or automatic components designed to control compatible dimming ballasts. They can be interfaced with other microprocessor-based centralized lighting control systems or building automation systems. These systems can perform all of the functions that are important to energy optimization. They can sense conditions in each area or zone and control lighting to yield maximum energy efficiency without affecting visual comfort or other conditions (Fig. 13).

Fig. 9 Dimming system.

Fig. 10 System dimmer.

Microprocessor-based centralized programmable lighting control: a microprocessor-based centralized programmable lighting control system is basically a microprocessor-based centralized controller. Although it is designed principally for lighting, it is capable of handling other loads. Photocells and other controls can be integrated into the system.

Fig. 11 Fluorescent dimming ballast.

Fig. 12 HID dimming ballast. HID dimming ballasts are relatively new and are growing in popularity.

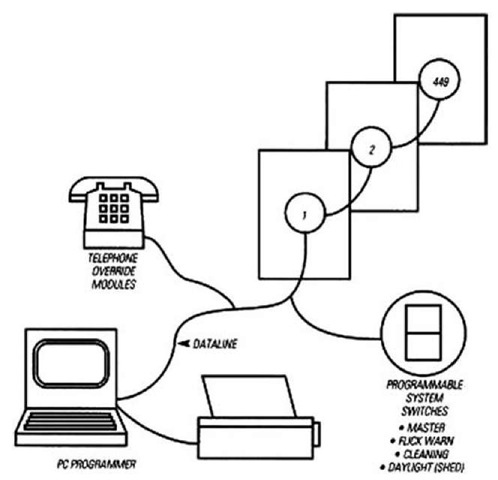

Microprocessor-based programmable controllers can be integrated into networked lighting control systems that allow schedules and other programmable functions to be entered and then changed from a central operator console. Networked systems also allow input from devices such as master switches, photocells, occupancy sensors, telephones, or load-shed contacts to control relays or dimmers. In addition, the network allows the central collection of operating data and status information.

The typical networked control system shown in Fig. 14 provides automated lighting control for applications ranging from a small office building to a mall to an industrial complex. Each of the distributed control panels has standalone automation capability. The network links these controllers to a central operator terminal (PC). Besides supporting such features as telephone control and distributed master switching, these systems can provide energy management data. Providing networked lighting controls also ensures that the lighting can be effectively integrated with other building controls (controlling security, etc.) to provide full intelligent lighting operation.

Building automation systems: building automation controls generally are microcomputer- or minicomputer-based systems that are capable of controlling lighting systems as well as HVAC, security, and fire safety systems.

EVALUATING LIGHTING CONTROL OPTIONS

Once the general type of control system has been decided upon, the next step is specifying the specific control devices. In order to do so, it is essential to establish criteria for evaluating options. Some of the key criteria to consider are given below.

Cost-effectiveness: lighting controls that reduce energy consumption and/or reduce demand are an investment in profitability. Control options should be evaluated based on initial installed cost vs operating cost savings to determine return on investment and the payback period. Options that generate the highest return on investment and meet other selection criteria are more desirable.

Fig. 13 Integrated lighting control system.

Fig. 14 Networked intelligent panels.

Adaptability: for projects in existing facilities, lighting controls should be evaluated based on how well they can be adapted to the facility, and how advantageous they will be. For example, can the new control system be interfaced existing local controls, or will the controls have to be replaced? If daylight harvesting is of interest, is there sufficient daylight to warrant it? Adaptability applies not only to applying controls to existing spaces; but also to ensuring, in both existing spaces and new construction, that the control system is scalable to future space use and potential advances in technology.

Flexibility: controls can be evaluated based on the degree of flexibility required from the lighting system, which in turn is based on how the space is used. In a gymnasium, for example, a variety of activities can occur, from sporting events to assemblies and plays. A flexible lighting system enabled by appropriate controls can respond to all of these uses.

Maintainability: maintainability refers to the ease with which a system is maintained, something determined through evaluation of two principal factors: (1) in-house maintenance support through training programs and manuals, and (2) the availability of professionally trained maintenance persons employed, licensed, or authorized by the manufacturer.

Wiring diagrams of the system also are essential during maintenance procedures; someone who understands the diagrams must be available. Do not assume that a given manufacturer can always provide effective maintenance on a timely basis. Check references to determine how satisfied other users of the proposed system are with the maintenance services provided. Key concerns in this regard are completeness of preventive maintenance, responsiveness and capability of outside maintenance, and the availability of a service maintenance agreement.

Reliability: reliability relates to how well the system performs and the way in which it performs. System performance can be determined primarily by talking with other users of the system. They can relate how often breakdowns occur and the time required to restore equipment to its pre-failure condition. Most modern controls are highly reliable.

Programmability: programmability is the degree to which the programming capability of a microprocessor-based lighting control system can be modified. Many programs are written in such a way that they can be modified relatively easily, either by the user or the manufacturer.

Complexity: lighting control options can be evaluated by their ease of specification, installation, programming, commissioning, and ongoing use.

Interoperability: all components of a desired control system, which may include components as diverse as relays, photocells, dimmers, dimming ballasts, and software, must be electrically compatible and operate reliably properly as a system. This may require consideration of control voltage and also operating protocol such as 0-10VDC, DALI, and BACnet.

APPLICATION ISSUES

Design controls for each area: the first step is to systematically evaluate all the parameters involved in the design in light of the design goals. For each area, the designer will need to determine which components will be most appropriate. At the same time, the designer will need to decide on the optimum placement for each component. Often, the control manufacturer can offer valuable assistance for each phase of the project, from evaluation to providing wiring diagrams to give to the contractor.

Zoning for occupancy recognition: occupancy recognition controls can improve usability, security, and efficiency in a building. However, they can be bypassed or even removed by the owner if not applied properly. The designer should take into account how the space is used, including how it’s occupied. For example, if an employee shows up on a Saturday, the entire floor’s lighting should not activate, only the local areas the employee is using. Similarly, if the employee is sitting at his or her desk, the lights should stay on by continually detecting their occupancy.

Prevailing energy codes: require the use of automatic lighting controls. The U.S. Department of Energy, via a ruling under the Energy Policy Act of 1992, now requires that all states have an energy code at least as stringent as ASHRAE/IES Standard 90.1-1999.

Table 5 Selection of controls for various types of spaces: room by room analysis

| Space type | Use pattern | IF… |

| Cafeterias or lunchrooms | Occupied occasionally | Daylighted… Occupied occasionally |

| Class room | Usually occupied occasionally occupied | Multi-tasks like overhead projectors, chalkboard, student note taking and reading, class demonstrations

Occupied by different students and teachers Lights left on after hours |

| Computer room | Usually unoccupied | Lights are left on all the time |

| Conference room | Occupied occasionally | Multi-tasks from video-conferencing to presentations |

| Small conference room | ||

| Large conference room | ||

| Gymnasium or fitness | Usually occupied | Requires varied lighting levels for activities |

| Hallways | Any | Occasionally or usually occupied Daylighted… |

| Health care— examination rooms | Occasionally occupied | Different lighting needs for examination |

| Small areas | ||

| Health care—hallways | Usually occupied | Daylighted…

Requires lower lighting level at night |

| Health care—patient rooms | Usually occupied | Different lighting needs for watching television, reading, sleeping and examination |

| Hotel rooms | Occasionally occupied | Use primarily in the late afternoon through evening for sleeping and relaxing |

| Laboratories | Usually occupied | Daylighted… |

Consider daylight-driven dimming or on/off control

Consider ceiling-mounted occupancy sensor(s). Make sure minor motion will be detected in all desired locations Consider manual dimming

Consider ceiling- or wall-mounted occupancy sensor(s) and manual dimming. Make sure that minor motion will be detected Consider centralized controls and/or occupancy sensors Consider occupancy sensors with manual dimming. Be sure that minor motion will be detected and that equipment vibration will not falsely trigger the sensor

Consider manual dimming (possibly preset scene control) Consider a wall box occupancy sensor

Consider ceiling- or wall-mounted occupancy sensor(s). Be sure that

minor motion will be detected in all desired locations

Consider manual dimming and occupancy sensors. Be sure that the

HVAC system will not falsely trigger the sensor

Consider occupancy sensors with elongated throw. Be sure that

coverage does not extend beyond the desired area

Consider daylight on/off control

Consider manual dimming

Consider a wall box occupancy sensor Consider automatic daylight-driven dimming Consider centralized controls to lower lighting levels at night Consider manual dimming. Occupancy sensors may not be appropriate

Consider manual dimming

Consider automatic daylight-driven dimming in combination with occupancy sensors

Table 5 Selection of controls for various types of spaces: room by room analysis (Continued)

| Space type | Use pattern | IF… |

| Laundry rooms | Occasionally occupied | Requires high light levels, yet lights are usually left on |

| Libraries—reading areas | Usually occupied | Daylight…

Lights left on after hours |

| Libraries—stack areas | Occasionally occupied | Stacks are usually unoccupied |

| Lobby or atrium | Usually occupied but no one “owns” the space | Daylighted and lights should always appear on… |

| It isn’t a problem if lights go completely off in | ||

| high daylight… | ||

| Lights are left on all night long, even when no | ||

| one is in the area for long periods | ||

| Office, open | Usually occupied | Daylighted… |

| Varied tasks from computer usage to reading | ||

| Lights left on after hours | ||

| Office, private | Primarily one person, | Daylighted… |

| coming and going | Occupants are likely to leave lights on and occupants would be in direct view of a wall box sensor | |

| Occupants are likely to leave lights on and partitions or objects could hide an occupant from the sensor | ||

| Photocopying, sorting, | Occasionally occupied | Lights are left on when they are not needed |

| assembling | ||

| Restaurant | Usually occupied | Daylighted |

| Requires different lighting levels throughout the day | ||

| Requires different lighting levels for cleaning | ||

| Restroom | Any | Has stalls |

| Single toilet (no partitions) | ||

| Retail store | Usually occupied | Daylighted… |

Consider occupancy sensors

Consider automatic daylight-driven dimming

Consider centralized controls Consider ceiling-mounted sensor(s) Consider automatic daylight-driven dimming

Consider automatic daylight-driven dimming or on/off control

Consider occupancy sensors. Be sure that minor motion will be detected in all desired areas

Consider automatic daylight-driven dimming

Consider manual dimming

Consider centralized controls and/or occupancy sensors Consider manual dimming, automatic daylight-driven dimming, or automatic on/off

Consider a wall box occupancy sensor

Consider a ceiling- or wall-mounted occupancy sensor

Consider an occupancy sensor. Be sure that machine vibration will not falsely trigger the sensor

Consider automatic daylight-driven dimming

Consider manual dimming (possibly preset scene dimming)

Consider centralized control

Consider a ceiling-mounted ultrasonic occupancy sensor for full coverage

Consider a wall switch occupancy sensor Consider automatic daylight-driven dimming

| Warehouse | Aisles are usually | Different lighting needs for retail sales,

stocking, cleaning Daylighted |

Consider centralized controls or preset scene dimming control Consider daylight-driven dimming or daylight on/off control |

| unoccupied | Lights in an aisle can be turned off when the aisle is unoccupied | Consider ceiling-mounted occupancy sensors with elongated throw. Select a sensor that will not detect motion in neighboring aisles, even when shelves are lightly loaded |

Utility rebates and incentives: a number of utilities continue to offer financial incentives for organizations that upgrade their lighting systems. The incentive may take the form of cash for installing approved technologies or cash per removed unit of energy consumption or demand.

Electrical design: lighting control systems should be designed using all appropriate code rules and design practices related to overload, short-circuit protection, grounding, and other safety concerns. Be sure the control system can handle the steady-state current, lamp inrush, ballast harmonics, and available fault currents (which may entail tradeoffs among these factors). Do the electrical design before working out the details of the control scheme. For example, ensure that there is sufficient space in the electrical closet for needed components (Table 5).

Switching vs dimming: in daylight harvesting and similar schemes, switching lamps can be jarring if it occurs frequently during the day. Smooth dimming between light levels is less noticeable by occupants.

Layering control systems: a number of buildings utilize schedule-based systems as a global switching system and supplement them with occupancy sensors, manual switches, and dimming systems as needed. The schedule-based system activates and shuts off zones or the entire building based on predicted occupancy; the occupancy sensors and manual switches provide local override and automatic off after occupants leave; and dimming is used for architectural spaces, conference rooms, and areas of opportunity for daylight harvesting. Additional overrides can be provided by telephone or network interface for unusual circumstances. Zones should be sufficiently small for flexibility and maximum savings, although one should be aware of additional installed cost if zones are too small. Ensure that changing the schedule is easy, and that the system provides a flexible design that allows for different schedules for areas of the building with different needs and alternate schedules for weekends and holidays (Fig. 15).

Select products: depending on the relative importance of the several factors, select appropriate components and test the integrated design to see if it will satisfy the goals. Watch out for mismatched components. For fluorescent lighting, ballasts and controls must be compatible. Fluorescent fixtures that are intended to be dimmed require special dimming ballasts. There are several kinds of control systems, and likewise, there are several varieties of dimming ballasts. For the switching of outdoor lighting systems, a more robust device will likely be needed than those used indoors.

Control voltage: some controls can be connected to line-voltage power, while others must be connected to low-voltage (d.c.) power. Line-voltage controls tend to be less expensive, but less flexible, than low-voltage controls. They may also be more cost-effective for retrofits. In many cases, however, control systems require low-voltage control because low-voltage components such as light-level sensors are present.

Fig. 15 Lighting automation with local switch override.

Equipment location: as the designer locates the controls, he or she should ask if their placement is appropriate. Controls should be easy to locate and access for use or maintenance. Partitions and walls will affect the coverage patterns of sensors. For occupancy sensors, be aware of space considerations that could result in false triggering. The “brains” of lighting control systems should be mounted near the lighting panelboards in the electrical closets, requiring sufficient space (Table 6).

Typical coverage patterns (applies to occupancy sensors): there are several different kinds of coverage patterns and mounting configurations for occupancy sensors, such as ceiling-mounted controls with 360° coverage, ceiling-mounted controls with elongated “corridor” coverage, wall-mounted controls with a fan-shaped coverage pattern, and ceiling-mounted controls with a rectangular coverage pattern. Take note of the difference between each device’s sensitivity to minor motion (working at a desk) vs major motion (walking or half-step activity). The manufacturer should provide coverage diagrams for both levels of activity.

Light levels: watch out for inadequate light levels. Make sure that set points are selected that will please the majority of the occupants. Get their input if possible. Follow IESNA recommendations based on the type of tasks performed in the area.

Ease of use and maintenance: the controlled lighting should be seen from the control panel or switch location. If the controls adapt to the normal behavior of people, they will be accepted by occupants. If not, they will be rejected. Similarly, if controls aren’t simple, they will not be used. Controls should make sense and provide flexibility to all users.

Security issues: in high-security applications, occupancy sensors will indicate that people are present wherever lights are on. It is also advisable that, in these areas, there should be no manual-off option, and sensors should be protected from tampering and vandalism.

Construction documents: a complete set of construction documents includes, but is not necessarily limited to, (1) drawings, showing control locations, circuiting, and a control zone diagram to show which light fixtures are controlled by which device and how the controls are interrelated; (2) wiring diagrams for control components; (3) a schedule of controls, showing catalog numbers and descriptions of selected products (including all necessary power packs and accessories); and (4) written specifications for the control system, explaining the work and submittals included and clearly describing the approved equipment needed to achieve the desired results.

Installation: it pays to make sure the contractor understands the way the control scheme works. In one high-profile project, the light-level sensors were supposed to be installed underneath the indirect light fixtures. Instead, they were initially installed on top of them. When the sensors determined that more light was needed, they turned the lights on. But, when the lights came on, they shone on the sensors—so off they went again.

Commissioning: when the installation is complete, the controls should be commissioned, which often includes ensuring that (1) light-level or delay-time set points are set, (2) dip switches are set, (3) sensors are aimed for maximum accuracy, (4) preset dimming scenes are set, and (5) the system is tested to make sure it functions as intended. Commissioning and calibration of lighting controls are essential if energy savings are to be achieved and maintained. Occupancy sensors with sensitivity set too high can fail to save energy, but occupancy sensors with too low a sensitivity or too short a delay time can be annoying to occupants. Similarly, improperly adjusted daylight dimming controls can dim the lights too low, causing occupants to override them (e.g., by taping over the sensor), or can fail to dim the lights at all. Choose daylight sensors that can be calibrated quickly and easily, and take the time to calibrate them correctly. The dimming adjustment should be easily accessible to the installer and provide an acceptable range of dimming.

Table 6 Questions to ask lighting control system vendors

| Financial arrangements | What is the total installed cost of the system and what does it include? Over what time period must it be paid?

Will the supplier provide certain services? What are they? Can the equipment be leased or rented? How much is it? What does the cost include (and exclude)? What are the delivery lead times? |

| Reliability | How many units of the model under consideration are currently installed? When was the first unit of this model installed?

What is the term of warranty and what does it cover? Under what circumstances can the warranty be extended? Will the seller warrant against damage to any other purchaser’s equipment? What are the general liability limits and how are claims settled? |

| Maintenance | How much does it cost and what does it cover?

What schedules are available? (Most companies offer many schedules, depending on the response time and coverage desired.) Where is the nearest service office? Have they been trained on the piece of equipment being considered? (If this equipment is the only model of that type installed, chances are that a great deal of on-the-job training will be provided for in-house service people.) What spare parts are recommended? How many different modules does the system have? Does the company selling and installing the equipment also manufacture and service it? Is the system configured so that it can be backed up? |

| References | Who in the area is using this model equipment? How is it being used?

Is the application comparable to the one being contemplated? How long has the equipment been in place? |

| Training | How much training is required?

Is it included in the purchase price? How much does extra training cost? Where does training take place? How long will it last? |

| General | Is applications support generally required?

Can the system be expanded or upgraded easily? How much will expansion cost? What is generally involved? |

User education: it’s often beneficial to educate users about how to use their controls and get them excited.

CONCLUSIONS

Lighting controls are an exciting field in lighting as lighting automation technology rapidly advances and maturity increases reliability and capabilities while decreasing complexity and cost. Lighting automation is proven to save energy while potentially increasing flexibility, security, space marketability, worker satisfaction and aesthetics. A large number of technologies and strategies are available to achieve desired results and performance for virtually any popular application.