Biomedical Engineering Reference

In-Depth Information

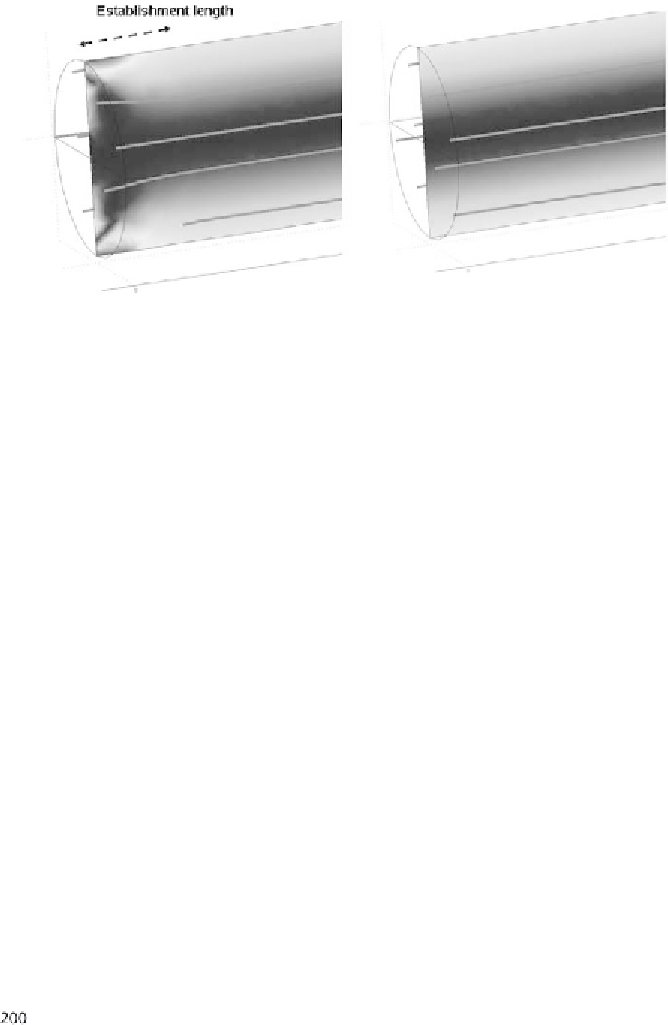

Figure 2.44

Vorticitycontourplotofanaxiallowinacylindricaltubeshowingtheestablishment

length.(a)Uniforminletvelocityand(b)inletvelocityieldgivenby(2.42).Thecontinuouslinesare

streamlines.

2.2.12 Distributing a Uniform Flow into a Microchamber

BioMEMS and immunoassays currently use microfluidic networks feeding the mi-

crochambers where the biological processes take place. Inside the capillary chan-

nels, the velocity profile is a Hagen-Poiseuille flow profile, parabolic for cylindrical

and rectangular channels, showing an important transverse gradient. For the pur-

poses of bioanalysis, labeled surfaces are installed inside the microchamber and it is

important that flow velocity should be as uniform as possible above all the labeled

surfaces. Labeled surfaces affected by a weak part of the main flow do not function

correctly.

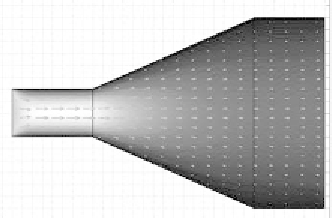

A simple design of a divergent cone between the capillary channel and the mi-

crochamber cannot be satisfactory because it would result in a very nonuniform

velocity flow profile in the microchamber. We have used the COMSOL software

[48] to solve the incompressible Navier-Stokes equation. Figure 2.45 shows that

the velocity profile in a cross section of the microchamber is nearly parabolic. The

conditions for correct functioning of the device are then not met.

If the divergent cone is separated in subchannels as shown in Figure 2.46, the

velocity profile is very much improved, at least in the middle part of the cross sec-

Figure 2.45

(a)Wideningfromamicroluidicchanneltoamicrochamber.(b)Nearlyparabolic

velocityproileinacrosssection,showingthatthemicrochamberwillnotbefedbyauniformluid

flow.