Biomedical Engineering Reference

In-Depth Information

8.6

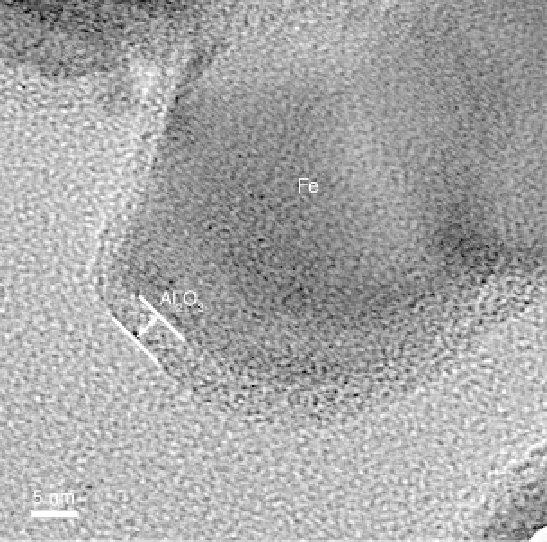

Example of cross-sectional HRTEM analysis of alumina-coated iron

nanoparticles (Hakim et al., 2007). Reproduced by permission of IOP

Publishing.

temperature-dependent oxidation behavior of uncoated Fe nanopowder and

the oxidation resistance of Fe nanopowder coated by 30 and 50 cycles of

Al

2

O

3

ALD is shown in Fig. 8.7. It is clear that the Fe nanopowder began to

oxidize almost instantaneously in air, and resulted in a mass gain of 20% at

a temperature of 250

6 nm film thickness), the

onset of oxidation was delayed until a temperature of approximately 350

8

C. For the 30 cycle film (

~

C.

The 10 nm film (50 cycles) showed no signs of oxidation when held at a

temperature of 400

8

C for over three hours. The resulting elemental analyses

from these experiments showed that the oxygen content of the 50 cycle

material matched the anticipated content for Al

2

O

3

coated on iron metal,

not an oxidized form. Similar results have been obtained for Al

2

O

3

ALD

films coated on the other core metals produced from the decomposition of

their respective oxalates. However, at much higher temperatures, the

mismatch between thermal expansion coefficients of the core and shell is too

great and the passivating layers may be fractured. This problem can be

overcome by depositing alternating multilayers of materials to perform

thermal expansion matching between the composite film and the core

particle. The magnetic moment of the micron-sized iron spheres coated by

various thicknesses of Al

2

O

3

remained unchanged, which was anticipated

due to the extreme thinness of each shell (Hakim et al., 2007).

8