Chemistry Reference

In-Depth Information

polystyrene lowers the Tg. When two polymers are miscible, they have a

single Tg which is intermediate between the Tg of each of the component

polymers. The greater the amount of polystyrene added, the lower the Tg of

the PPO blend. Rather than using polystyrene itself, Noryl uses high impact

polystyrene (HIPS). HIPS is prepared by polymerizing styrene in the presence

of polybutadiene, thereby forming a graft copolymer in with polybutadiene

and polystyrene homopolymer. There are different grades of Noryl, but a Tg

of about 150

∘

C is typical for this miscible blend.

Another blend, also invented at General Electric, is Xenoy

®

.Thisisan

immiscible blend of polybutylene terephthalate (PBT) and polycarbonate

(PC) [5, 6]. This blend is immiscible; it has separate phases of PBT and of

PC. An immiscible blend is characterized by two distinct Tgs and thermal

analysis of this blend shows the Tg of PBT and of PC as well as a sharp

melting point for the crystalline PBT. The blend also includes an impact

modifier. It exhibits the good impact associated with PC and the solvent

resistance associated with PBT. Because of these properties, it is suitable for

applications such as automotive bumpers requiring high impact and gasoline

resistance.

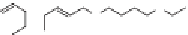

The carbonate linkage can react with the ester linkage in a transesterifica-

tion reaction. This reaction is illustrated by the reaction of diphenyl carbonate

with butylene dibenzoate to form phenyl benzoate.

O

O

O

catalyst

O

O

O

O

O

+

O

O

+

O

O

O

O

Diphenyl carbonate

Butylene dibenzoate

Phenyl benzoate

If this reaction proceeds in a PBT/PC blend, the two homopolymers react

and we get a blend that is miscible. This blend now no longer has two distinct

glass transition temperatures and has a broadened and depressed melting

point. The blend no longer has the desirable characteristics. It has poor

solvent resistance and is slow to crystallize, which causes poor injection

molding performance. For commercial blends, the transesterification reaction

must be controlled [7, 8].

There are many other commercial examples of polymer blends. Polycar-

bonate can be blended with an acrylonitrile-butadiene-styrene terpolymer

to give a PC-ABS blend. Polypropylene impact can be improved by

the addition of ethylene-propylene copolymers, which are sometimes

called ethylene-propylene-rubber (EPR). Ethylene, propylene, and a diene

monomer (EPDM), such as ethylidene norbornene, is also used to impart

impact and flexibility to polypropylene.

Search WWH ::

Custom Search