Biomedical Engineering Reference

In-Depth Information

10

1

6.0

6.0

BC-Gelatin

5.0

5.0

10

0

4.0

4.0

Gelatin

3.1

10

−

1

3.0

3.0

3.6

2.0

2.0

10

−

2

5.8

BC

1.0

1.0

11

10

−

3

0.0

0.0

0.0

0.2

EDC concentration [M]

0.4

0.6

0.8

1.0

1.2

0

15 20

Amino Acid/Glucose [unit/unit]

5

10

(a)

(b)

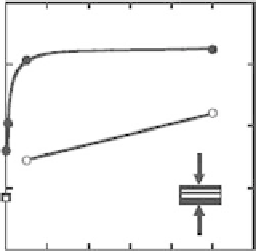

Figure 9.14

Compressive modulus of a BC/gelatin composite as a function of crosslinker

density(a)andofnetworkunitratio(b)(39).(Nakayama,A.;Kakugo,A.;Gong,J.P.etal.,High

mechanicalstrengthdouble-networkhydrogelwithbacterialcellulose.Advanced Functional

Materials, 2004, 14(11), 1124-8. Copyright JohnWiley &Sons-VCHVerlagGmbH&Co.

KGaA.Reproducedwithpermission.)

fibroin film (355

56 MPa). However the composite films were more brittle than the

silk fibroin film with an elongation at break of only 2% and a tensile strength (9

.

4

±

±

1

.

2

MPa) slightly lower than that of the pure silk fibroin film (11

.

5

3

.

3MPa). Onthe

other hand, in the hydrated state, the composite was tougher and more flexible with an

elongation at break reaching 13

.

5

±

2

.

9% but exhibited very low tensile strength and

modulus. Besides the crystallization of the silk into the cellulose fiber mats appeared to

impart a high water resistance to the composite (40).

Solvent casted BC network/thermoplastic nanocomposites have also been developed

using cellulose acetate butyrate (CAB) as the matrix (26). BC/CAB nanocomposites were

prepared by impregnating an unpurified BC sheet into various CAB acetone solutions

and solvent casting such that a 10.3% (Composite A) and a 32% (composite B) volume

fraction BC nanocomposites were obtained. The tensile properties of the composites were

evaluated in static and cyclic modes and the fracture surfaces examined with SEM. The

stress-strain curves revealed an initial linear behavior followed by a yielding at a strain

of 0.6-0.8% and second linear region for strains higher than 2% (Figure 9.15). While the

strain at the maximum load was similar for the two composites at ca 3.5%, the Young

modulus and the tensile strength of BC/CAB nanocomposites improved significantly

with higher BC content. Tensile stiffness and strength more than doubled with ca 10%

addition of BC from 25.9 MPa and 1.2 GPa to 52.6 MPa and 3.2 GPa, respectively.

With 32% addition of BC, tensile stiffness and strength increased approximately 5 folds

to 128.9 MPa and 5.8 GPa. However the nanocomposites never reached the tensile

stiffness and strength of control BC films at 260 MPa and 15-18 GPa, respectively (9).

The cyclic test showed that in a loading cycle the unloading modulus was systematically

higher than the loading modulus and that the elastic moduli systematically increased

with each successive loading/unloading cycle, suggesting reorientation and slippage of

±

Search WWH ::

Custom Search