1.2

There are many types of single-phase electric motors. In this section, the discussion will be limited to those types most common to integral-horsepower motor ratings of 1 hp and higher.

In industrial applications, three-phase induction motors should be used wherever possible. In general, three-phase electric motors have higher efficiency and power factors and are more reliable since they do not have starting switches or capacitors.

In those instances in which three-phase electric motors are not available or cannot be used because of the power supply, the following types of single-phase motors are recommended for industrial and commercial applications: (1) capacitor-start motor, (2) two-value capacitor motor, and (3) permanent split capacitor motor.

A brief comparison of single-phase and three-phase induction motor characteristics will provide a better understanding of how single-phase motors perform:

1. Three-phase motors have locked torque because there is a revolving field in the air gap at standstill. A single-phase motor has no revolving field at standstill and therefore develops no locked-rotor torque. Anauxiliary winding is necessary to produce the rotating field required for starting. In an integral-horsepower single-phase motor, this is part of an RLC network.

2. The rotor current and rotor losses are insignificant at no load in a three-phase motor. Single-phase motors have appreciable rotor current and rotor losses at no load.

3. For a given breakdown torque, the single-phase motor requires considerably more flux and more active material than the equivalent three-phase motor.

4. A comparison of the losses between single-phase and three-phase motors is shown in Fig. 1.11. Note the significantly higher losses in the single-phase motor.

The general characteristics of these types of single-phase induction motors are as follows.

1.2.1

Capacitor-Start Motors

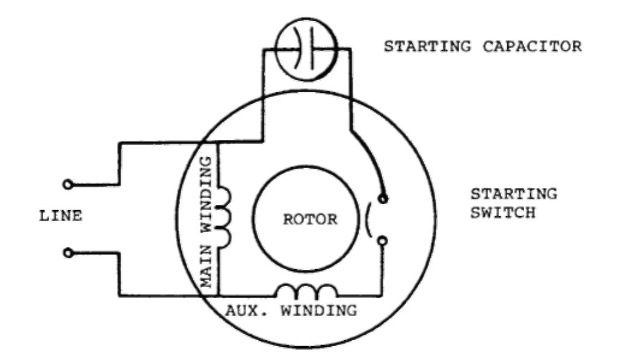

A capacitor-start motor is a single-phase induction motor with a main winding arranged for direct connection to the power source and an auxiliary winding connected in series with a capacitor and starting switch for disconnecting the auxiliary winding from the power source after starting. Figure 1.12 is a schematic diagram of a capacitor-start motor. The type of starting switch most commonly used is a centrifugally actuated switch built into the motor. Figure

FIGURE 1.11 Percent loss comparison of single- and three-phase motors.

FIGURE 1.12 Capacitor-start single-phase motor.

1.13 illustrates an industrial-quality drip-proof single-phase capacitor-start motor; note the centrifugally actuated switch mechanism.

However, other types of devices such as current-sensitive and voltage-sensitive relays are also used as starting switches. More recently, solid-state switches have been developed and used to a

FIGURE 1.13 Capacitor-start single-phase motor. (Courtesy Magnetek, St. Louis, MO.)

limited extent. The solid-state switch will be the switch of the future as it is refined and costs are reduced.

All the switches are set to stay closed and maintain the auxiliary winding circuit in operation until the motor starts and accelerates to approximately 80% of full-load speed. At that speed, the switch opens, disconnecting the auxiliary winding circuit from the power source.

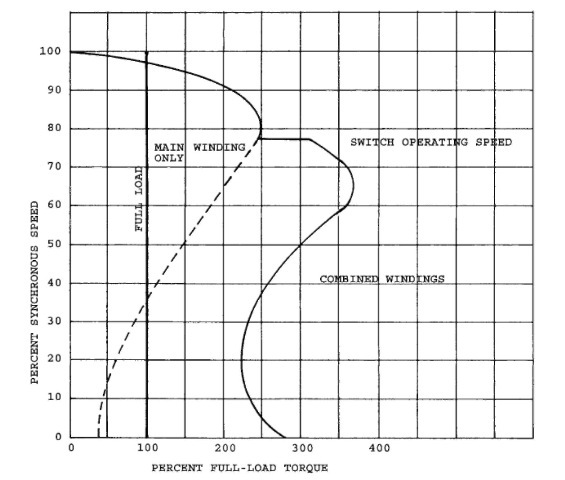

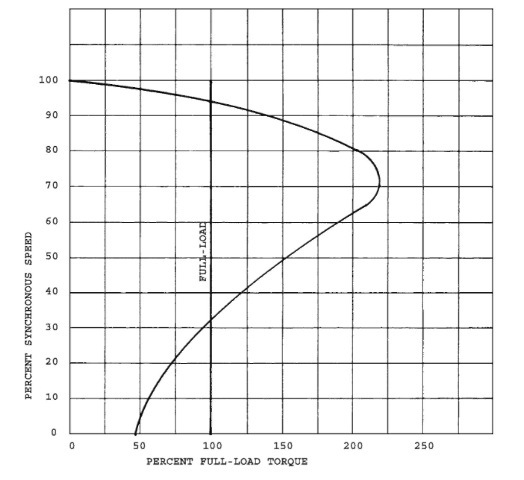

The motor then runs on the main winding as an induction motor. The typical speed-torque characteristics for a capacitor-start motor are shown in Fig. 1.14. Note the change in motor torques at the transition point at which the starting switch operates.

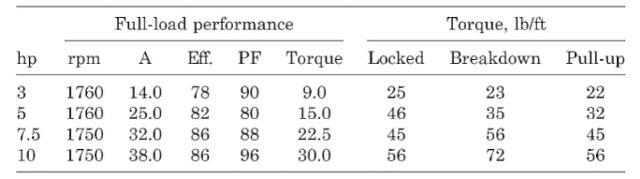

The typical performance data for integral-horsepower, 1800-rpm, capacitor-start, induction-run motors are shown in Table 1.6. There will be a substantially wider variation in the values of locked-rotor torque, breakdown torque, and pull-up torque for these single-phase motors than for comparable three-phase motors, and the same variation also exists for efficiency and the power factor (PF). Note that pull-up torque is a factor in single-phase motors to ensure starting with high-inertia or hard-to-start loads. Therefore, it is important to know the characteristics of the specific capacitor-start motor to make certain it is suitable for the application.

1.2.2

Two-Value Capacitor Motors

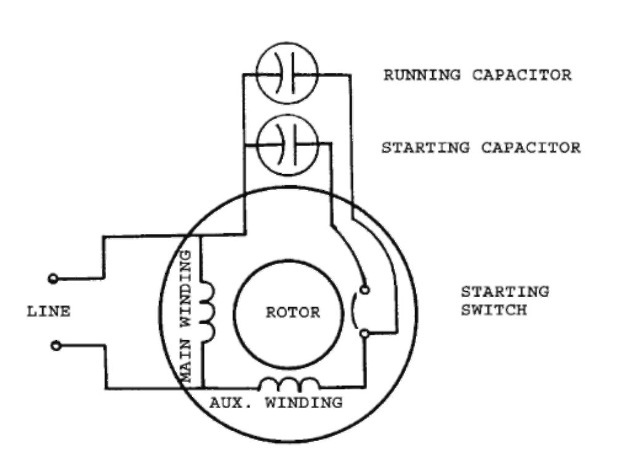

A two-value capacitor motor is a capacitor motor with different values of capacitance for starting and running. Very often, this type of motor is referred to as a capacitor-start, capacitor-run motor.

The change in the value of capacitance from starting to running conditions is automatic by means of a starting switch, which is the same as that used for the capacitor-start motors. Two capacitors are provided, a high value of capacitance for starting conditions and a lower value for running conditions. The starting capacitor is usually an electrolytic type, which provides high capacitance per unit volume. The running capacitor is usually a metallized polypropylene unit rated for continuous operation. Figure 1.15 shows one method of mounting both capacitors on the motor.

The schematic diagram for a two-value capacitor motor is shown in Fig. 1.16. As shown, at starting, both the starting and running

FIGURE 1.14 Speed-torque curve for a capacitor-start motor.

capacitors are connected in series with the auxiliary winding. When the starting switch opens, it disconnects the starting capacitor from the auxiliary winding circuit but leaves the running capacitor in series with the auxiliary winding connected to the power source. Thus, both the main and auxiliary windings are energized when the motor is running and contribute to the motor output. A typical

TABLE 1.6 Typical Performance of Capacitor-Start Motors3

| hp | Full-load performance | Torque, lb-ft | |||||

| rpm | A | Eff. | PF Torque | Locked | Breakdown | Pull-up | |

| 1 | 1725 | 7.5 | 71 | 70 3.0 | 9.9 | 7.5 | 7.6 |

| 2 | 1750 | 12.5 | 72 | 72 6.0 | 17.5 | 14.7 | 11.5 |

| 3 | 1750 | 17.0 | 74 | 79 9,0 | 23,0 | 21.0 | 18,5 |

| 5 | 1745 | 27.3 | 78 | 77 15.0 | 46.0 | 32.0 | 35.0 |

a Four-pole, 230-V, single-phase motors. Source: Courtesy Magnetek, St. Louis, MO.

speed-torque curve for a two-valve capacitor motor is shown in Fig. 1.17.

For a given capacitor-start motor, the effect of adding a running capacitor in the auxiliary winding circuit is as follows:

Increased breakdown torque: 5-30% Increased lock-rotor torque: 5-10% Improved full-load eciency: 2-7 points

FIGURE 1.15 Two-value capacitor, single-phase motor. (Courtesy Magnetek, St. Louis, MO.)

FIGURE 1.16 Two-value capacitor, single-phase motor.

Improved full-load power factor: 10-20 points Reduced full-load running current Reduced magnetic noise Cooler running

The addition of a running capacitor to a single-phase motor with properly designed windings permits the running performance to approach the performance of a three-phase motor. The typical performance of integral-horsepower, two-value capacitor motors is shown in Table 1.7. Comparison of this performance with the performance shown in Table 1.6 for capacitor-start motors shows the improvement in both efficiency and the power factor.

The optimum performance that can be achieved in a two-value capacitor, single-phase motor is a function of the economic factors as well as the technical considerations in the design of the motor. To illustrate this, Table 1.8 shows the performance of a single-phase motor with the design optimized for various values of running capacitance. The base for the performance comparison is a capacitor-start, induction-run motor with no running capacitor. Table 1.9 shows that performance improves with increasing values

FIGURE 1.17 Speed-torque curve for a two-value capacitor motor.

of running capacitance and that the motor costs increase as the value of running capacitance is increased. The payback period in years was calculated on the basis of 4000 hr/yr of operation and an electric power cost of 6^/kWh. Note that the major improvement in motor performance is made in the initial change from a capacitor-start to a two-value capacitor motor with a relatively low value of running capacitance. This initial design change also shows the shortest payback period.

The determination of the optimum two-value capacitor motor for a specific application requires a comparison of the motor costs and the energy consumptions of all such available motors. It is

TABLE 1.7 Typical Performance of Two-Value Capacitor Motors3

a Four-pole, 230-V, single-phase motors. Source: Courtesy Magnetek, St. Louis, MO.

recommended that this comparison be made by a life-cycle cost method or the net present worth method (outlined in topic 7).

The efficiency improvement and energy savings of a specific product line of pool pump motors when the design was changed from capacitor-start motors to two-value capacitor motors are illustrated by Table 1.9 and Figs. 1.18 and 1.19. Based on the same operating criterion used above, i.e., 4000-hr/yr operation at power costs of 6^/kWh, the payback period for these motors was 8-20 months.

TABLE 1.8 Performance Comparison of Capacitor-Start and Two-Value Capacitor Motors

| Type of motor | |||||

| Capacitor start | Two-value capacitor | ||||

| Running capacitor, MFD | 0 | 7.5 | 15 | 30 | 65 |

| Full-load efficiency | 70 | 78 | 79 | 81 | 83 |

| Full-load PF | 79 | 9-1 | 97 | 99a | 99:l |

| Input watts reduction, % | 0 | 10.1 | 11,5 | 13,3 | 15 |

| Cost, % | 100 | 130 | 110 | 151 | 196 |

| Approximate payback period | — | 1.3 | 1.0 | 1.8 | 2.9 |

a Leading power factor.

TABLE 1.9 Efficiency Comparison: Standard and Energy-Efficient 3600-rpm, Single-Phase Pool Motors

| hP | Standard efficient motors | Energy-efficient motors |

| 0.75 | 0.677 | 0.76 |

| 1.00 | 0.709 | 0.788 |

| 1.50 | 0.749 | 0,827 |

| 2.00 | 0.759 | 0.85 |

| 3.00 | 0.809 | 0.869 |

FIGURE 1.18 Efficiency comparison of energy-efficient and standard pool pump single-phase motors. (Courtesy Magnetek, St. Louis, MO.)

FIGURE 1.19 Annual savings for a 1-hp energy-efficient pool motor operating 365 days/yr. (Courtesy Magnetek, St. Louis, MO.)

1.2.3

Permanent Split Capacitor Motors

The permanent split capacitor motors, a single-phase induction motor, is defined as a capacitor motor with the same value of capacitance used for both starting and running operations. This type of motor is also referred to as a single-value capacitor motor. The application of this type of single-phase motor is normally limited to the direct drive of such loads as those of fans, blowers, or pumps that do not require normal or high starting torques. Consequently, the major application of the permanent split capacitor motor has been to direct-driven fans and blowers. These motors are not suitable for belt-driven applications and are generally limited to the lower horsepower ratings.

The schematic diagram for a permanent split capacitor motor is shown in Fig. 1.20. Note the absence of any starting switch. This type of motor is essentially the same as a two-value capacitor motor

FIGURE 1.20 Permanent split capacitor single-phase moto

operating on the running connection and will have approximately the same torque characteristics. Since only the running capacitor (which is of relative low value) is connected in series with the auxiliary winding on starting, the starting torque is greatly reduced. The starting torque is only 20-30% of full-load torque. A typical speed-torque curve for a permanent split capacitor motor is shown in Fig. 1.21. The running performance of this type of motor in terms of efficiency and power factor is the same as a two-value capacitor motor. However, because of its low starting torque, its successful application requires close coordination between the motor manufacturer and the manufacturer of the driven equipment.

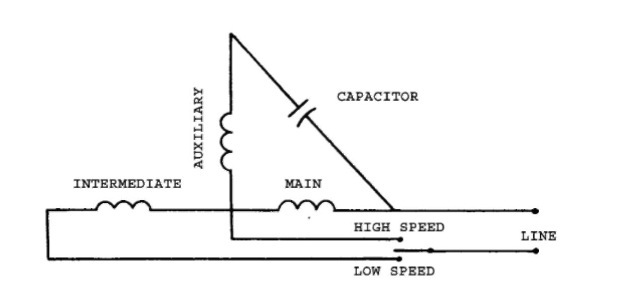

A special version of the capacitor motor is used for multiple-speed fan drives. This type of capacitor motor usually has a tapped main winding and a high-resistance rotor. The high-resistance rotor is used to improve stable speed operation and to increase the starting torque. There are a number of versions and methods of winding motors. The most common design is the two-speed motor, which has three windings: the main, intermediate, and auxiliary windings. For 230-V power service, a common connection of the windings is called the T connection. Schematic diagrams for two-speed T-connected motors are shown in Figs. 1.22 and 1.23. For

FIGURE 1.21 Speed-torque curve for a permanent split capacitor motor.

high-speed operation, the intermediate winding is not connected in the circuit as shown in Fig. 1.23, and line voltage is applied to the main winding and to the auxiliary winding and capacitor in series. For low-speed operation, the intermediate winding is connected in series with the main winding and with the auxiliary circuit as shown in Fig. 1.23. This connection reduces the voltage applied across both the main wind ing and the auxiliary circuit, thus reducing the torque

FIGURE 1.22 Permanent split capacitor single-phase motor with a T-type connection and two-speed operation.

the motor will develop and hence the motor speed to match the load requirements. The amount of speed reduction is a function of the turns ratio between the main and intermediate windings and the speed-torque characteristics of the driven load. It should be recognized that, with this type of motor, the speed change is obtained by letting the motor speed slip down to the required low

FIGURE 1.23 Permanent split capacitor single-phase motor with a T-type connection and a winding arrangement.

speed; it is not a multispeed motor with more than one synchronous speed.

An example of the speed-torque curves for a tapped-winding capacitor motor is shown in Fig. 1.24. The load curve of a typical fan load is superimposed on the motor speed-torque curves to show the speed reduction obtained on the low-speed connection.

FIGURE 1.24 Speed-torque curves for a permanent split capacitor single-phase motor with a tapped winding.