For an average family using between 700 and 1200 litres of hot water per week, the energy involved can be a significant proportion of the whole energy budget at around 20 per cent. If a high level of insulation has been achieved the proportion is higher. The most popular heating method is by an electrical immersion heater because of its convenience, safety and low capital cost. At the same time it is the least environmentally acceptable with a high carbon equivalent for every litre of water. Of all the fossil fuels natural gas or methane creates the least carbon emissions. In terms of kilograms of CO2 emitted per gigajoule of delivered energy, gas produces 54 kg and electricity 141.6 kg (Source: Building Research Establishment).

Most homes have hot water storage cylinders and most are inadequately, if at all, insulated. New cylinders come fitted with an insulation jacket. However, this is usually not up to the advised thickness which should be at least 100 mm. This might be somewhat relaxed if the cylinder is in a closed cupboard used for airing clothes. The efficiency can be significantly increased if heat is recovered from the waste hot water. One way is to employ heat pump technology which was explained in topic 7. In the USA and Scandinavia it is becoming increasingly common to exploit the heat recovered from the ventilation system to heat the DHW system. Even in temperate climates there is increasing evidence of solar energy being employed to supplement DHW heating. This will be considered in more detail below.

The alternative to a storage system is the instant point heater. In certain conditions this may be the more economical option. For example, when

• the household consists of one or two persons;

• the number of locations needing hot water is limited;

• simultaneous need for large quantities of hot water is avoided;

• most demand is for small quantities;

• there is no mains gas supply.

This may be a more economical and efficient facility than a storage tank with immersion heater. In small properties it also has the advantage of not requiring a special cupboard.

There is also the option of a gas point heater with a balanced flue. This solves the problem of providing combustion air from the outside whilst eliminating the need for a vertical flue which must have a minimum height to ensure sufficient ‘pull’ on the waste gases – a potential problem in bungalows. However, there are regulations concerning the positioning of balanced flues particularly in relation to the proximity of opening windows.

Solar thermal energy

It is likely that solar thermal power will provide a major share of the renewable energy needed in the future since solar radiation is by far the largest potential renewable resource. About 1 per cent of the earth’s deserts covered with solar thermal plants would have supplied the world’s total energy demand for the year 2000.

Energy from the sun serves two energy domains – heat and electricity.

Solar heating

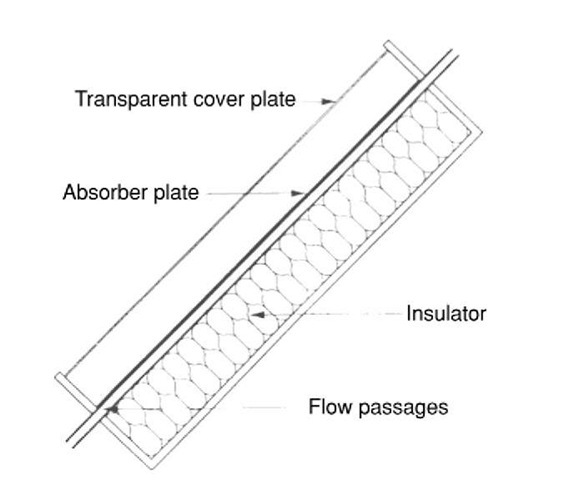

Solar panels have traditionally been associated with providing domestic hot water. Even in temperate climates they offer a useful boost to domestic hot water (DWH) systems. Basically they consist of a circuit of pipes placed on a roof and linked to a DHW cylinder. The most straightforward type is the flat plate collector. This consists of an array of pipes beneath a matt black metal sheet which absorbs solar heat. This, in turn, is protected by a transparent cover. The underside of the pipes is insulated (Figure 8.1).

Figure 8.1 Flat plate solar collector.

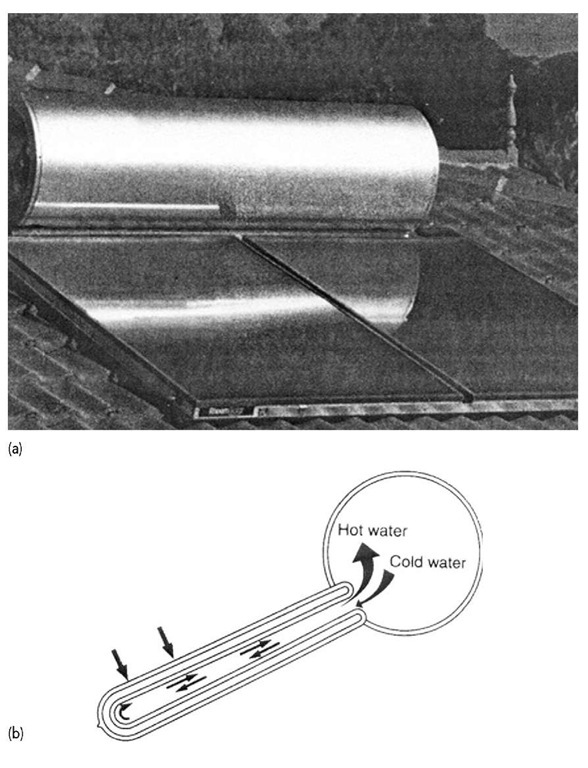

This type of collector achieves a temperature of about 35°C which is useful for pre-heating water for a boiler or immersion heater. This is often referred to as ‘active solar’ due to the fact that the water is pump-driven through the thermal coils. There is an alternative called a thermosyphon system in which circulation of the working fluid is driven by thermal buoyancy. In this case, a storage tank sits at the top of the collector (Figure 8.2).

Figure 8.2 (a) and (b) Flat plate thermosyphon collector with header tank. Source: Courtesy of Renewable Energy World (REW) March-April 2002.

Vacuum tube collectors

In this technology evacuated tubes enclosed within an insulated steel casing work by exploiting the vacuum around the collector. This reduces the heat loss from the system. They can heat water to around 60°C, but sometimes significantly higher. This means that domestic hot water systems may have no need of additional heating. To realize their full potential they should be linked to a storage facility which stores excess warmth in summer to supplement winter heating. This type of solar collector is most efficient in direct solar radiation, but less effective in cloudy or diffuse conditions (Figure 8.3).

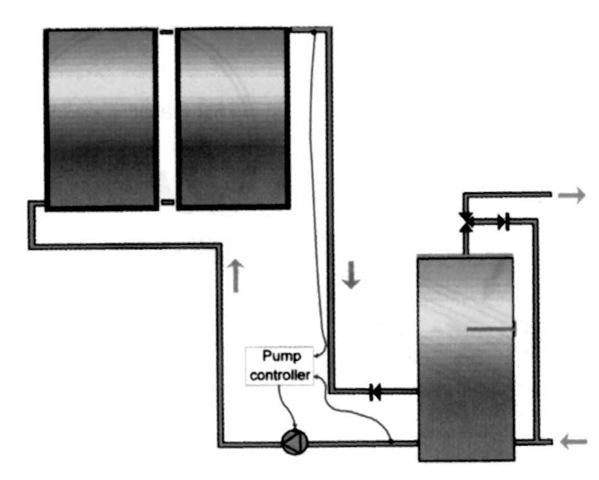

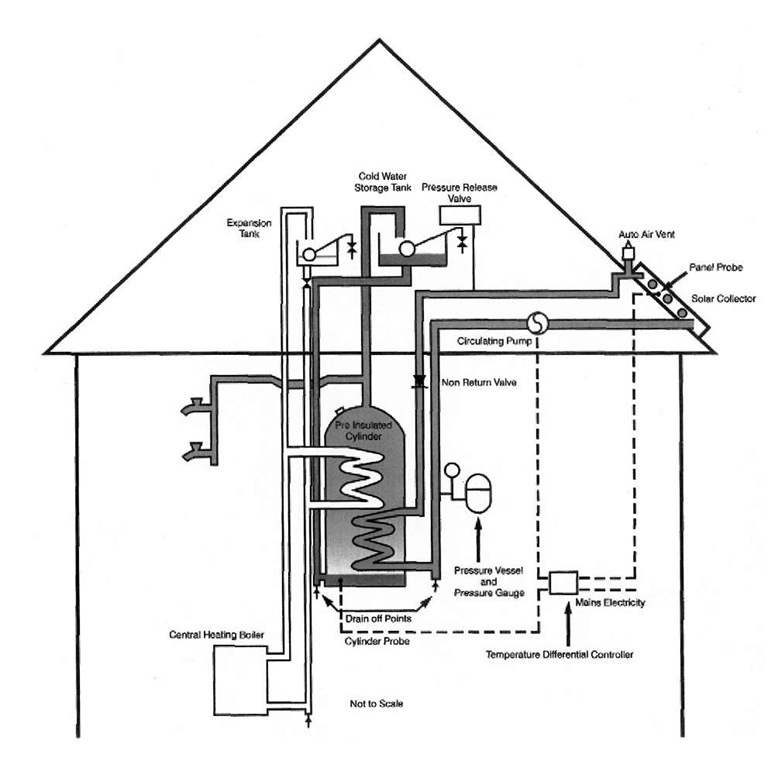

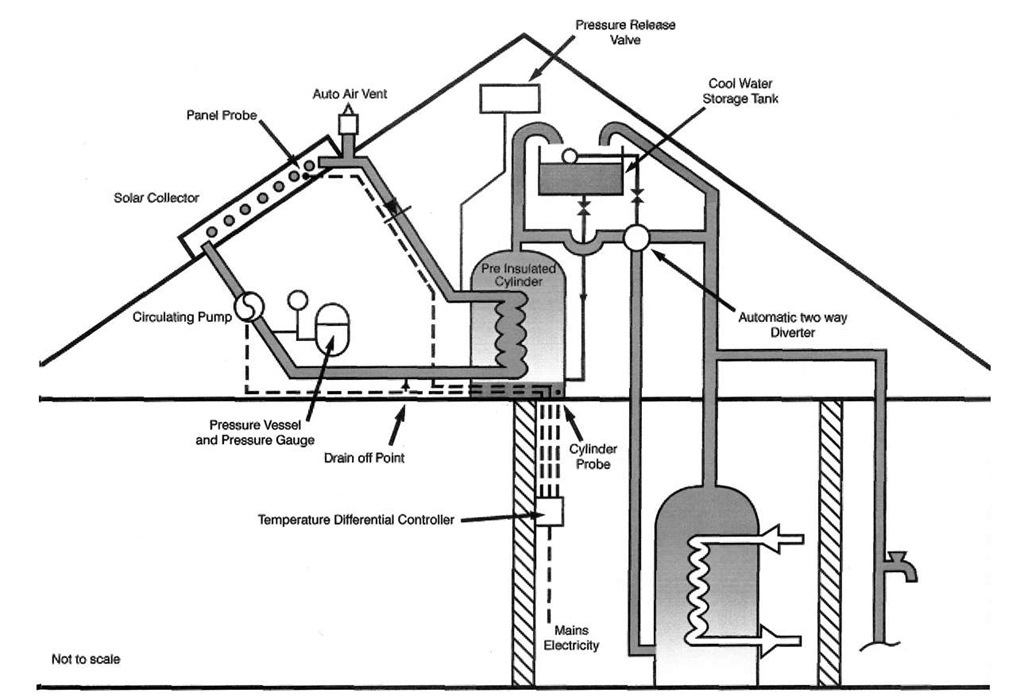

There is a further division into direct or ‘open loop’ systems in which potable water is circulated through the collectors (Figure 8.4) and ‘closed loop’ or indirect systems which use an anti-freeze heat transfer circulating fluid (Figure 8.5).

It is now possible for the collector system to incorporate a photovoltaic module to provide power for the circulating fan, making it a true zero fossil energy option.

Figure 8.3 Vacuum tube solar collectors on Professor Tony Marmont’s Farm, Nottinghamshire.

Figure 8.4 Open loop pumped circulation system.

Figure 8.5 Closed loop (indirect) pumped circulation system with internal coil heat exchanger.

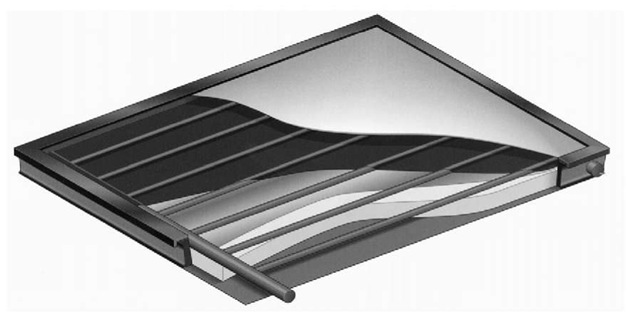

A type of solar collector which is particularly efficient in cloudy conditions is one which employs ‘fin and tube’ technology. The effect of this is to increase the surface area of the absorber pipes by 20 per cent. The absorbers are placed behind 3 mm toughened glass with a backing of foil-backed phenolic foam. At an inspection of a 5.2 m2 installation of this system by the author in January 2003, the air temperature was 6°C and the sky cloudy and dull.

Figure 8.6 Sunuser solar thermal panel.

Figure 8.7 Sunuser retrofitted solar thermal collectors.

The temperature of the water fed from the panels was 21°C. Whilst not exactly warm, this gives an indication of the rate of temperature gain. In this property the space heating is provided by warm air, so the solar collectors are dedicated to providing domestic hot water. Since they were installed the immersion heater has been switched off. The area of the house is approximately 250 m2 occupied by two adults. The overall cost of the installation including VAT, was £5103.00 (Figures 8.6, 8.7 and 8.8).

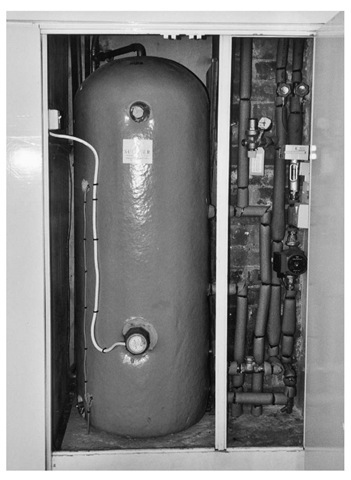

Figure 8.8 Sunuser cylinder and controls.

In more conventional homes with wet central heating systems there are two options: a dual coil system or a twin tank arrangement. The first system allows water to be drawn from the taps with surplus replenishing the hot water cylinder.

With the dual coil arrangement (Figure 8.9) the existing central heating or boiler pipe work is relocated to the upper part of the cylinder, while the solar heated water enters at the lower part. A temperature differential controller measures the difference between the solar panels and the cylinder and activates a pump whenever the temperature in the collectors is greater than that in the cylinder (Figure 8.10).

In Europe, there are wide variations in the application of active solar heating. For example, Austria has almost 18 m2 per 1000 inhabitants of installed capacity compared with the UK which boasts about 0.2 m2. Yet the UK climate is not all that different from that of Austria. There is a big opportunity gap.

Figure 8.9 Sunuser dual coil system.

Figure 8.10 Sunuser twin tank system.