Environmental Engineering Reference

In-Depth Information

prior to being fed to a gasifier. According to Kim and Parker (2008), the energy consumption

required to dry thickened waste activated sludge (TWAS) containing about 10% TS to a dry

sludge at 105°C is about 2220 kJ/kg-ws. It may be possible to use the enthalpy of the

producer gas for drying the sludge and biomass feedstock for the gasification. However, the

gasification of pulp/paper secondary sludge is a relatively new method and hence not very

well documented so far, except for several reports on gasification of a mix of municipal

sewage sludge and coal and other domestic waste (Dinkel et al., 1991; Baumgartel, 1993). For

dry sludge, the gasification technology has shown to be an energy efficient process. For

instance, Hamilton (1998) reported that gasification of dried sewage sludge thermally with

the Lurgi-Rhurgas process based on a circulating fluidized bed produced 0.7 m

3

of fuel gas

per kg of dry sludge (DS), and the calorific value of the gas was as high as 22.7 MJ/m

3

, i.e., a

total energy output of about 16 MJ//kg-DS. With dry sludge used, the total process can thus

be energetically self-sustaining (Furness et al., 2000).

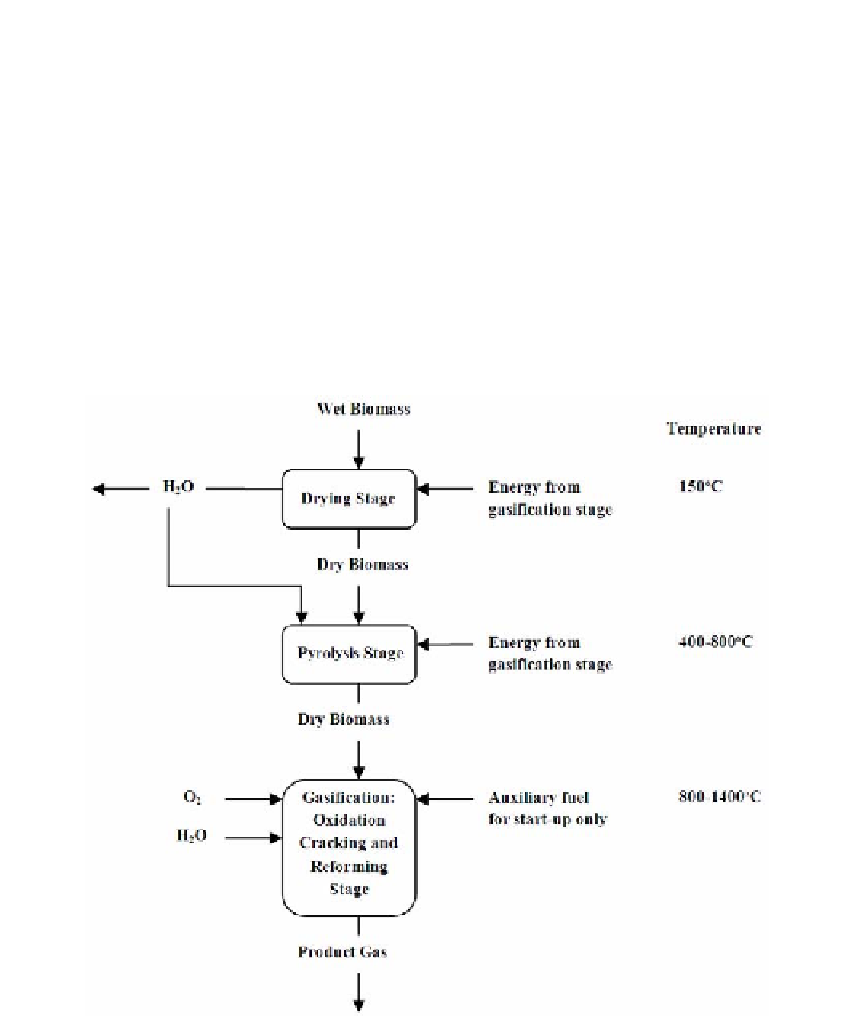

Figure 5. Energy requirement in different stages of a typical gasification process (modified from

Furness et al., 2000)

2.4. Direct Liquefaction

Due to the skyrocketed oil price and the increased concerns over greenhouse gas

emissions, there is a worldwide resurgence of interest in the production of liquid oil products

(e.g., bio-oils and bio-crude) from biomass through liquefaction. Fast pyrolysis, as described