Agriculture Reference

In-Depth Information

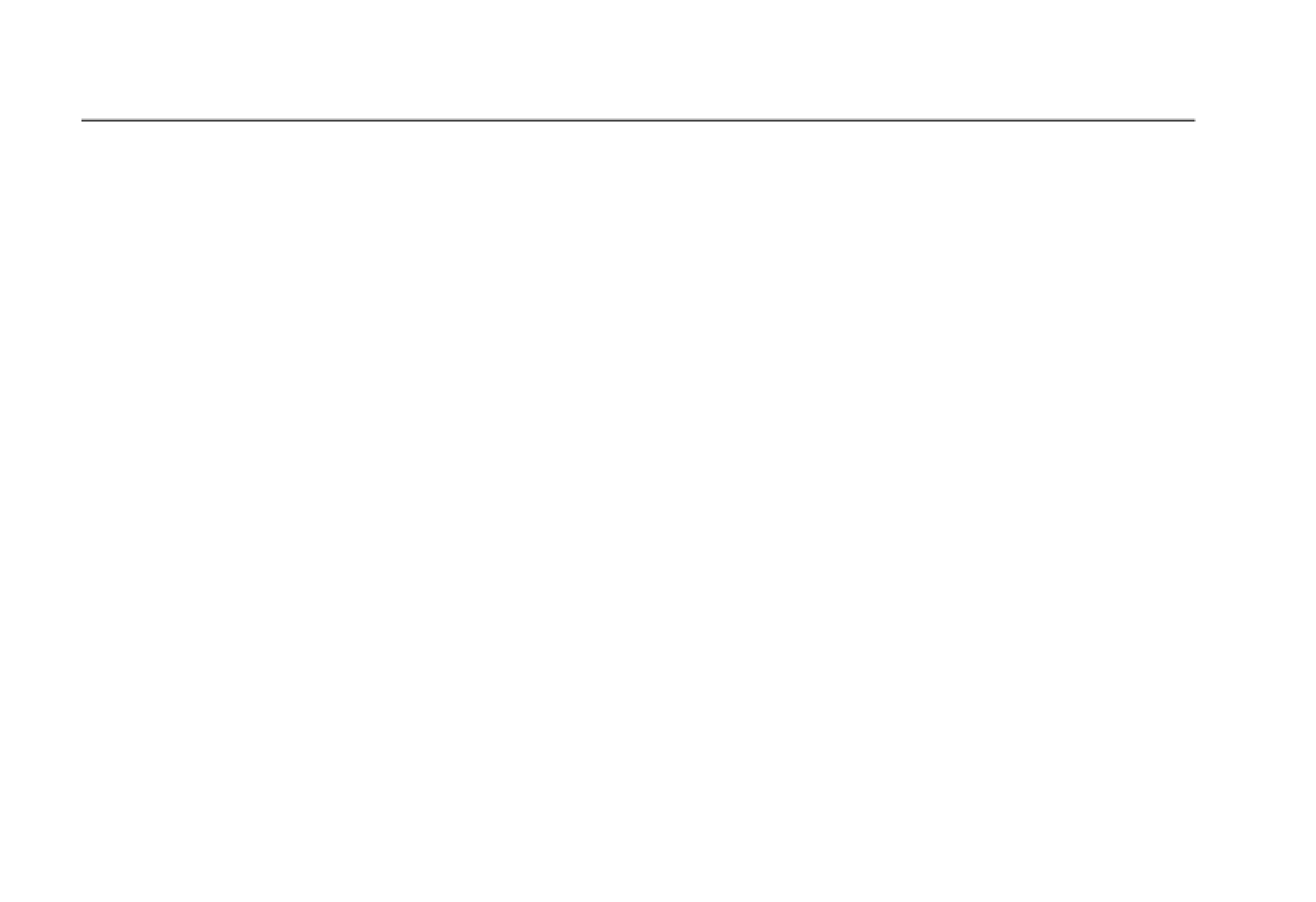

Table 6.3.

Critical control points, critical limits, process control, corrective actions, and verification in mango production

Responsible

personnel

Corrective

action

CCP

Critical parameter

Way

Frequency

Control sheet

Verification

CCP 1

When the first fruit shows

color on tree, all of that

size fruit or larger may

be removed; repeat

when remaining fruit

show color. Do not store

below 10

◦

C.

Temperature control

Daily per harvest

Control of

incoming raw

material

Warehouse

manager

Immediate

cooling

Daily

verification

CCP 2

Storage at room

temperature

Control and

recording of

temperature and

relative humidity

Daily

Recording meter

Waterhouse

manager

Adjustment

of faults

Monthly

verification

CCP 3

Concentration of

disinfectant in washing

water

Control of

disinfectant

At every product

change during

cleaning

Control sheet of

line washers

Production

manager

Prewashing

−

do

−

−

do

−

1

−

do

−

CCP 4

Control of disinfectant

Control of

disinfectant

At every product

change during

pasteurization

Control sheet of

pasteurization

line

Adjustment

of faults

CCP 5

Temperature control

Control of

disinfectant

Daily

Recording meter

−

do

−

Adjustment

of faults

−

do

−

CCP 6

Weight control

Weighing the fruit

At every product

change

Control sheet

−

do

−

Adjustment

of faults

−

do

−

CCP 7

Temperature of freezing

must be low

Measurement of

temperature

−

do

−

Control sheet of

packaging line

−

do

−

Final

product

control

−

do

−

CCP 8

Storage temperature must

be low

Control and

recording of

temperature

At each loading

Control sheet of

final products

Quality

control

supervisor

Control

suspicious

lots

−

do

−

1

Same as above

Search WWH ::

Custom Search