Biomedical Engineering Reference

In-Depth Information

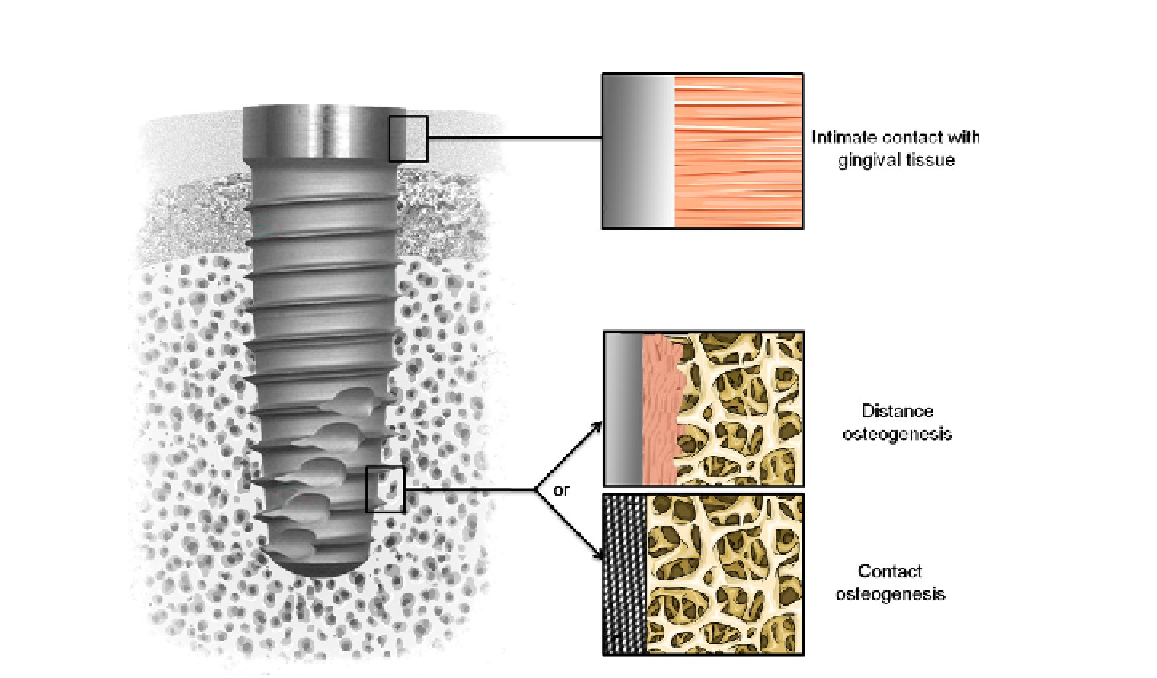

FIGURE 5.1

Tissue integration of dental implant. Note the intimate contact with gingival tissue in the upper part and the

desired contact osteogenesis in the tapered lower part rather than distance osteogenesis.

composition, wettability, and roughness of metal implants surfaces. However, the control of these sur-

face properties at the protein and cell levels, thus in the nanometer range, remains a challenge for

researchers and dental implants manufacturers.

Nanotechnologies may produce surfaces with controlled topography and chemistry that would help

understanding biological interactions and developing novel implant surfaces with predictable tissue-

integrative properties

[2-4]

. Various processing methods derived from the electronic industry such as

lithography, ionic implantation, anodization, radio-frequency plasma treatments may be applied to the

surfaces of dental implants to produce controlled features at the nanometer scale. These surfaces may

then be screened by using high-throughput biological assays

in vitro

. For instance, specific protein

adsorption, cell adhesion, and differentiation of stem cells should be studied in relation to the surface

properties. This approach may define the ideal surface for a specific biological response. Following

in vitro

screening, nanostructured surfaces may then be tested in animal models to validate hypothesis

in a complex

in vivo

environment.

New coating technologies have also been developed for applying hydroxyapatite (HA) and related

calcium phosphates (CaP), the mineral of bone, onto the surface of implants (

Figure 5.2

). Many