Biomedical Engineering Reference

In-Depth Information

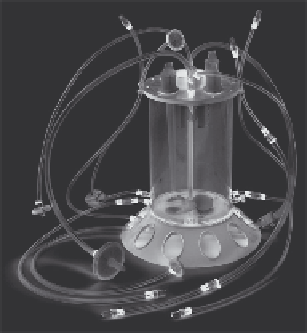

FIGURE 5.11

Mobius CellReady reactor.

Highlights and benefits • Superior mixing capabilities with highly

reduced shear stress • Innovative sparging device with better oxy-

genation and K

L

a • Adapted for cultivation of suspended or adher-

ent cells at very high densities • Compatible with most cell culture

processes • Scalable customizable system • No need for CIP/SIP

(disposable bag technology) • Avoid cross-contamination risks •

Very low working volume.

The Mobius CellReady 3 L bioreactor is equipped with a marine impeller

(top driven), a microsparger or open-pipe sparger, standard sensors, and an

Applikon ez-Control process control unit. Similar cell densities and anti-

body titers can be achieved in the Mobius CellReady, as in stirred 3 L glass

bioreactors. A comparable approach to the Mobius CellReady represents

New Brunswick Scientific's CelliGEN BLU single-use stirred-tank bioreactor

(Figure 5.11).

CellReady Bioreactor

Orbitally Shaken Single-Use Bioreactors

Orbitally shaken bioreactors are very difficult to study because of the free

movement of surfaces in the bioreactors. The surface-aerated CultiFlask 50

disposable bioreactor, a noninstrumented 50 mL centrifuge tube with a ven-

tilated cap, can deliver K

L

a values of between 5 and 30 per hour at CVs of 10

to 20 mL and agitation speeds between 180 and 220 rpm.