Environmental Engineering Reference

In-Depth Information

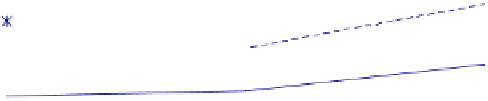

2,50E+07

2,00E+07

1,50E+07

1,00E+07

5,00E+06

0,00E+00

5

6

7

Year

Measured collected landfill gas

Scholl Canyon - collected

Triangular - collected

Modified first order - collected

LandGEM - collected

Figure 9. Comparison of results obtained from the different applied models with the data of collected

LFG.

6.

E

NERGY

R

ECOVERY

The selected Scholl Canyon model has been used to predict the LFG production for the

case-study landfill in order to properly size the energy recovery system along the time. In

particular, reciprocating engines were considered for energy recovery purpose. The LFG

energy recovery by means of reciprocating engines is a quite wide spread practice in modern

landfills, but the energy recovery system definition and sizing, also in reference to its

economic convenience, is a crucial and tricky issue.

For this reason, the selection of the engine configuration along the time has been carried

out with the aim of obtaining the maximum profits from selling the produced electric energy.

It has been assumed that no LFG collection takes place until the fifth year included, then

the assumed collection efficiency coefficient is equal to 40% for the sixth and seventh years,

and 60% for the following years (on the basis of the designed improved collection network in

the specific plant).

Several sizes of engine have been considered with reference to existing Jenbacher

engines (kWe 143, kWe 330, kWe 511, kWe 625, kWe 836, kWe 1048, kWe 1413, kWe

1698). The amount of potential electric energy has been calculated according to:

(12)

EE

=η

⋅

LHV

⋅

V

el

LFG

LFG

where:

EE = electric energy [kW]

η

el

= engine electric energy conversion efficiency

V

LFG

= LFG flow rate [Nm

3

/h]

LHV

LFG

= LFG low heating value [kWh/Nm

3

]