Agriculture Reference

In-Depth Information

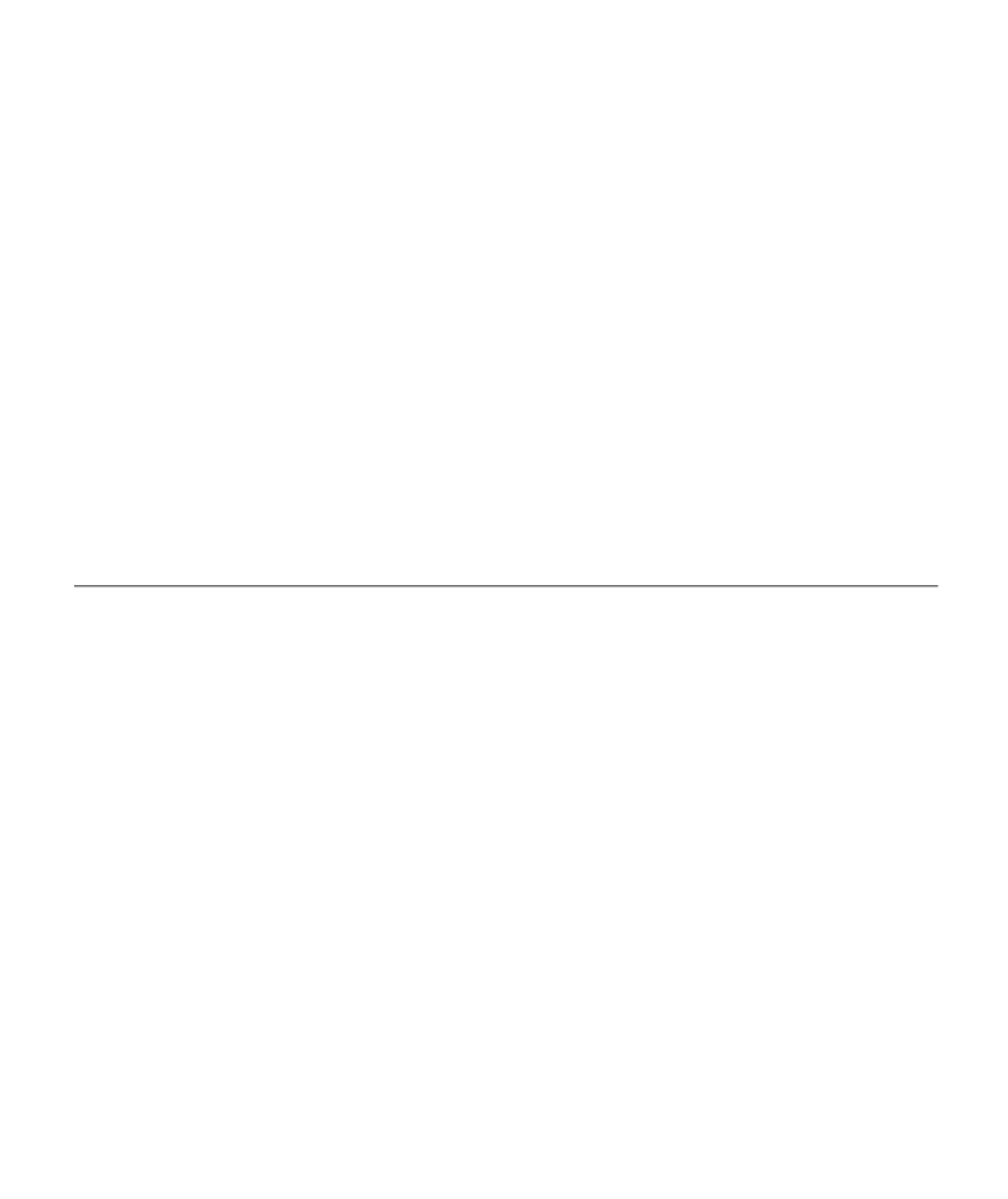

Table 6.2.

ISO 22000 analysis worksheet for determination of the prerequisite programs in mango

production

Do they

contribute to

controlling

recognizable

food safety

hazards?

Are the technical

infrastructure and

the preventive

maintenance

program adequate?

Does the

effectiveness of the

remaining control

measures depend

on them?

Is it

feasible to

evaluate

them?

Is it a

prerequisite

program?

Processing step

Fruit reception

Yes

Yes

No

No

No

Storage

Yes

Yes

No

Yes

Yes

Washing

Yes

Yes

No

No

No

Tip cutting

Yes

Yes

No

Yes

Yes

Sorting

Yes

Yes

No

Yes

Yes

Brushing

Yes

Yes

No

Yes

Yes

Destoning

Yes

Yes

No

Yes

Yes

Pasteurization

Yes

Yes

Yes

No

No

Cooling

Yes

Yes

No

No

No

Filling

Yes

Yes

No

No

No

Freezing

Yes

Yes

No

No

No

Packaging and coding

Yes

Yes

No

Yes

Yes

Palletization

Yes

Yes

No

Yes

Yes

Storage

Yes

Yes

No

Yes

Yes

Container loading

Yes

Yes

No

No

Yes

Transportation

Yes

Yes

No

No

No

parameters involved. The remaining stages, such as pack-

aging and cooling, palletization, container loading, and

transportation, are not CCPs according to the CCP tree

diagram.

Because all hazards have already been reported per stage,

the next step is to answer the HACCP tree diagram for deter-

mining the CCPs. Table 6.1 provides the answers to the four

questions, and as a result, there are ten CCPs. In fact, the

most important are the thermal and cooling processes, in-

cluding tip cutting, destoning, and filling weights. Table 6.2

gives the answers to the four questions with respect to the

application and effectiveness of PRPs in mango production.

To be more specific, the application of PRPs results in only

four CCPs (fruit reception, pasteurization, deep cooling,

and transportation). CCPs, critical limits, processing con-

trols (frequency, way, corrective actions) for all stages of

mango production are given in Table 6.3. Finally, a synop-

tic presentation of hazards and preventive actions in mango

production is given in Table 6.4.

on breaking off the fruits without injuring it, drying the

fruit if it is moist, maintenance of proper transportation

temperatures, and cleaning and disinfecting transportation

vehicles to avoid cross-contamination. In view of the high

number of potential hazards and the fact that application

of the CCP tree diagram indicated a CCP, an attempt was

made to check whether all the previously mentioned haz-

ards could be eliminated by means of PRPs. Although sev-

eral hazards could be effectively eliminated with appro-

priate training of personnel, such as breaking off the fruit

and cleaning and disinfecting transportation vehicles, the

transportation temperature always remains a CCP. Stack-

ing of packages and pallets is a potential hazard if they

are overfilled or too many have been stacked. Although,

according to a typical hazard analysis (tree diagram with-

out PRPs), stacking is a CCP, proper and repetitive training

can eliminate this hazard (ISO 22000). Transportation of

pineapples from harvesting place to packinghouse is a CCP

because of potential temperature abuse that will have to be

continuously recorded. The next stages—unloading of con-

tainers, floating of pineapple in water, and precooling—are

not CCPs because the hazards involved either do not affect

pineapple safety or there was a later stage during which

Case Study: Pineapple

Figure 6.4 shows a flow diagram for fresh pineapple han-

dling and marketing. The hazards in harvesting are focused

Search WWH ::

Custom Search