Graphics Programs Reference

In-Depth Information

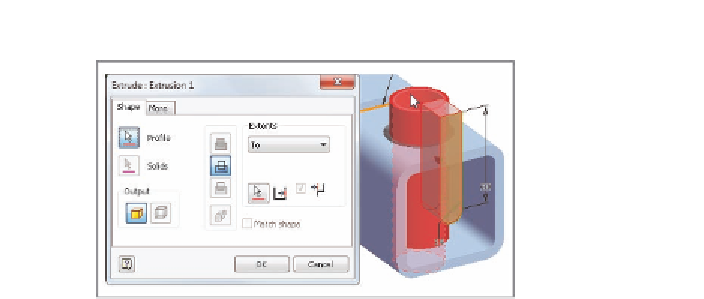

FIGURE 12.11

A preview of the intermittent fillet weld

Like preparation features, the cuts made by the extrusion do not appear in the

source files. They remove the original component geometry and the geometry

created by the welds themselves.

Documenting Welds and Weldments

Inventor keeps track of the physical properties of the welds as they're added. It

also keeps track of the various states of the model so that the preparation, welds,

and machining geometry can be documented as a workflow.

Extracting the Physical Properties of the Beads

To help estimate the materials needed to create a weldment, you have the BOM

for the components, but you also need the volume and mass of the weld beads.

1.

Make certain that the 2013 Essentials project file is active, and then

open

c12-08.iam

from the

Assemblies\Chapter12

folder.

2.

Expand the Welds category in the browser, and right-click the Beads

folder.

3.

Select iProperties from the context menu.

4.

Switch to the Physical tab, and click Update to get the mass and volume

information on the weld material for the assembly. See Figure 12.12.

You can also get the properties for individual beads by generating a

bead report.

5.

Close the iProperties dialog, and click the Bead Report tool from the

Weld panel on the Weld tab.

6.

When the weld bead report is opened, click Next.

7.

Choose a name and destination for the XLS file. Figure 12.13 shows

an example.

Search WWH ::

Custom Search