Chemistry Reference

In-Depth Information

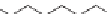

Caprolactam can be polymerized in the melt by use of a base and an activa-

tor. Two components, I and II, are used as starting materials. Component I is

a catalyst-containing lactam melt and component II is an activator-containing

lactam melt. The catalyst can be the sodium salt of caprolactam and the acti-

vator can be a derivative of caprolactam such as that prepared by the reaction

of caprolactam with acetic anhydride or a diisocyanate [19]. The following

example uses the derivative of caprolactam with hexamethylene diisocyanate.

N

O

O

O

C

O

N

N

+

N

N

C

H

N

O

Caprolactam

O

Activator

O

Na

+

Na

+

O

O

O

−

−

N

Caprolactam

O

N

N

N

+

N

R

N

R

O

O

Activator

Na

+

O

O

O

O

O

N

N

N

N

N

−

N

R

R

N

x

+

O

O

Nylon 6

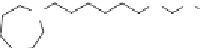

Nylons have hydrogen bonding and this causes relatively high melting

points for these crystalline polymers. The melting point of nylon 6,6 is 265

∘

C

and nylon 6 is 225

∘

C [20]. Also, due to its structure, nylon absorbs much more

water than many other plastics. For example, at 50% relative humidity, nylon

6,6 absorbs 2.8% (by weight) water and nylon 6, 3.0%. At saturation, nylon

6,6 absorbs 8.0% (by weight) water and nylon 6, 9.5%. Moisture absorption

in nylons with fewer amide bonds per weight, such as nylon 6,12 or nylon 12,

is lower. For example, nylon 12 absorbs 0.7% water at 50% relative humidity

and 1.4% at saturation [21]. The water acts as a plasticizer, lowers the T

g

,and

affects properties. Long-chain nylons are produced at a much smaller scale

and for specialized applications such as brake and gas lines that can bear the

higher cost. For example, shipments of nylon 6 and 6,6 together are about 6

million metric tons annually but the combined market for nylon 11 and nylon

12 is more than an order of magnitude less at 100,000 metric tons [22]. Com-

mon nylon tradenames are Stanyl

®

(nylon 4,6; DSM), Novamide

®

(nylon 6,

6,6; DSM) and Zytel

®

(Dupont).

Aromatic polyamides are called aramids. These are produced in much

lower volume than the aliphatic nylons, but because of their rigidity and high

heat capabilities, are useful in certain specialty applications. Probably the

two most common are the Dupont brands, Kevlar

®

and Nomex

®

. They can

Search WWH ::

Custom Search