Environmental Engineering Reference

In-Depth Information

crude oil is used for transportation (in engines that waste 2/3 of the energy

reliable transportation in modern life has allowed this energy cost to be

accommodated. The 8-9% investment in fossil fuels provides an incredibly

wide range of useful items that we simply cannot avoid coming into contact

with in our daily lives. Plastics in some instances (such as in residential

insulation or aircraft construction) save energy and in applications such as

wind turbines even help generate green energy. The reader is invited to

review some of these benefits in

Chapter 5

.

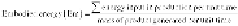

Embodied energy (EE) in a material or product is all the energy directly or

indirectly used in the creation of a unit mass (for instance, a metric ton)

of it. This would include the energy used in extraction of raw materials,

their transportation to a plant, processing in the plant, and maintenance

conditions used in the definition and the mix of energy used (therefore

the location of manufacture). When it is taken to mean all energy from

extraction of raw materials until the product leaves the manufacturer's

location, it is called “cradle-to-gate” energy or the “front-end” energy

investment in producing the material. It does not include the energy cost

of using and disposal of the material or product. The values of EE reported

vary because of how the quantity is calculated;

One criterion in sustainable material selection is to select one with the least

EE that also meets the performance requirements for a given application.

When the raw material itself is an energetic material (such as oil, coal, or

gas) with fuel value, EE also includes the raw-material energy in addition to

the energy expended in manufacturing and transportation. The EE referred

to here is that associated with converting feedstock materials into plastic

resin pellets and not that associated with manufacturing a product. In a

subsequent step where the resin pellets are converted into a product such as

a bottle or a bag, additional energy has to be expended. This latter energy

will be referred to as “process energy,” for clarity.

Although minimizing the EE is a sustainable strategy, at least two other

factors must be taken into consideration: (1) the complete service life of the

material and (2) energy cost per functional unit of the material. There are