Biomedical Engineering Reference

In-Depth Information

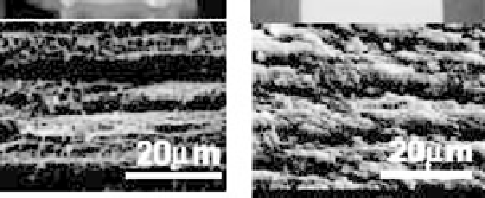

Figure9.13

LayeredstructureofBC(left)andBC/gelatincomposite(right)(39).(Nakayama,

A.; Kakugo, A.; Gong, J.P. etal., High mechanical strength double-network hydrogel with

bacterial cellulose. Advanced Functional Materials, 2004, 14(11), 1124-8. Copyright John

Wiley&Sons-VCHVerlagGmbH&Co.KGaA.Reproducedwithpermission.)

biomedical applications. To remedy this disadvantage, Nakayama

et al

. have immersed

a purified BC pellicle in a gelatin solution after which it was chemically crosslinked

to various crosslinking densities (39). The resulting double networks (DN) combined

the outstanding tensile properties of BC with very high compressive strength. The DN

showed a stratified structure similar to that of BC, consisting of dense and sparse layers

of cellulose fibers (Figure 9.13). The gelatin did not affect the crystalline structure of

BC and was proposed to fill in the cellulose-poor layers. The improvement in properties

imparted by the combination of these two polymers was outstanding. In the direct

ion perpendicular to the stratified structure of the DN, the compressive modulus was

1.7 MPa, that is over 200 times higher than that of BC alone (Figure 9.14). The fracture

strength of the BC/gelatin network was also very largely improved compared to that of

the gelatin gel alone, being 30 times higher. Furthermore the BC/gelatin hydrogel was

capable of recovery after a first compressive deformation up to 30% strain which was

not the case of neat BC. The authors proposed that in the DN gel, mechanical properties

are mainly dominated by the degree of crosslinking of the gelatin and by the unit ratio

of the second network to the first network (R

amino acid/glucose) (Figure 9.14). As

a result the DN could achieve properties similar to that of articular cartilage.

A recent study also evaluated composites of silk fibroin and BC in the dry and in the

wet state (40). Silk protein, a mixture of glycine, alanine and serine, can take various

conformations, amorphous and crystalline, and has generated interest in the biomedical

field as membranes due to its biocompatibility, permeability in the wet state and high

mechanical properties. The authors therefore prepared BC/silk fibroin nanocomposites

by immersing a purified and never dried bacterial cellulose pellicle into aqueous silk

fibroin solution (8 wt%) produced from Bombix mori cocoons and by then drying the

nanocomposites into films. Field emission scanning electron microscopy (FESEM) of

fracture surfaces suggested that the silk protein was finely dispersed between the cel-

lulose fibers resulting in well dispersed nanocomposites. Concomitantly, the fibroin

morphology changed from a mostly amorphous coil structure to a crystalline structure

as a

β

-sheet structure as demonstrated by X-ray diffraction and FTIR spectroscopy. As

a result the mechanical properties of the nanocomposites differed from those of the pure

fibroin or bacterial cellulose films. In the dry state, the tensile modulus of the composite

film (465

=

±

57 MPa) was higher than that of the neat BC film (118

±

9 MPa) or silk

Search WWH ::

Custom Search