Agriculture Reference

In-Depth Information

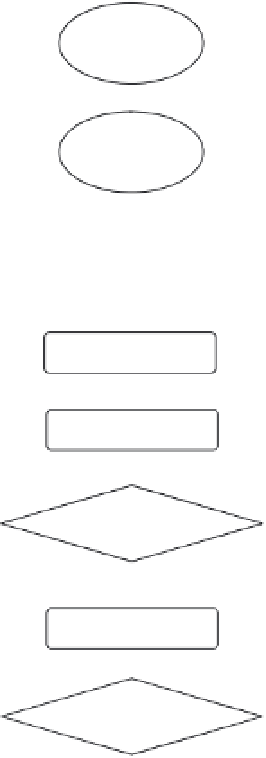

Prepare a flow chart of the operation of fruit processing.

This should be a step-by-step flow chart.

- Verify the steps and identify the hazards at each step.

- Record all sources of ingredients to establish traceable

connections to eliminate hazard sources.

HACCP for tropical fruit processing

To maintain the quality of tropical fruits, the entire produc-

tion chain from harvesting to handling, storage, processing,

and distribution should follow quality regulations strictly.

Generally, the HACCP concepts for most of the tropical and

subtropical fruits and their processing are similar.

Display the critical control points and repeat the review

of actions taken periodically, such as daily, weekly, and

monthly.

Case Study: Mango

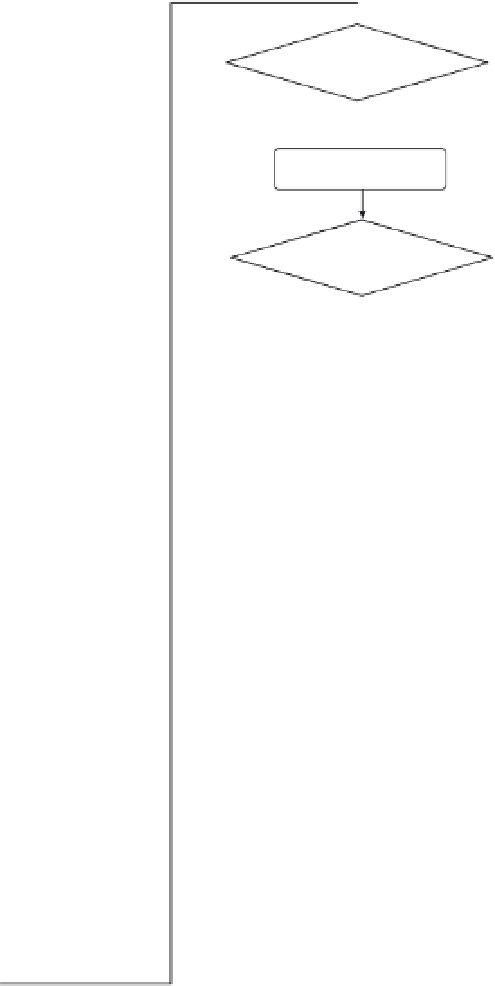

A representative flow diagram of mango processing is

given as Fig. 6.3. The hazards in fruit reception include

bruises, soft tissues, enzymatic browning, micro-organism

growth, and pesticide residues. The goal of the quality

Standardize procedures and update them as frequently

as possible with new techniques.

Ensure that management approves and signs records of

inspection regularly.

Mango

harvesting

Is deep-cooling

satisfactory?

Reject

NO

YES

Transportation

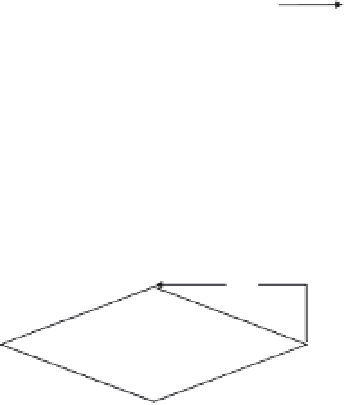

Filling

Is the fill-weight

appropriate?

NO

Reject

Fruit receiving

YES

NO

Weighing & storage

Are the freezing

temperatures

appropriate?

Washing

NO

YES

Is tip cutting

satisfactory?

Labeling & palletization

YES

Sorting & brushing

Are the storage

temperatures

appropriate?

Reject

NO

Is destoning

satisfactory?

Reject

NO

YES

YES

Container loading

Pulping

NO

Is pasteurization

satisfactory?

Transportation

to markets

YES

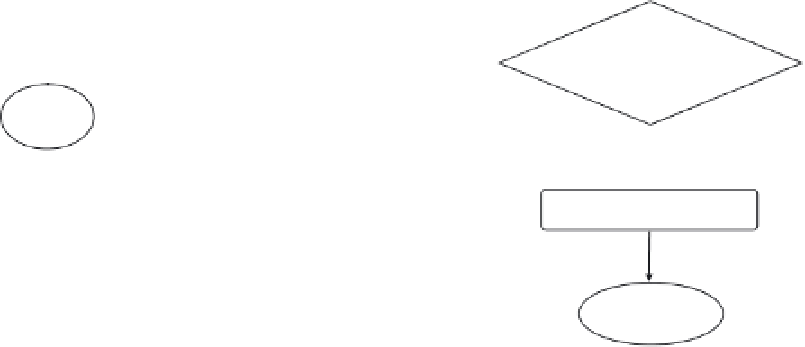

Figure 6.3.

Flow diagram of mango processing.

Search WWH ::

Custom Search