Chemistry Reference

In-Depth Information

within the channel mainly due to their hydrodynamic drag in the surrounding oil

phase. Contact between adjacent droplets was not desired, in an effort to keep droplet

coalescence and other cross-talk effects to a minimum.

The situation becomes completely different if the volume fraction of the oil phase

is reduced such that droplets maintain mutual contact throughout. The transport of

the droplets in the device is then not anymore determined by the streamlines of the

oil phase, but by the (dynamically varying) geometry of optimum packing of the

droplets within the channel geometry [

12

,

16

]. In fact, the arrangement of spherical

droplets has been reported to change from random to crystalline as their volume

fraction becomes large. In a square channel with a lateral dimension of about four

droplet diameters, a volume fraction of 0.75 shows a crystalline order, while a random

arrangement is observed at 0.55 [

12

].

It is clear that this opens up qualitatively new possibilities of droplet manipulation.

In particular, the existence of several meta-stable configurations gives rise to strong

hysteresis effects in the droplet geometry. Droplet motion may thus not be reversible,

and become strongly history dependent. If the droplets are all of the same size, i.e.,

if a mono-disperse gel emulsion is used, these effects can in principle be exploited

to dynamically access a large variety of droplet configurations in the device [

10

,

11

,

17

,

18

]. Furthermore, these configurations are geometrically rather stable, because

the wetting forces determining the angles of contact of the oil lamellae spanning

between the droplets, give rise to substantial energy barriers for any spontaneous

rearrangement.

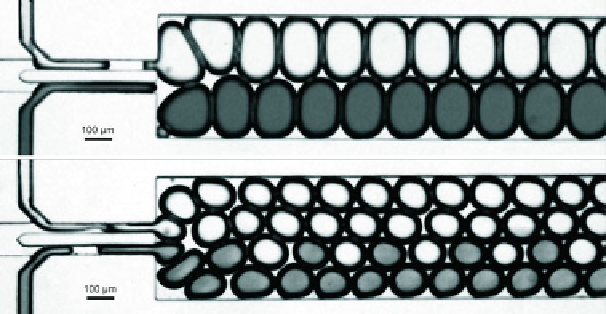

A simple example is displayed in Fig.

2.3

, which shows regular configurations of

droplets with different content. We used squalane with 15mg/ml of 1,2-diphytanoyl-

sn-glycero-3-phosphocholine (DPhyPC, Avanti Polar Lipids) plus 15mg/ml of

cholesterol as the oil phase, which enters the emulsification unit [

13

] from the left.

Fig. 2.3

Gel emulsions of water in oil generated by step emulsification, forming rafts in a wider

channel. The channel width is 500

m, the volume fraction of the aqueous phase is 0.75. The elemen-

tary cells of such rafts can be quite complex, as the lower example shows. Controlled rearrangement

of these configurations are possible by appropriately chosen channel geometries [

12

,

18

,

20

]

µ