Environmental Engineering Reference

In-Depth Information

experiments where hydrogen was produced from paper sludge in supercritical water in the

presence of ruthenium (IV) dioxide, RuO

2

. The reaction conditions were 100 mg paper

sludge, 20 mg catalyst, temperature of 450

o

C for 2 hours. The major components of gases

produced were hydrogen, methane and carbon dioxide in molar ratios of 27%, 27% and 45%,

respectively. One of the author's research group has recently started an extensive study on

catalytic gasification of pulp/paper secondary sludge in SCW for hydrogen production. To the

best of the authors' knowledge, to date there is no other investigation worldwide that is

focused on the use of pulp/paper secondary sludge as feedstock for hydrogen generation.

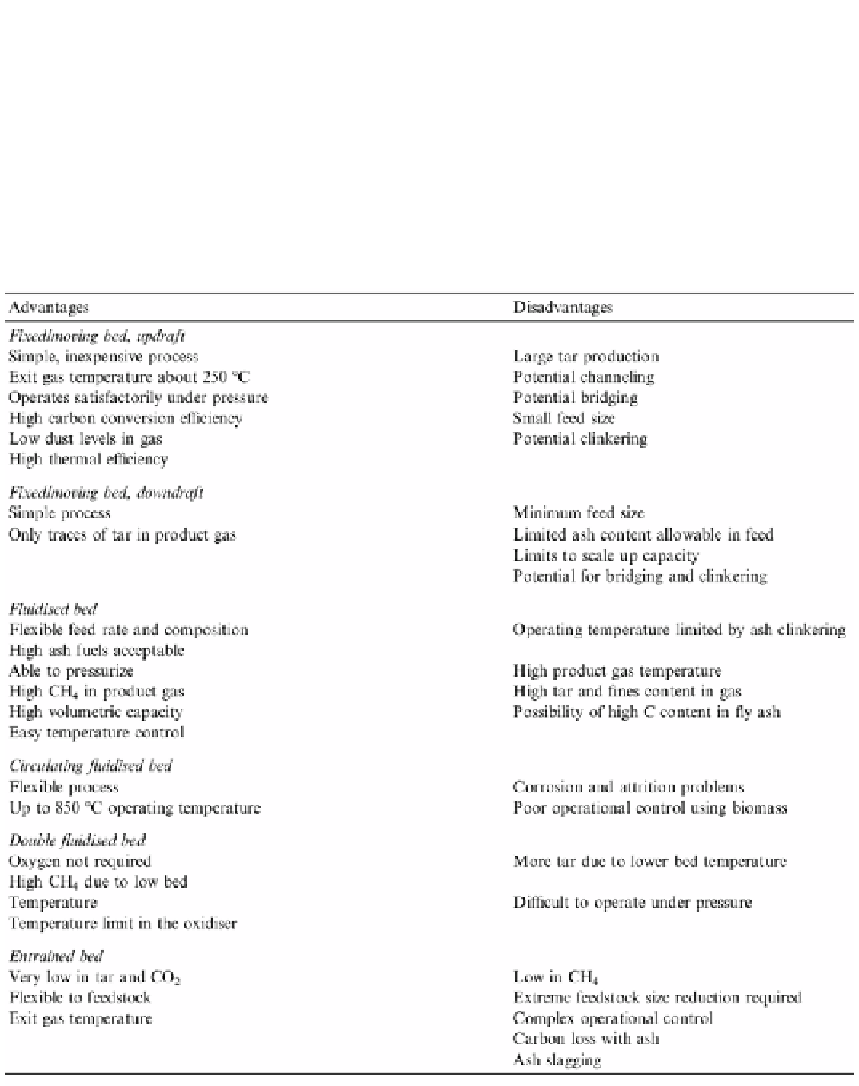

Table 3. Comparison of different types of gasifiers (Rampling and Gill, 1993).

Energy requirement in different stages of a typical gasification process is outlined in

Figure 5, including the location of energy inputs and outputs.

According to Ptasinkski et al. (2007), gasification of raw sludge is not very energy

efficient because the raw sludge contains a substantial amount of water (at as high as 98-99

wt%), and hence the optimal reaction conditions are difficult to achieve. In order to improve

the gasification efficiency, the moisture content of the sludge must be greatly reduced or dried