Agriculture Reference

In-Depth Information

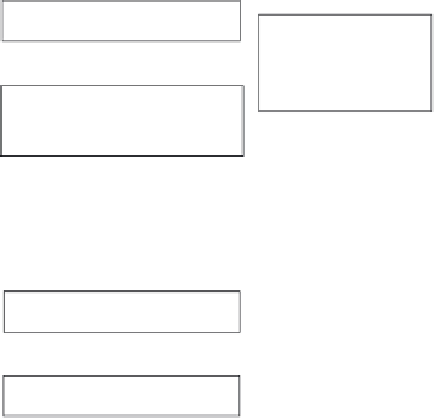

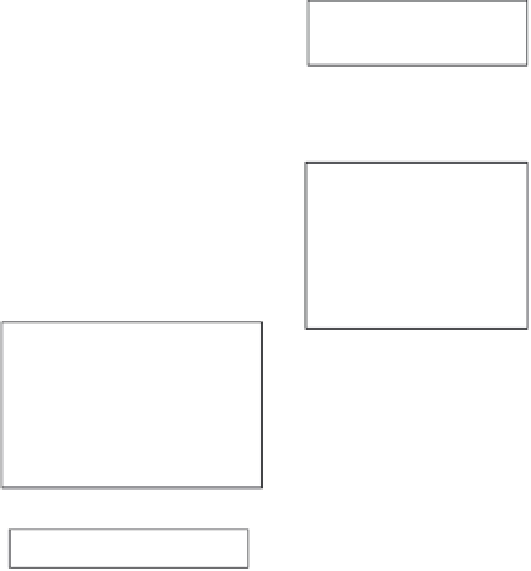

Kiwifruits

Kiwifruits (70% ripeness)

Peeling

Crushing

Cutting (6-8 cuts,

thickness 5-7 mm)

Sieving (0.1 cm dia.)

Add 15% sugar

and 500 mg/kg

sulfur dioxide

Mixing with apple

juice (1:1)

Add vitamin C to

maintain the color

Washing in hot water

(90-95

o

C, 6-10 min.)

Drying (45

o

C, 15 h)

Washing and cooling

(10-15 min.)

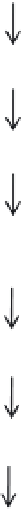

3 stages of soaking: 1

st

Brix 20-25; 2

nd

Brix 30-

35; 3

rd

Brix 40-45

T: 50-60

o

C; 3.5-4h

Acidity:4g/L after

soaking

Rolling

Vacuum soaking in sugar

(2.1:1=sugar solution:fruits)

Packaging

Simmering and Baking

1

st

stage 50-53

o

C, 1.5 h,

de-moisturizing for 5 min.

2

nd

stage 70-75

o

C, 2-3 h

3

rd

stage 78-80

o

C, 3-4 h

Final moisture: 18-20%

Figure 25.7.

Diagram depicts the processing steps

for the production of kiwifruit leather (depicted

based on information from Pan, 1993).

loss of nutrients through electrolyte leakage and oxidation

breakdown.

Postharvest can result in substantial losses in nutritional

quality, particularly vitamin C content and some phyto-

chemical. For example, gradual decrease in ascorbic acid

(AA) can occur concomitantly with an increase in dehy-

droascorbic acid (DHA) during the storage of kiwifruit

slices at 5

◦

and 10

◦

C (Agar et al., 1999). The total vitamin

C losses in kiwifruit slices after 6 days of storage at 0

◦

,5

◦

,

and 10

◦

C are 8%, 13%, and 21%, respectively. Only 10%

of AA remains in kiwifruit slices after 10 days of storage

at 2

◦

C (Agar et al., 1999). The application of AA and/or

CaCl

2

is effective in preserving or improving the antioxi-

dant activity of sliced kiwifruit during storage at 2

◦

C. The

CaCl

2

remains effective in preserving the antioxidant ac-

tivity up to 8 days of shelf life (Antunes et al., 2010). The

effects of processing and storage on the quality indices and

nutritional content of fresh-cut fruits are evaluated in com-

parison to the whole fruits. The postcutting shelf life based

on visual appearance is less than 6 days for kiwifruit slices,

and loss of vitamin C (12%) was reported, though no loss

in carotenoids and phenolics have been noted after 6 days

at 5

◦

C (Gil et al., 2006).

Packaging

Figure 25.8.

Diagram depicts the processing steps

for the production of kiwifruit preserve (drawn

based on information from Pan, 1993; Huang et al.,

2007).

Study on effect of processing has been mainly fo-

cused on vitamin C stability due to its prominence. Lit-

tle portion of green-fleshed kiwifruits is preserved as fruit

juice/concentrate, puree, or dried fruit products to prolong

the shelf life using different processing methods. Some

studies have found vitamin C degradation in kiwifruits due

to thermal processing. For example, more than 50% of vi-

tamin C degradation occurred after concentrating kiwifruit

juice with osmotic distillation (Cassano and Drioli, 2007)

and drying (Kaya et al., 2010). Similar to conventional ther-

mal processing, radiation could also affect the stability of

vitamin C in kiwifruit, depending on the dose applied. At

low dose (up to 0.6 kGy), vitamin C content in kiwifruit can

be maintained (Kim and Yook, 2009; Harder et al., 2009).

However, higher dosage jeopardizes the stability of vitamin

Search WWH ::

Custom Search