Biomedical Engineering Reference

In-Depth Information

8.7

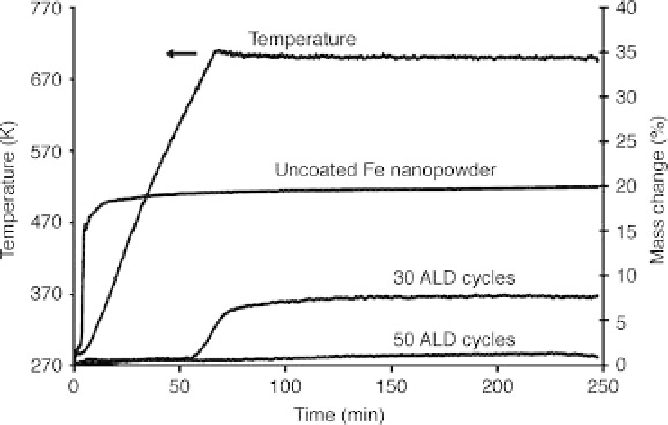

TGA plot of the thermal stability of uncoated and alumina-coated

Fe nanoparticles at elevated temperatures in the presence of air (Hakim

et al

., 2007). Reproduced by permission of IOP Publishing.

8.4

Enhanced lithium-ion batteries using ultra-thin

ceramic films

Lithium ion (Li-ion) batteries are believed to be quite promising to store

energy for vehicles because of their high energy-to-weight ratios (Sun et al.,

2005, 2009; Carpenter et al., 2008). In order to employ Li-ion battery

technologies in next-generation hybrid electric and/or plug-in hybrid electric

vehicles (HEVs and PHEVs), these batteries must satisfy many require-

ments. Examples of the near-term needs that will help bring Li-ion battery

technologies to market include electrodes fabricated from inexpensive

environmentally benign materials with long lifetimes (near-term targets are

5000 charge-depleting cycles, 15-year calendar life), stability over a wide

temperature range (from

C), a high energy density, and a

high rate capability (Jung et al., 2010b). Current efforts include the

development of low-cost electrode materials, better electrolytes, and low-

cost packaging for such batteries. One effective path to cost reduction is to

improve power capability and extend battery life, thereby reducing the

overbuilding of Li-ion batteries while maintaining an energy density suitable

for transportation applications (Chen et al., 2010). Thin film coatings on Li-

ion battery electrode powders have proven to be an effective way to improve

the capacity retention, rate capability, and even the thermal stability of

cathode materials. Different coating materials have been studied, including

carbon (Chen and Dahn, 2002; Belharouak et al., 2005; Cao et al., 2007),

metal oxides (e.g. Al

2

O

3

,ZrO

2

, ZnO, SiO

2

, and TiO

2

) (Cho et al., 2001; Li

et al., 2006) and metal phosphates (e.g. AlPO

4

) (Cho et al., 2003).

46

8

C to +66

8