Geoscience Reference

In-Depth Information

added to the spring in one of the extremes (as a

dynamometer) or it is pulled by one of the edges, it will

stretch by the action of the applied force. The bigger the

load, or the more the spring is pulled on the extremes, the

longer it becomes by stretching. When the spring is

released or liberated from the load in one of the extremes

the spring returns to the original length.

Elasticity in rocks is defined by several parameters; the

most commonly used being

Young's modulus

(

E

) and

the

Poisson coefficient

(

value for the Young's modulus means that the level of strain

produced is small for the amount of stress applied, whereas

low values indicate higher deformation levels for a certain

amount of stress. Rigid solids produce high Young's modu-

lus values as they are very reluctant to change shape or vol-

ume. Rigid materials experience

brittle

deformation when

their mechanical resistance is exceeded by the applied stress

level at the elastic boundary.

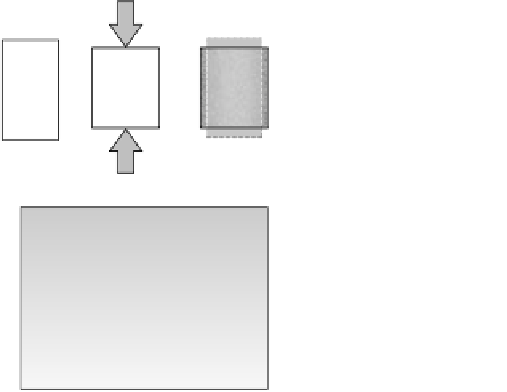

When applying uniaxial compressional tests to rock

samples, vertical shortening may be accompanied by some

horizontal expansion. The Poisson coefficient (

). Young's modulus is a measure of

the resistance to elastic deformation which is reflected in the

linear relation between the stress (

) shows

the relation between the lateral dilation or barreling of a

rock sample and the longitudinal shortening produced by

loading: thus

) and the strain (

):

E

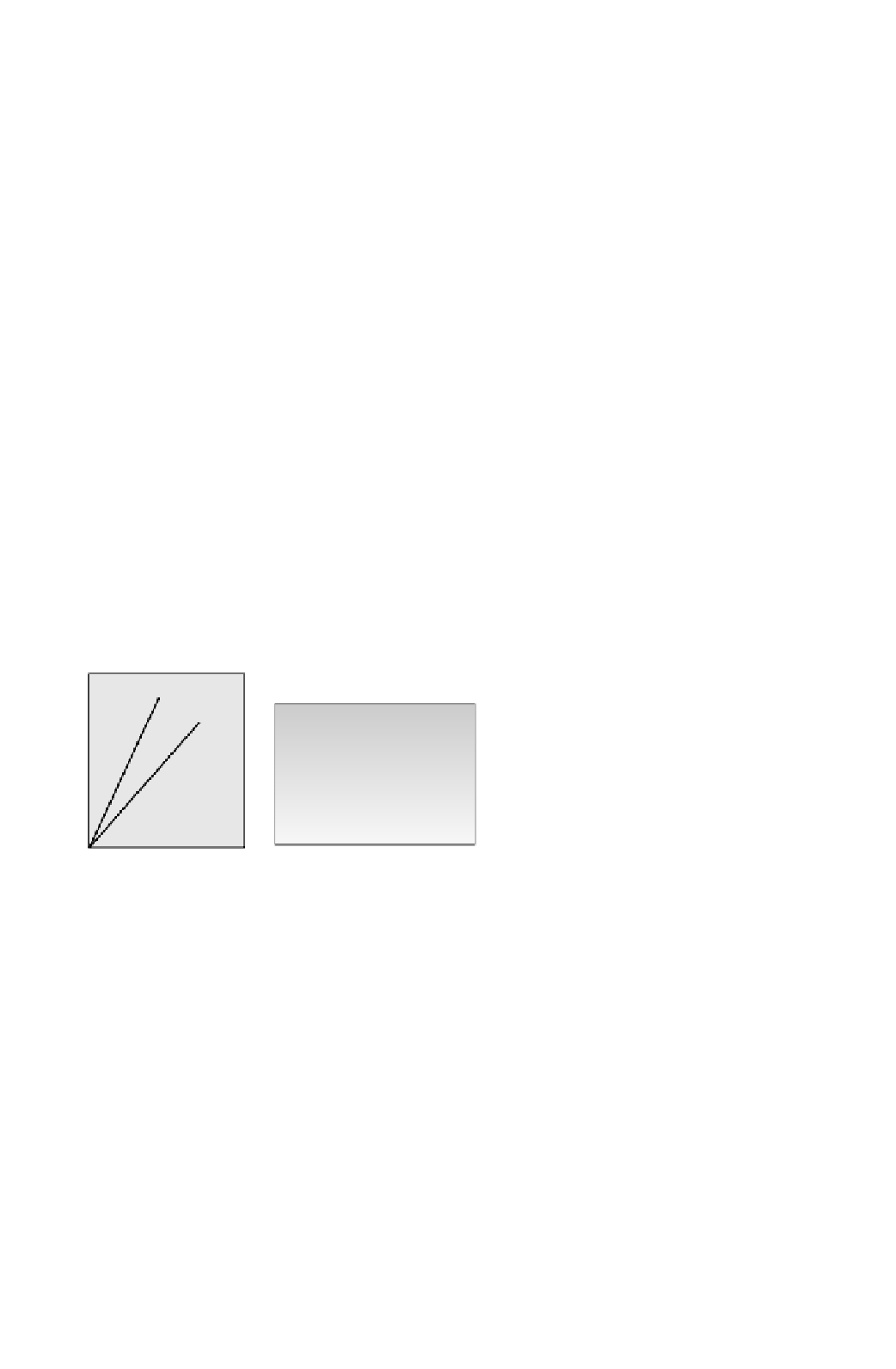

(Fig. 3.93a). This linear relation, which was observed

initially by Hooke in the mid-seventeenth century by apply-

ing tensile stresses to a rod and measuring the extension, is

commonly known as Hooke's Law. Considering that all

parameters used to measure strain (stretch, extension, or

quadratic elongation) are dimensionless, the Young's modu-

lus is measured in stress units (N m

2

, MPa) and has negative

values of the order of

/

longitudinal

and it can be seen that

Poisson's coefficient is dimensionless (Fig. 3.93b). When

stresses are applied, if there is no volume loss, the sample

has to thicken sideways to account for the vertical shorten-

ing. Typically, the sample should develop a barrel form

(nonhomogeneous deformation) or increase its surface

area as it expands laterally. For perfect, incompressible,

isotropic, and homogeneous materials which compensate

the shortening by lateral dilation without volume loss, the

Poisson's coefficient is 0.5; although values for natural

materials are generally smaller (Fig. 3.93b). In very rigid

rock bodies, the lateral expansion may be very limited

or not occur at all; in this case there is a volume loss and

lateral

/

10

5

. The reason why the

values are negative is because the applied stress is extensional

and hence has a negative value, and the strain produced is a

lengthening, which is conventionally considered positive.

Not all rocks follow Hooke's Law; some deviations occur

but they are small enough so a characteristic value of

E

can

be defined for most rock types (Fig. 3.93a). A high absolute

10

4

or

(a)

(b)

Uniaxial

compression

a

Final state

Original

Rock type

E

(10

4

MPa)

ec

c

b

Marble

Limestone

Granite

Shale

Quartzite

Diorite

-4.8

-5.3

-5.6

-6.8

-7.9

-8.4

e

d

d

E

a

>

E

b

n

=

e

d/

e

c

e

(%)

E

=

s

/

e

(Hooke's Law)

Rock type

n

Schist, biotite

Shale, calcareous

Diorite

Granite

Aplite

Siltstone

Dolerite

0.01

0.02

0.05

0.11

0.20

0.25

0.28

Fig. 3.93

Elastic parameters. (a) The Young's modulus describes the slope of the stress/strain straight line, being a measure of the rock

resistance to elastic deformation. Line

a

has a higher value of Young's modulus (

E

a

) being more rigid than line

b

(Young modulus

E

b

)

(i.e. it is less strained for the same stress values); (b) Poisson's coefficient relates the proportion in which the rock deforms laterally when it is

compressed vertically. Comparing the original and final lengths before and after deformation strain

can be calculated and the Poisson's ratio

established.

Search WWH ::

Custom Search