Environmental Engineering Reference

In-Depth Information

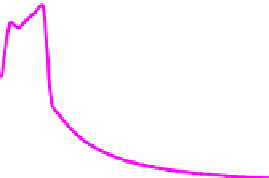

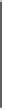

The values of engine maximum LFG flow rate and energy conversion efficiency were

retrieved from Jenbacher engine technical forms. Energy conversion efficiency was

considered dependant on the engine load (i.e. decreasing when load decreases) according to

the indications on Jenbacher engine technical forms.

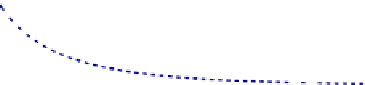

On the basis of the LFG collected yearly, obtained from the Scholl Canyon model, it is

possible to estimate the appropriate size and number of reciprocating engines required every

year for the LFG exploitation, considering as constraints the maximum load (i.e. maximum

LFG flow rate) for each engine and 90.000 hours as maximum amount of operating hours for

each engine (about ten years).

As a matter of fact, during the energy recovery time, different combinations of engine

sizes and numbers can be adopted to exploit the LFG: the selection of the final combination,

was carried out with the aim of maximising the profits coming from the balance of energy

system investment and maintenance costs and electric energy selling earnings.

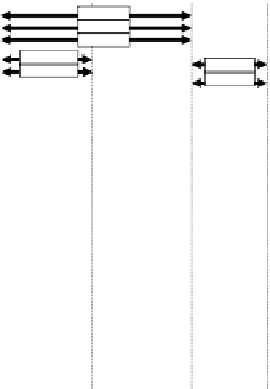

Assuming the energy recovery to start at the sixth year of landfill operation and to finish

in year thirty-eight, a combination of engines which maximises the profit was found, based on

the use of one 143 kWe engine, three 625 kWe engines and two 1413 kWe engines,

distributed as shown in Figure 10.

3,00E+07

625 kWe

625 kWe

625 kWe

1413 kWe

1413 kWe

143 kWe

143 kWe

2,50E+07

2,00E+07

1,50E+07

1,00E+07

5,00E+06

0,00E+00

1

6

11

16

21

26

31

36

41

46

51

56

61

66

71

76

81

Year

Recovered EE [kWh]

Produced LFG [Nm3]

Collected LFG [Nm3]

Figure 10. Results of produced LFG, collected LFG and recovered electric energy, with the indication

of the time during which engines have been used.

The economic evaluation was carried out considering the depreciation annual cost for the

engine investment (considering 6,5% interest rate and 10 years investment time), the

maintenance costs (assumed 0,03 €/kWh for programmed maintenance plus 3% for non

programmed maintenance), the earnings for electric energy (EE) selling assuming a selling

price equal to 0,13 €/kWh (considering an engine availability of 88%). Table 7 reports the

engine costs. Results in terms of produced EE, overall costs and earnings are reported in

Table 8.