Graphics Programs Reference

In-Depth Information

Step 12: Create a Drilling Program

Goal

: To estimate the number and direction of drill holes.

Input

: SketchUp model.

Tool

: SketchUp Pro.

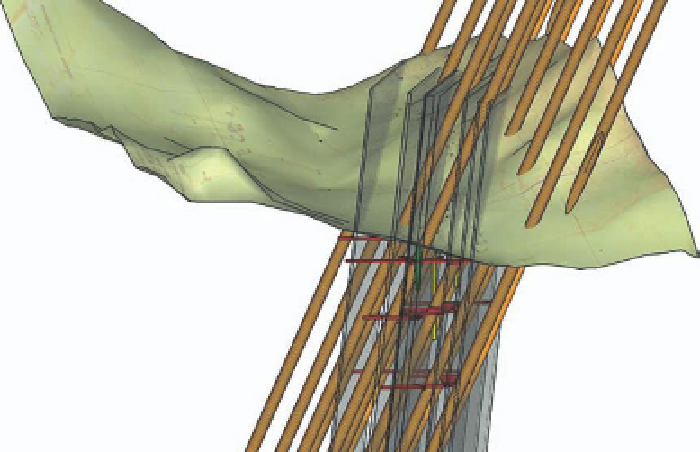

To evaluate a potential resource, the best method is to design a drilling

program to sample the minerals. From the narrative of mineral thickness, I

created a set of parallel polygons using the Move/Copy tool and VCB, and the

layers were rotated with the Rotate tool to the correct angle and then rotated

again to the correct direction to represent the mineral layers. The drilling engi-

neer recommended an 80-m drilling grid, parallel to the mineral layers, and

at approximately 60-degree inclination to intersect the minerals. One of the

biggest risks is to intersect an existing mine shaft or tunnel as the drill can get

stuck, causing significant loss of time and equipment. To minimize the risk of

intersecting the mine tunnels, the grid of wells was shifted until no intersec-

tions were visualized using section cuts.

FiG 15.21

Note that Intersect with mode was not successful at identifying which drill

holes intersected a tunnel.

Step 13: Pit Volume Estimation

Goal

: To estimate the open cut volume for the site.

Inputs

: SketchUp model and slope stability angle.

Tools

: ArcGIS, SketchUp Pro, and VolumeCalculator21 plug-in.

The lowest cost method of mining is to create a pit; so, using an engineer-

supplied stable slope angle, I used ArcGIS to create a set of pit contours,

imported these to SketchUp, and used Sandbox to create a generic pit. Using

Search WWH ::

Custom Search