Biomedical Engineering Reference

In-Depth Information

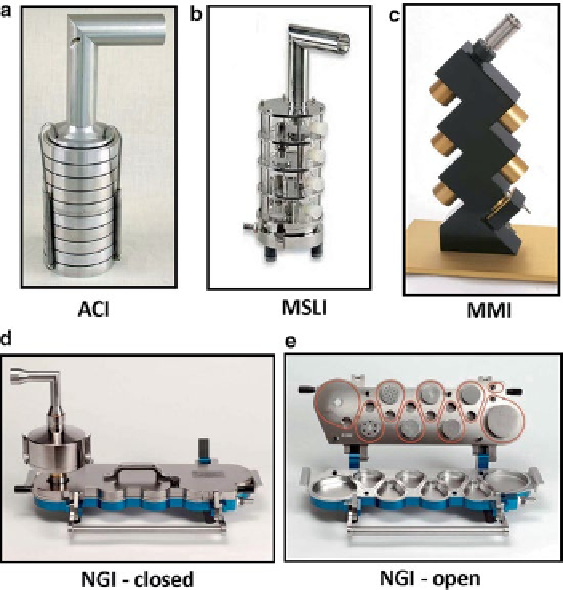

Fig. 2.8

External appearance of the (

a

) ACI, (

b

) MSLI, (

c

) MMI, and (

d

) and (

e

) NGI

In the designs of the ACI (Fig.

2.8a

), MSLI (Fig.

2.8b

), and MMI (Fig.

2.8c

)

systems, the individual impaction stages are connected together in a more-or-less

vertical alignment. It is notable, however, that the NGI has all of its stages located

adjacent to each other in the horizontal plane (Fig.

2.8d, e

). This configuration was

chosen primarily for ease of use for semi- or fully automated operation.

The function of a multistage CI is primarily to fractionate the incoming aerosol

into progressively finer particle sizes, beginning with the coarsest particles. The

linear air velocity,

U

, is therefore increased in a series of well-defined steps as the

aerosol particles move from one stage to the next throughout the sequence. These

increases are put into effect primarily by reductions in the nozzle diameter (

W

) from

one stage to the next in the series. However, the number of nozzles per stage (

n

) as

well as the number of stages within the CI can also be adjusted to optimize size

resolution and minimize pressure drop across especially the stages that size separate

the finest subfractions. It is important to note that inserting more than five stages per

decade of particle size is counterproductive with this technology, because the

stage(s) immediately before a given stage will interfere with efficient particle col-

lection, due to the nonideal nature of their collection efficiency curves. This practical

Search WWH ::

Custom Search