Environmental Engineering Reference

In-Depth Information

10.1.2.1 Electrocaloric Ceramic Materials

Ceramic materials exhibiting the electrocaloric effect can be, based on their

thickness, divided into bulk ceramics (with a thickness greater than 100

µ

m), thick-

lm ceramics (with a thickness of a few tens of micrometres) and thin-

lm ceramics

(with a thickness of less than 1

µ

m). Such a classi

cation is also common in other

areas where electroceramics are used [

14

].

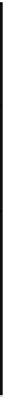

The adiabatic temperature change in bulk ceramics is usually of the order of a

few kelvins, as can be seen from Table

10.1

. The highest adiabatic temperature

change of a bulk ceramic material known to the authors of this topic was 4.5 K for

the Ba(Zr

0.2

Ti

0.8

)O

3

(BZT) ceramic [

15

].

Thick-

100 times thinner than bulk ceramics. In

most cases they are in the form of a multilayer structure, also known as a multilayer

capacitor. The largest electrocaloric effect in a multilayer capacitor was reported by

Bai et al. [

24

]. They measured an adiabatic temperature change of 7.1 K in a multi-

layer capacitor constructed from 63 layers of 3-

lm ceramics are, in general, 10

-

m-thick BaTiO

3

. Kar-Narayan et al.

[

25

,

26

] measured the adiabatic temperature change of a very similar, commercially

available, multilayer structure; however, they reported an adiabatic temperature

change of 0.5 K. Furthermore, Kar-Narayna et al. [

27

] analysed the cooling powers

achievable withmultilayer capacitors. Based on theoretical estimations they predicted

that an idealized electrocaloric cooling device with multilayer capacitors could

achieve a speci

ʼ

c cooling power up to 2,875 Wkg

−

1

. One of the few cases where the

electrocaloric effect was measured in a thick-

lm ceramic that was not in the form of a

multilayer capacitor was reported by Ro

ž

i

č

et al. [

12

]. They measured an adiabatic

temperature change of 1.8 K in a 28-

ʼ

m-thick PLZT 8/65/35 ceramic

lm. The

electrocaloric properties of some thick-

lm ceramics are collected in Table

10.2

.

Table 10.1 Electrocaloric properties of bulk ceramics

Material

a

(K)

Δ

E (MVm

−

1

) q

r,max

(Jkg

−

1

)

Δ

T

ad

(K)

Δ

s

is

(Jkg

−

1

K

−

1

)

T

ref

Measurement

procedure

References

BNT-0.3BT

2.1

/

423

5

/

Indirect

[

16

]

−

BNT-KN

1.73 /

349

1.7

/

Indirect

[

17

]

BZT (x = 0.2)

4.5

8

312

14.5

2,478 Direct

[

15

]

BZT (x = 0.15)

4.2

7.3

342

15

2,481 Direct

[

15

]

NBT

−

0.34

−

0.43

413

5

176

Indirect

[

18

]

NBT-0.08BT

0.19 0.26

370

4

96

Indirect

[

18

]

PLZT 8/65/35

2.2

/

385

8.8

/

Direct

[

19

]

PMN

2.6

/

451

9

/

Direct

[

12

]

PMN

0.11 /

274

1

/

Indirect

[

20

]

PMN-0.85PT

1.7

/

291

1.6

/

Direct

[

21

]

PMN-0.3PT

2.7

/

429

9

/

Direct

[

19

]

PMN-0.08PT

1.3

/

296

1.5

/

Direct

[

22

]

PZN-0.08PT

0.25 /

453 1.2

/

Direct

[

23

]

a

T

ref

—

temperature at which

Δ

T

ad

,

Δ

s

is

and q

r,max

were obtained

Search WWH ::

Custom Search