Biomedical Engineering Reference

In-Depth Information

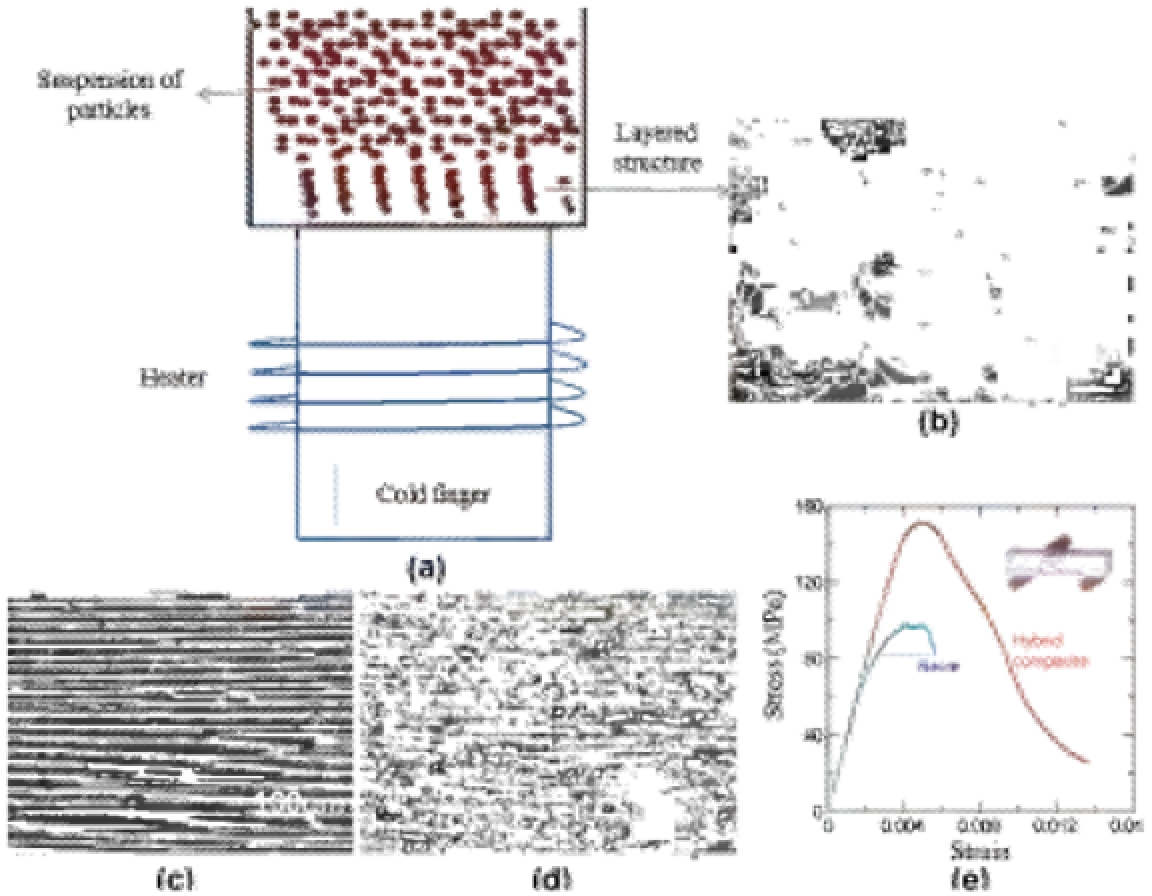

FIGURE 3.9

Freeze casting method to develop artificial nacres. (a) Schematic of the set-up, (b) aluminum oxide layers

after the ice layers are sublimated, (c) layered composite made of alumina layers (the lighter phase) filled with PMMA (the

darker phase), (d) the segmented layered structure resulted from compressing the layered composite, and (e) flexural stress-

strain behavior of the composite compared to that of nacre. Adapted from Ref.

54

.

3.4.2 Layer

-

by

-

Layer Assembly

Layer-by-layer (LBL) assembly is based on

sequential deposition of nanometers-thick lay-

ers of substances from oppositely charged com-

pounds

[56]

. The substances can be PEs, carbon

nanotubes, charged nanoparticles, biological

macromolecules, etc.

[56-62]

.

A substrate is coated with a sacrificial layer

and then is sequentially dipped into solutions of

oppositely charged substances with intermedi-

ate rinsing steps (

Figure 3.10

a). In each dipping

step, a layer of substances that have opposite

charge to the substrate is coated on the surface

by electrostatic interactions. For the case of arti-

ficial nacre, these substances can be nanoclays

and different polymers. After the layers are

coated, the sacrificial layer is dissolved so that a

stable freestanding film is developed. This film

is stabilized by ionic and hydrogen bonds, which