3.1.1

Figure 3.1 illustrates a basic ac motor manufacturing process flow. The first step is producing laminations. These laminations are separated into rotors and stators. The stator laminations, shown in Fig. 3.2, are then stacked into a core, and copper and/or aluminum wire is wound into the core, producing a wound stator core. An outer housing of some type is produced, and that is then wrapped around the wound sta-tor core, making a wound stator assembly. The wound stator assembly is then sent to motor assembly.

FIGURE 3.1 Ac motor manufacturing process flow.

The rotor laminations in Fig. 3.3 are also stacked and then aluminum die cast into a rotor casting, shown in Fig. 3.4. A shaft is then produced, and this is assembled into the rotor, making it a rotor assembly, shown in Fig. 3.5.The rotor assembly is sent to motor assembly.

Two end frames are produced and sent to motor assembly.

At the final operation, the wound stator assembly, rotor assembly, two end frames, and miscellaneous parts are assembled into a complete motor. The motor is then tested, painted, and packed for shipment.

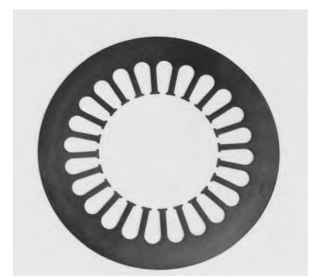

FIGURE 3.2 Stator laminations.

FIGURE 3.3 Rotor laminations.

AC Motor Manufacturing Process Flow (Electric Motors)

Next post: DC Motor Manufacturing Process Flow (Electric Motors)

Previous post: MECHANICS AND MANUFACTURING METHODS (Electric Motors)