Biomedical Engineering Reference

In-Depth Information

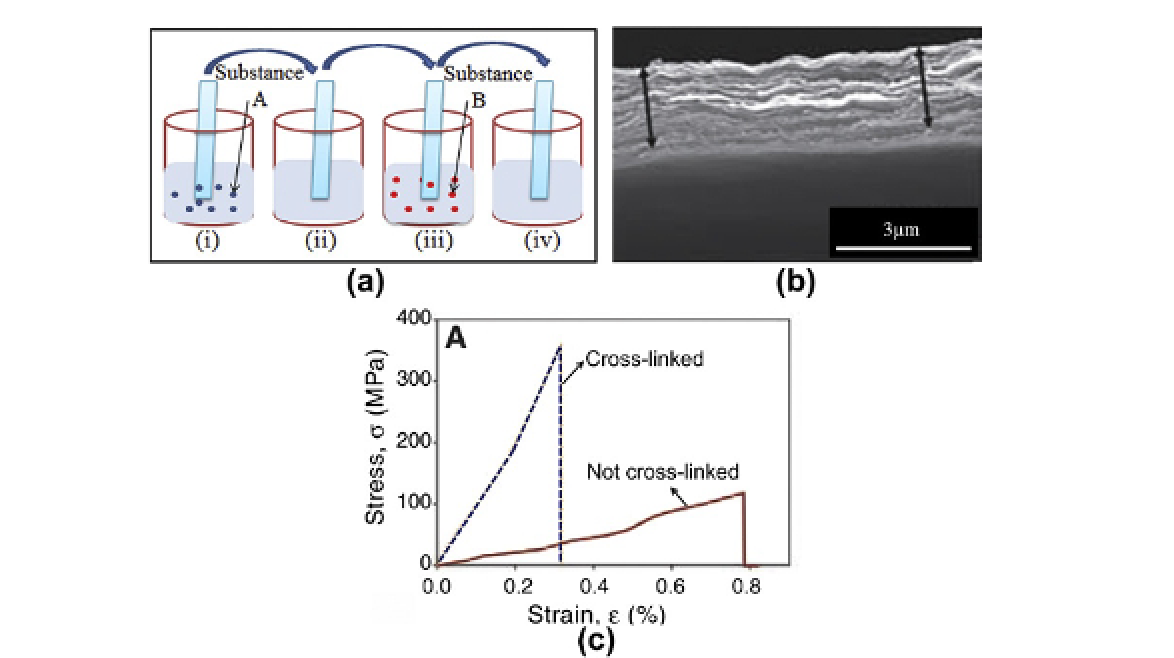

FIGURE 3.10

(a) The process plan for LBL assembly consists of sequential (i) dipping in substance A, (ii) rinsing,

(iii) dipping in substance B, and (iv) rinsing. (b) A cross-sectional scanning electron micrograph of a multilayered nano

particle/polymer composite fabricated by LBL assembly. (c) Tensile behavior of a PVA/MTM composite with and

without cross-linking. Adapted from Ref.

48

.

lead to an effective load transfer

[48, 58, 59]

. The

polymer can be cross-linked to incorporate

covalent bonds at the interface.

In addition to the possibility of manipulating

the interface behavior, this process has advan-

tages such as: (i) nanometer control over the

thickness of layers, (ii) ability to fabricate

homogenous films with little or no phase sepa-

ration, and (iii) incorporation of antimicrobial

properties and biocompatibility with the human

osteoblast for biomedical applications

[51]

.

However, for the case of artificial nacre, the

mechanical properties of the film degrade for

mineral concentrations higher than 15 %v/v.

Other main disadvantages are that it is a slow

process and there are practical limitations to the

maximum number of layers that can be

deposited.

The most successful artificial nacre fabricated

by this method is a PVA/MTM layered compos-

ite, which shows a strength of 10 times higher

than the organic phase (PVA) and an average

ultimate tensile strain of 0.7% (

Figure 3.10

b)

[48, 63]

.

Figure 3.10

c shows the tensile behavior

of the composite with and without cross-linking.

Covalent cross-linking at the interfaces increases

stiffness and strength at the expense of reducing

the extensibility of the material.

Another innovative technique is based on

sequential deposition of inorganic monolayers

formed at a liquid-gas interface followed by a

polymer coating stage. Submicrometer surface-

modified platelets are attracted to each other by

hydrophobic interactions at a water-air interface

to form an inorganic monolayer (

Figure 3.11

a)

[64]

. This monolayer is then deposited on a