Geoscience Reference

In-Depth Information

cylindrical rock samples. Both tensional (the sample is gen-

erally pulled along the long axis) and compressive (sample

is pushed down the long axis) stresses can be applied, both

in laterally confined (axial or triaxial tests) or unconfined

conditions (uniaxial texts). Experiments involving the

application of a constant load to a rock sample and observ-

ing changes in strain with time are called

creep tests

.

Experimental results are analyzed graphically by plotting

stress, (

3.15.2

Elastic model

Elastic deformation

is characterized by a linear relationship

in stress-strain space. This means that the relation between

the applied stress and the strain produced is proportional

(Fig. 3.91a). An instantaneous applied stress is followed

instantly by a certain level of strain. The larger the stress

the larger the strain, up to a point at which the rock can be

distorted no further and it breaks. This limit is called the

elastic boundary and represents the maximum stress that

the rock can suffer before fracturing. If the stress is

released before reaching the elastic limit such that no frac-

tures are produced, elastic deformation disappears. In

other words, elastic strained bodies recover their original

shape when forces are no longer applied. The classical ana-

log model is a spring (Fig. 3.92a). The spring at repose

represents the nondeformed elastic object. When a load is

/d

t

), the

latter obtained by dividing the strain by time (Fig. 3.91).

Simple mathematical models can be developed for different

regimes of rheological behavior. Stress is usually repre-

sented as the differential stress (

), against strain, (

), or strain rate (d

1

3

). Other important

variables are lithology, temperature, confining pressure,

and the presence of fluids in the interstitial pores

causing

pore fluid pressures

. There are three different pure

rheological behavioral regimes:

elastic, plastic

, and

viscous

(Fig. 3.91). Elastic and plastic are characteristic of solids

whereas viscous behavior is characteristic of fluids. Solids

under certain conditions, for example, under the effect of

permanent stresses, can behave in a viscous way. Elastic,

plastic, and viscous are end members of a more complex

suite of behaviors. Several combinations are possible, such

as

visco-elastic, elastic-plastic

, and so on.

(a)

(a)

Elastic

(b)

Viscous

(b)

h

t

d

e

/d

t

=

E=

s

/

e

Strain rate d

e

/d

t

Strain (

e

)

Object is static

(c)

Plastic

(c)

s

<

s

y

s

y

s

>

s

y

Object moves

Strain (

e

)

Fig. 3.91

Strain/stress diagrams for different rheological behaviors.

(a) Elastic solids show linear relations. The slope of the straight line

is the Young's modulus; (b) viscous behavior is characteristic of flu-

ids. Fluids deform continuously at a constant rate for a certain stress

value. The slope of the line is the viscosity (

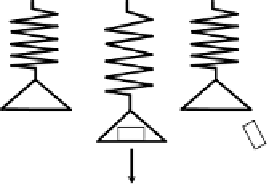

Fig. 3.92

Classical analogical models for (a) elastic behavior, is

compared to a spring; (b) viscous behavior is compared to a

hydraulic piston or dashpots; and (c) plastic behavior, like moving

a load by a flat surface with an initial resistance to slide.

); (c) plastics will not

deform under a critical stress value or yield stress (

y

).

Search WWH ::

Custom Search